SS 304 U Bend Tubing supplier in India

Our Stainless Steel Fin Tube Heat Exchanger are designed to withstand high temperatures and pressure, making them suitable for demanding industrial applications.

Table of content

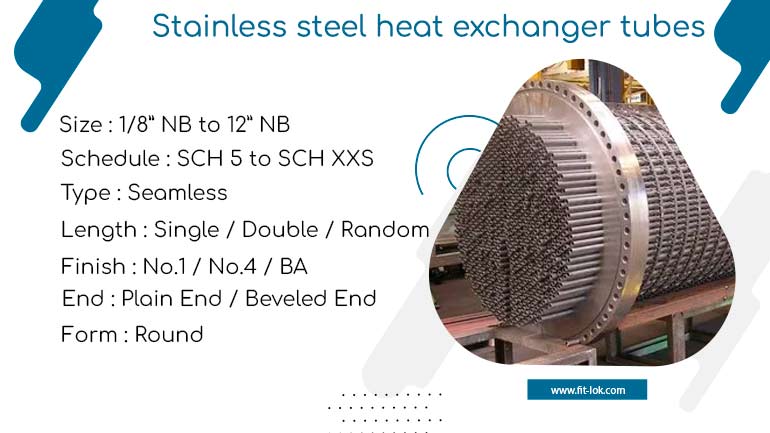

- Stainless Steel Heat Exchanger Tube Specification

- Stainless Steel Superheater Tube Types

- SA 213 Heat Exchanger Tubes Size Range

- Features of SS 304 U Bend Tubing

- Stainless Steel Fin Tube Heat Exchanger Chemical Compostion

- ASTM A213 heat exchanger tube Mechanical Properties

- Equivalent of SS Finned Tube Heat Exchanger

- 316l Stainless Steel Heat Exchanger Dimension Tolerance

| Specification | ASTM A269/ ASME SA 269, ASTM A249/ ASME SA 249, ASTM A789/ ASME SA 789 |

| Wall Thickness Range | 0.5 To 5 mm |

| Size Range | 6.53 to 127 mm |

| Tolerance | +/-0.05 Mm |

| Length | up to 20 Meter |

| Bending radius | 1.25 x Outer Diameter up to 1700mm |

| Processing Service | Welding, Cutting, Bending, Decoiling, Punching, Moulding |

| END | Beveled End, Plain End, Treaded |

| Delivery Condition | Bright Annealed, Annealed and Pickled, Cold Drawn, Polished, MF |

| Technique | Cold rolled, Hot rolled, Cold drawn, Extrusion Tube |

Stainless Steel Superheater Tube

TP316 Seamless U Tube

Stainless Steel Fin Tube Heat Exchanger

SS Finned Tube Heat Exchanger

316l Stainless Steel Heat Exchanger

304 Stainless Steel Heat Exchanger

- Range : 10 mm OD to 50.8 mm OD

- Wall Thickness : 0.70 mm to 8.00 mm

- Outer Diameter : 6.00 mm to 101.60 mm

- Length : up to 20 m (65.62 ft) Length & Customed Required Length

Choose a SS Finned Tube Heat Exchanger supplier that specializes in customized solutions, offering tailored sizes and pressure ratings for your unique needs

- according to specifications and applications

- solutions that are specialised for each application

- systems that are fully automated for effective and seamless functioning

- developed with cutting-edge software

| Grade | Carbon | Manganese | Silicon | Phosphorus | Sulfur | Chromium | Molybdenum | Nickel | Nitrogen | Titanium | Iron | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 304 | Minimum | 18.0 | 8.0 | |||||||||

| Maximum | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | 0.10 | ||||

| 304L | Minimum | 18.0 | 8.0 | |||||||||

| Maximum | 0.030 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 12.0 | 0.10 | ||||

| 304H | Minimum | 0.04 | 18.0 | 8.0 | ||||||||

| Maximum | 0.010 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | |||||

| SS 310 | 0.015 | 2 | 0.015 | 0.020 | 0.015 | 24.00 26.00 | 0.10 | 19.00 21.00 | 54.7 | |||

| SS 310S | 0.08 | 2 | 1.00 | 0.045 | 0.030 | 24.00 26.00 | 0.75 | 19.00 21.00 | 53.095 | |||

| SS 310H | 0.04 0.10 | 2 | 1.00 | 0.045 | 0.030 | 24.00 26.00 | 19.00 21.00 | 53.885 | ||||

| 316 | Minimum | 16.0 | 2.03.0 | 10.0 | ||||||||

| Maximum | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316L | Minimum | 16.0 | 2.03.0 | 10.0 | ||||||||

| Maximum | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316TI | 0.08 | 10.00 14.00 | 2.0 | 0.045 | 0.030 | 16.00 18.00 | 0.75 | 2.00 3.00 | ||||

