Are you looking for stainless steel 316 coiled tube supplier in India

Find a reliable 304 stainless steel coil tubing supplier offering a wide range of sizes to meet your specific project requirements

Table of content

| Standard | ASTM A213/ASME SA213, ASTM A269 /ASME SA 269, EN10216-5, JIS G3463 |

| Tolerance | D4/T4 |

| Strength | Burst, Tensile |

| END | Plain End |

| Soundness Tests | Ultrasonic, Eddy Current |

| Hardness | Micro, Rockwell |

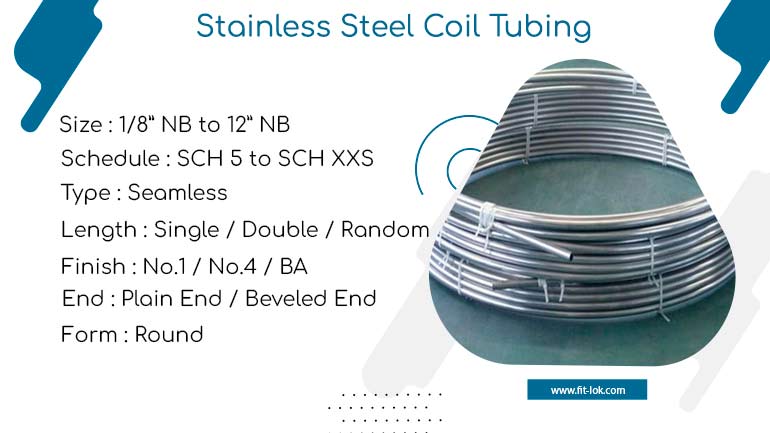

stainless steel coil tubing

ss tube coil

304 stainless steel coil tubing

316 Stainless steel Coiled Tube

SS 316 Welded Coil Tubing

Welded Stainless Steel Coil tube

The smooth internal surface of our SS 316 Welded Coil Tubing minimizes friction and ensures efficient fluid flow.

- Upgrading security

- lower your expenses

- a small container for storage and transportation

| Grade | Carbon | Magnesium | Phosphorus | sulfur | Silicon | Chromium | Nickel | Molybdenum |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | |

| 304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 |

| 316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

When it comes to sourcing high-temperature Welded Stainless Steel Coil tube, industry professionals trust our leading stockist and distributor services.

| Grade | Yield Strength | Temperure | Elongation | Tensile Strength | Heat |

|---|---|---|---|---|---|

| Ksi (MPa), Min. | Min. º F(º C) | Ksi (MPa), Min. | Treatment | ||

| TP304 | 30(205) | 1900 (1040) | 35 | 75(515) | Solution |

| TP304L | 25(170) | 1900 (1040) | 35 | 70(485) | Solution |

| TP316 | 30(205) | 1900(1040) | 35 | 75(515) | Solution |

| TP316L | 25(170) | 1900(1040) | 35 | 70(485) | Solution |

| Coil Tube Sizes | Thickness in MM | Diameter in MM | Weight in Kg/m |

|---|---|---|---|

| 6×1.0×6 | 2.0 | 27 | 1.04 |

| 6×1.0×2 | 2.0 | 20 | 0.60 |

| 6×1.0×4 | 2.0 | 24 | 0.82 |

| 6×1.0×5 | 2.0 | 25 | 0.90 |

| 6×1.0×1 | 1.0 | 8 | 0.15 |

| 6×1.0×7 | 2.0 | 27 | 1.15 |

| 6×1.0×3 | 2.0 | 21 | 0.75 |

| 6×1.0×8 | 2.2 | 32 | 1.40 |

| 8×1.0×1 | 1.0 | 10 | 0.28 |

| 8×1.0×2 | 1.8 | 24 | 0.89 |

Ensure the ss tube coil you select have the appropriate pressure rating to handle the desired fluid or gas pressures

| Outer Diameter | Size in Inch | Length | Wall Thickness |

|---|---|---|---|

| 0.250 | .250 X .065 W | 1,668 | 0.065 |

| 0.375 | .375 X .049 W | 1,225 | 0.049 |

| 0.375 | .375 X .065 W | 995 | 0.065 |

| 0.500 | .500 X .035 W | 1,232 | 0.035 |

| 0.500 | .500 X .049 W | 909 | 0.049 |

| 0.375 | .375 X .035 W | 1,685 | 0.035 |

| 0.500 | .500 X .049 W (15 Ra Max) | 909 | 0.049 |

| 0.125 | .125 X .035 W | 6,367 | 0.035 |

| 0.250 | .250 X .035 W | 2,665 | 0.035 |

| 0.500 | .500 X .065 W | 708 | 0.065 |

| 0.375 | .375 X .035 W (15 Ra Max) | 1,685 | 0.035 |

| 0.750 | .750 X .049 W | 584 | 0.049 |

| 0.250 | .250 X .035 W (15 Ra Max) | 2,665 | 0.035 |

| 0.750 | .750 X .065 W | 450 | 0.065 |

| 6mm | 6 MM X 1 MM W | 2,610 | 1mm |

| 0.250 | .250 X .049 W | 2,036 | 0.049 |

| 8mm | 8 MM X 1 MM W | 1,863 | 1mm |

| 10mm | 10 MM X 1 MM W | 1,449 | 1mm |

| 12mm | 12 MM X 1 MM W | 1,188 | 1mm |

Application of Soft SS Tubing

- HVAC systems

- Water treatment

- Marine applications

- Aerospace industry

- Automotive applications