Leading Q Type Syphon Manufacturer in India

What is Pressure Gauge Siphon?

It is a simple device to protect a pressure sensor from high temperature media. Its also reduces the effect of rapid pressure changes which might possibly damage the instrument.

High Pressure Gauge Syphon can protect your instrument at elevated temperature.

Key functions of Sipon Pipes are as below:

- Protecting Pressure Instruments

- Sealing Against Noxious Gases

- Controlling Fluid Flow

Table of content

| SIZE | 1/8″ TO 1″ |

| Thread types | NPT / BSPT / BSPP / MxM / MxF / F×F |

| THREADS | NPT, BSPP, BSPT, METRIC, JIC, UNF |

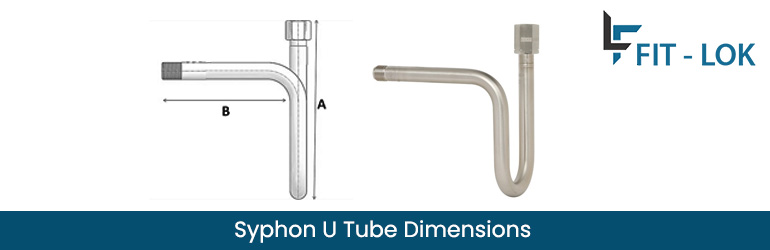

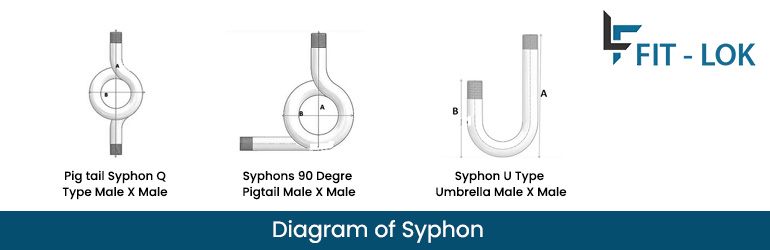

| Types | U-Type, U-Type UMBRELLA, Q-Type Pigtail |

| PIPE SCH | SCH 40, SCH 80, SCH 160 |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI |

| Pipe Type | Seamless, Welded |

| Standards | DIN 16282 |

| Schedule | Sch 40 / Sch 80 / Sch 160 / Sch XXS |

| Testing | Hydrostatic / pneumatic per spec |

Syphones

Q Type Syphon

High Pressure Gauge Syphon

- Compact version suitable for vibration applications

- measuring instruments (hook-up) on request Permissible temperatures to 550 °C

- Nominal pressures to 420 bar

- Customer-specific combination of valves and

| Size (Outlet) | Size (Inlet) | A | B |

| 1/4″ NPT Male | 1/4″ NPT Male | 180 | 120 |

| 3/8″ NPT Male | 3/8″ NPT Male | 190 | 130 |

| 1/2″ NPT Male | 1/2″ NPT Male | 200 | 150 |

| 3/4″ NPT Male | 3/4″ NPT Male | 200 | 150 |

| 1/4″ NPT Female | 1/4″ NPT Male | 180 | 120 |

| 3/8″ NPT Female | 3/8″ NPT Male | 190 | 130 |

| 1/2″ NPT Female | 1/2″ NPT Male | 200 | 150 |

| 3/4″ NPT Female | 3/4″ NPT Male | 200 | 150 |

Refer price list and Installation process of Syphon U Tube

| Product | Price in USD | Price in Dirham | Price in Euro |

|---|---|---|---|

| 7.5mm Siphon Tube, AISI 304 | 2.10 | 7.71 | 1.81 |

| 50mmx1.5m Siphon Pipe, SS 316 | 3.24 | 11.90 | 2.80 |

- Fluid Properties

- Flow Rate and Pressure

- Environmental Conditions

- Chemical Exposure

- Temperature and Soil Conditions

Specifically, the performance of siphons requires proficient installation to guarantee success. Here are essential steps to follow:

- Choose the Right Location: Make sure that the pipe is at the right height and in a direct line.

- Seal Joints Properly: To help avoid leakage, make sure all joints are well fastened to avoid setting in of any water leakage.

- Check for Air Traps: Make sure that small dead space which can have some negative impact on performance is eliminated.

Siphon Tube can withstand wide range of temperature and pressure in different media.

| Temp (ºF) | 316 SS Schedule 40 (PSI max) | 316 SS Schedule 80 (PSI max) |

|---|---|---|

| 20 to 100 | 1192 | 2580 |

| 200 | 1117 | 2419 |

| 300 | 991 | 2145 |

| 400 | 909 | 1967 |

| 500 | 842 | 1822 |

| 600 | 797 | 1725 |

| 650 | 782 | 1693 |

| 700 | 767 | 1661 |

| 750 | 752 | 1629 |

| 800 | 737 | 1596 |

| 850 | 737 | 1596 |

| 900 | 730 | 1580 |

| 950 | 722 | 1564 |

| 1000 | 715 | 1548 |

| 1050 | 708 | 1532 |

| 1100 | 705 | 1541 |

| 1150 | 632 | 1406 |

| 1200 | 480 | 1068 |

| 1250 | 358 | 796 |

| 1300 | 267 | 593 |

| 1350 | 198 | 441 |

| 1400 | 145 | 322 |

| 1450 | 114 | 254 |

| 1500 | 84 | 186 |