| 317 | 0.08 | 2 | 1 | 0.045 | 0.030 | 18.00 20.00 | 3.00 4.00 | 57.845 | ||||

| SS 317L | 0.035 | 2.0 | 1.0 | 0.045 | 0.030 | 18.00 20.00 | 3.00 4.00 | 11.00 15.00 | 57.89 | |||

| SS 321 | 0.08 | 2.0 | 1.0 | 0.045 | 0.030 | 17.00 19.00 | 9.00 12.00 | 0.10 | 5(C+N) 0.70 | |||

| SS 321H | 0.04 0.10 | 2.0 | 1.0 | 0.045 | 0.030 | 17.00 19.00 | 9.00 12.00 | 0.10 | 4(C+N) 0.70 | |||

| 347/ 347H | 0.08 | 2.0 | 1.0 | 0.045 | 0.030 | 17.00 20.00 | 9.0013.00 | |||||

| 410 | Minimum | 11.5 | ||||||||||

| Maximum | 0.15 | 1.0 | 1.00 | 0.040 | 0.030 | 13.5 | 0.75 | |||||

| 446 | Minimum | 23.0 | 0.10 | |||||||||

| Maximum | 0.2 | 1.5 | 0.75 | 0.040 | 0.030 | 30.0 | 0.50 | 0.25 | ||||

| 904L | Minimum | 19.0 | 4.00 | 23.00 | 0.10 | |||||||

| Maximum | 0.20 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 5.00 | 28.00 | 0.25 | |||

We are proud to be recognized as the leading stockist and distributor for high-temperature 316l Stainless Steel Heat Exchanger.

| Grade | Melting Point | Density | Yield Strength | Tensile Strength | Elongation |

|---|---|---|---|---|---|

| 304/ 304L | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 304H | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 40 % |

| 310 / 310S / 310H | 1402 °C (2555 °F) | 7.9 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 40 % |

| 306/ 316H | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 316L | 1399 °C (2550 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 317 | 1400 °C (2550 °F) | 7.9 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 321 | 1457 °C (2650 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 347 | 1454 °C (2650 °F) | 8.0 g/cm3 | Psi 30000 , MPa 205 | Psi 75000 , MPa 515 | 35 % |

| 904L | 1350 °C (2460 °F) | 7.95 g/cm3 | Psi 32000 , MPa 220 | Psi 71000 , MPa 490 | 35 % |

| Grade | Unified Numbering System | Werkstoff Nr. | European Standards | JIS Standards | GOST | British Standard | AFNOR |

|---|---|---|---|---|---|---|---|

| 304 | S30400 | 1.4301 | X5CrNi18-10 | SUS 304 | 08Х18Н10 | 304S31 | Z7CN18‐09 |

| 304L | S30403 | 1.4306 / 1.4307 | X2CrNi18-9 / X2CrNi19-11 | SUS 304L | 03Х18Н11 | 3304S11 | Z3CN18‐10 |

| 304H | S30409 | 1.4301 | |||||

| 310 | S31000 | 1.4841 | X15CrNi25-20 | SUS 310 | 20Ch25N20S2 | 310S24 | |

| 310S | S31008 | 1.4845 | X8CrNi25-21 | SUS 310S | 20Ch23N18 | 310S16 | |

| 310H | S31009 | ||||||

| 316 | S31600 | 1.4401 / 1.4436 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | SUS 316 | 316S31 / 316S33 | Z7CND17‐11‐02 | |

| 316L | S31603 | 1.4404 / 1.4435 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 | SUS 316L | 03Ch17N14M3 / 03Ch17N14M2 | 316S11 / 316S13 | Z3CND17‐11‐02 / Z3CND18‐14‐03 |

| 316H | S31609 | 1.4401 | |||||

| 316Ti | S31635 | 1.4571 | X6CrNiMoTi17-12-2 | SUS 316Ti | 08Ch17N13M2T | 320S31 | Z6CNDT17‐123 |

| 317 | S31700 | 1.4449 | SUS 317 | ||||

| 317L | S31703 | 1.4438 | X2CrNiMo18-15-4 | SUS 317L | |||

| 321 | S32100 | 1.4541 | X6CrNiTi18-10 | SUS 321 | |||

| 321H | S32109 | 1.4878 | X12CrNiTi18-9 | SUS 321H | |||

| 347 | S34700 | 1.4550 | X6CrNiNb18-10 | SUS 347 | 08Ch18N12B | ||

| 347H | S34709 | 1.4961 | X6CrNiNb18-12 | SUS 347H | |||

| 904L | N08904 | 1.4539 | X1NiCrMoCu25-20-5 | SUS 904L | STS 317J5L | 904S13 | Z2 NCDU 25-20 |

Exporter of 304 Stainless Steel Heat Exchanger with excellent pressure ratings, suitable for demanding applications in sectors like oil and gas, aerospace, and more

| Outer Diamewter | Specification | Tolerances | |||

|---|---|---|---|---|---|

| Outer Diameter | Wall Thickness | ||||

| Plus | Minus | Plus | Minus | ||

| Under 1.000 | ASTM-A-213 | .004 | .004 | 20% | 0% |

| 1.501 to 1.999 | Cold Finished Seamless | .008 | .008 | 22% | 0% |

| 4.001 to 5.000 | .015 | .025 | 22% | 0% | |

| 1.000 to 1.500 | ASME-SA-213 | .006 | .005 | 20% | 0% |

| 2.500 to 2.999 | Minimum Wall | .012 | .012 | 22% | 0% |

| 2.000 to 2.499 | Heat Exchanger Tube | .010 | .010 | 22% | 0% |

| 3.000 to 4.000 | .015 | .015 | 22% | 0% | |

Application of Stainless Heat Exchanger Tube

- Industrial machinery

- Textile industry

- Brewing equipment

- Construction and architecture

- Power generation