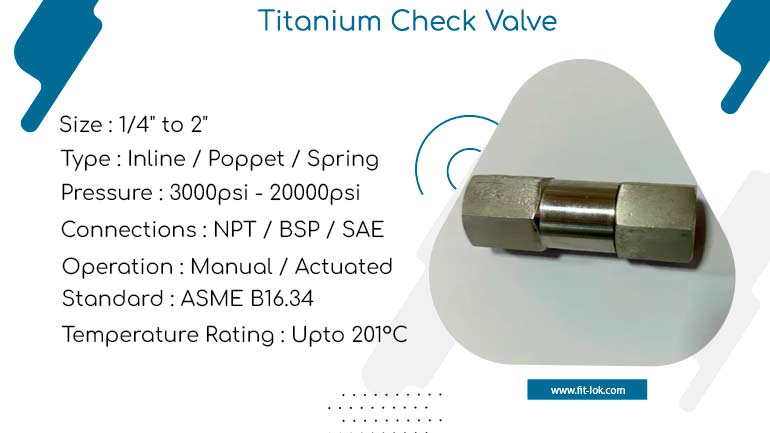

Biggest Titanium Grade 2 Check Valves manufacturer in India

Buy UNS R50400 inline check valves at factory price in size range of 1/2″ to 2″

Table of content

- Titanium Check Valve Specification

- Price list of Titanium Alloy Check Valve

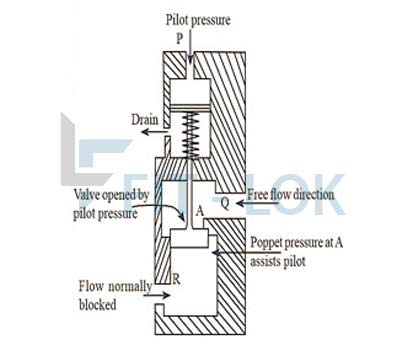

- Ti Instrument Check Valve types

- Drawing of Titanium Grade 2 Check Valves

- Ti alloy Piston Check Valve chemical composition

- Ti Spring Check Valve mechanical properties

- Titanium Control Check Valve equivalent grade

- Titanium Grade Piston Check Valve Physical Properties

- Dimensions of Titanium Grade 5 Check Valve

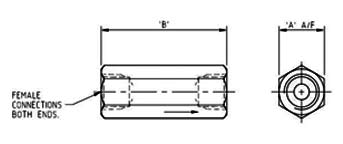

- Ti Alloy Gr 2 Female to Female Check valve dimensions

- Advantages and Disadvantages of UNS N56400 spring check valve

- Applications of UNS R50400 inline check valves

- Parts of WERKSTOFF NR. 3.7035 Spring Check Valve

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Buy UNS N56400 spring check valve from manufacturer at factory price

Price of Titanium grade 2 Inline Check Valve vary between 15$ to 150$ per piece based on size, material, pressure rating, design and flow rate. For updated price list of UNS N56400 Instrument Air Check Valve you can contact us on sales@fit-lok.com

Titanium Hydraulic Check Valve

Titanium grade 2 Inline Check Valve

Ti alloy Gr 5 Nrv Valve

UNS N56400 Instrument Air Check Valve

Titanium grade 5 Non Return Valve

Titanium Alloy Spring Check Valve

UNS R50400 Instrumentation Check Valve

DIN 3.7035 Poppet Check Valve

ASTM B348 Grade 2 Instrument Control Valve

| Grade | Ti | O | Fe | H | C | N | V | Al |

|---|---|---|---|---|---|---|---|---|

| Ti Grade2 | 99.2 min | 0.25 max | 0.3 max | 0.015 max | 0.1 max | 0.03 max | – | – |

| Ti Grade5 | 90 min | 0.2 max | 0.25 max | – | – | – | 4 min | 6 min |

| Element | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

|---|---|---|---|

| Titanium Gr. 2 | Psi – 39900 , MPa – 275 | Psi – 49900 , MPa – 344 | 20 % |

| Titanium Gr. 5 | Psi – 128000 , MPa – 880 | Psi – 138000 , MPa – 950 | 14 % |

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr. 2 | 3.7035 | R50400 |

| Titanium Gr. 5 | 3.7165 | N56400 |

| Element | Density | Melting Point |

|---|---|---|

| Titanium Gr. 2 | 4.5 g/cm3 | 1665 °C (3030 °F) |

| Titanium Gr. 5 | 4.43 g/cm3 | 1632 °C (2970 °F) |

Refer dimensions and pressure rating of Ti alloy Piston Check Valve

| Thread Size | Max Pressure | ‘A’ A/F | ‘B’ | Cracking Pressure | Weight |

| 1/4″ | 6,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.2kg |

| 1/4″ | 10,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.3kg |

| 3/8″ | 6,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.3kg |

| 3/8″ | 10,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.8kg |

| 1/2″ | 6,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.2kg |

| 1/2″ | 10,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.3kg |

| 3/4″ | 3,000 PSI | 1.3″ | 3 5/8″ | 4 PSI | 0.3kg |

| 3/4″ | 6,000 PSI | 1.5″ | 3 5/8″ | 4 PSI | 0.8kg |

| 1″ | 3,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| 1″ | 6,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| END CONNECTIONS | PRESSURE RATING 100°F (37°C) PSIG | Hex | Length | |

| INLET / OUT LET | (mm) | (mm) | ||

| 1/8″ NPT F | 1/8″ NPT F | 15000 psi | 19 | 55 |

| 1/4″ NPT F | 1/4″ NPT F | 15000 psi | 22 | 58 |

| 3/8″ NPT F | 3/8″ NPT F | 15000 psi | 25 | 65 |

| 1/2″ NPT F | 1/2″ NPT F | 15000 psi | 27 | 72 |

| 3/4″ NPT F | 3/4″ NPT F | 15000 psi | 36 | 82 |

| 1″ NPT F | 1″ NPT F | 15000 psi | 45 | 85 |

We are leading Titanium Grade 5 Check Valve stockist and distributor in Mumbai

Advantages

- Corrosion Resistance

- Lightweight

- High Strength-to-Weight Ratio

- Durability

- Temperature Resistance

- Biocompatibility

Disadvantages

- High Cost

- Difficult to Machine

- Brittleness in Certain Conditions

- Limited Repairability

- Compatibility Issues

- Food and Beverage Industry

- Automotive Systems

- HVAC Systems

- Oil and Gas Industry

- Air and Gas Systems

- Pharmaceutical Industries

- Offshore Applications

| Name | Material |

|---|---|

| Disc | CF8M |

| Body | CF8M |

| Cap | CF8M |

| Disc Bolt | Titanium |

| Gasket | TEFLON |

| Bolt Washer | TEFLON |

| Pin | Titanium |