We are Venturi tube type rh manufacturer in India

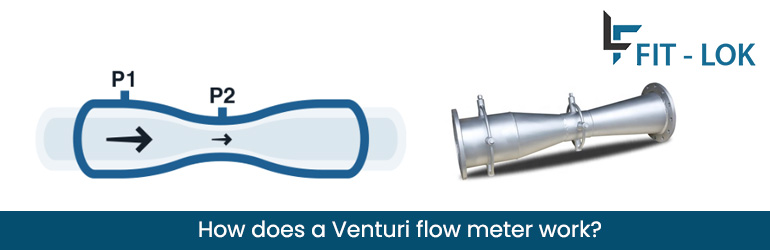

Venturi flow elements are used to measure fluid flow in pipelines. They are also known as venture flow elements. They are made up of three sections: a converging inlet, a throat, and a diverging output. The flow of fluid is restricted at the throat, resulting in a reduction in pressure. The flow rate of the fluid is determined by the differential pressure between the intake and output parts of the flow element.

Why pay extra? Buying from Pipe flow measurement suppliers saves your cost

Venturi tubes of type RH are ideal for measuring low-velocity liquid and gas flows. They’re often found in water treatment plants and chemical processing plants. Hastelloy C276 Venture Flow Elements are ideal for sensitive applications because they allow highly accurate flow metering. Venturi tubes feature a low pressure drop when compared to other flow monitoring devices, which helps to save energy usage and costs. Venturi tubes are simple to install and maintain, reducing downtime and maintenance costs.

Table of content

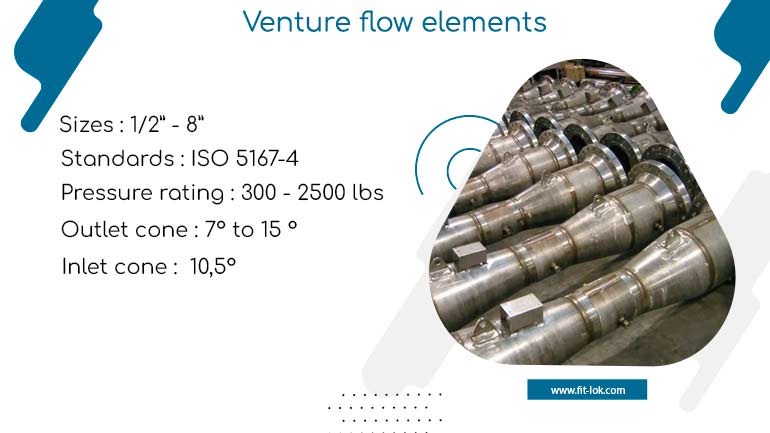

| Sizes : | 2” to 8”, DN 50 to DN 200 according to ISO or TR 15377. |

| Mounting style : | according to ANSI B16.25 or EN 9692-1 Weld ends. as per ANSI or DIN B16.5 standards Flanges. |

| Material : | AISI 316, Carbon steel, 254 SMO, Duplex others on request. |

| Design Standards : | ISO 5167-4, ISO/TR 15377, ASME MFC-3M |

| Pressure rating : | 300 – 2500 lbs, PN 40 to PN 640, ISO PN 50 to PN 420. |

| Tapping hole size : | 4 mm |

| Outlet cone : | 7° to 15 ° |

| Pressure taps : | 26.9 mm, Ø 21.3 milimeter Weld ends , thread connection 3/8″, 1/2″ NPT, 1/2″ BSP or flanged. |

| Inlet cone : | 10,5° |

Venture flow elements

Venturi tube type rh

Pipe flow measurement

| Component | Corner Tap Venturi | Static Tap Venturi |

|---|---|---|

| Increaser | 12 | 5 |

| Elbow | 15 | 9 |

| Reducer | 3 | 2.5 |

- Coefficient of discharge is high

- Can be installed vertically, horizontally, or inclined

- Pressure drop is low

- Less susceptibility to damage

- Occupies more space

- Highly expensive

- The device cannot measure pressure at velocity levels higher than its maximal operational range.

Venturi Tube is constructed with smaller converging cross section at the inlet and a diverging outlet. In these tubes flow of fluid is always go from larger section to smaller section through the neck.

Upstream inlet is connected with high pressure port of the differential pressure transmitter and downstream outlet of the tube is connected to the low-pressure port.

When fluid enters into the instrument its velocity increases and pressure decreases.

| Process pressure | max. 350 bar / 5077 psi |

|---|---|

| Process temperature | -175°C…+720°C / -283°F…+1328°F |

| ISO 5167-1&4 | ASME MFC-3M | |

|---|---|---|

| Reynolds number in the pipe | ReD > 2.10 5 | 2.10 5 ≤ ReD ≤ 6.106 |

| Inside pipe diameter | 50 mm ≤ D ≤ 250 mm | |

| d/D | 0,4 ≤ β ≤ 0,75 | 0,3 ≤ β ≤ 0,75 |

| Throat roughness | Ra ≤ 104 .d | |

| Convergent and entrance cylinder roughness |

Ra ≤ 104 .d | |

| Entrance cylinder minimum length | l = D | |

| Inlet convergent length | l’ = 2,7.(D – d) | |

| Angle of the inlet convergent | α = 21° ± 1° | |

| Throat length | lc = d ± 0,03.d | |