Contact us if you are looking for ASTM A213 TP316l Tube supplier in India

We stock SA 213 Tp 316l ERW tube and 316L Stainless Steel ERW Tube in different sizes and wall thicknesses

What are the standard NDT (Non-Destructive Testing) methods used for Stainless steel 316l tube?

| Visual Inspection | To detect Surface defects |

|---|---|

| Hydrostatic Testing (as per ASTM A270, A249, or A269) | To check Leak and strength |

| Pneumatic Testing | Ulternative of hydrostatic testing |

| Dye Penetrant Testing | To find Surface cracks |

| Eddy Current Testing | To check Surface flaws |

| Ultrasonic Testing | To check Internal flaws |

| Radiographic Testing | To check internal weld issues |

| Helium Leak Testing | To find Ultra-small leaks |

Table of content

- Specification of Stainless Steel 316L Tube

- ASME SA 213 TP 316L Tube Price list

- Different types of ASTM A213 TP316L Tube

- Why buy ASTM A213 Grade 316L Tube from Fit-lok

- Size chart of SUS 316L Erw tubing

- UNS S31603 tubing dimensions

- SS 316l Schedule 10 Tube Tolerance chart

- Delivery condition of ASTM A213 Grade 316L Coiled Tube

- ASTM A213 TP 316L Superheater Tube Inspection and Testing

- Difference between 304 vs 316L SS tubes

- ASTM A213 TP316L Seamless Tube Heat resistance

- Heat treatment of ASTM A213 Type 316L Round Tube

- Stock list of Alloy 316L Tubing

- Which factors influence price of 316L Stainless Steel Tubing in India

- Applications of 316L SS Square Tube

- Stainless Steel 316L Welded Tubes chemical composition

- ASME SA 213 TP 316L Tube Mechanical properties

- AISI 316L welded tubing Physical properties

- ASTM A213 TP316L Equivalent

- Stock and Supply range of SA213 Type 316L Tubing

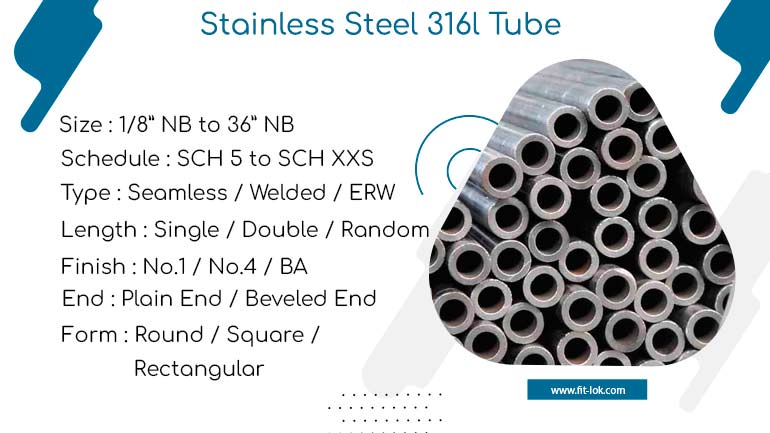

| Specification | ASTM A213/ ASME SA213 |

| Surfaces |

|

| Thickness Range | Schedule 5 to Schedule XXS |

| Standard length | 6 metres |

| Delivery Condition | Bright Annealed, MF, Annealed and Pickled, Polished, Cold Drawn |

| Surface Finish | No.8, BA, 320G, 400G, 500G, 2B, No.1, No.3, Mirror Polished, 800G Mirror finish, 8K, 2D, HL, No.4, 1D, 180G, 400G Satin/ Hairline, 600G |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Value Added Services |

|

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| END | Plain End, Beveled End |

| Technique | Cold rolled, Cold drawn, Hot rolled |

| Tolerance |

|

| Product | Price in USD | Price in Dirham | Price in Euro |

|---|---|---|---|

| 1.5 mm thick SS 316L Tube Bright Polished | US $14.15 per piece | 52.00 AED per piece | € 12.46 per piece |

| DN200 OD 219,08 mm x 3,76 mm 316L SS seamless tube Length | US $384.77 per piece | 1413.63 AED per piece | € 338.70 per piece |

| DIN 1.4404 tube OD 3 mm x 0,3 mm, Length – 100cm | US $20.41 per Kg | 75.00 AED per Kg | € 17.97 per Kg |

| DN10 OD 15 mm x 2,5 mm 316L Stainless steel seamless tube | US $37.38 per kg | 137.31 AED per Kg | € 32.90 per Kg |

SA 213 Tp 316l ERW tube

316L Stainless Steel ERW Tube

AISI 316L Welded Tube

316l Stainless Steel Square Tube

DIN 1.4404 Extruded Seamless Tube

UNS S31603 Round Tube

High Quality Materials

Manufacturing Capacity

Strong Export Network

Certifications and Compliance

| Inside Diameter | Wall Thickness | Outside Diameter (O.D.) / Wall |

|---|---|---|

| 0.062 | 0.0136 | 3/32″ x 0.016 |

| 0.038 | 0202 | 3/32″ x 0.028 |

| 0.042 | 0.0057 | 1/16″ x 0.010 |

| 0.054 | 0162 | 3/32″ x 0.020 |

| 0.030 | 0.0080 | 1/16″ x 0.016 |

| 0.022 | 0.0092 | 1/16″ x 0.020 |

| 1.01 | 0.0149 | 1/8″ x 0.012 |

| 105 | 0.0126 | 1/8″ x 0.010 |

| 0.069 | 0.0298 | 1/8″ x 0.028 |

| 0.093 | 0.0191 | 1/8″ x 0.016 |

| 0.055 | 0.0346 | 1/8″ x 0.035 |

| 085 | 0.0231 | 1/8″ x 0.020 |

We can provide AISI 316L Welded Tube and 316l Stainless Steel Square Tube in size range of 1/4″ to 4″

| NPS Designator | Schedule 10S in. | Schedule 40S in. | Schedule 80S in. | Schedule 160 in. | Schedule XX in. |

|---|---|---|---|---|---|

| 1/2 | 0.083 | 0.109 | 0.147 | 0.188 | 0.294 |

| 1/4 | 0.065 | 0.088 | 0.119 | ||

| 3/4 | 0.083 | 0.113 | 0.154 | 0.218 | 0.308 |

| 1 | 0.109 | 0.133 | 0.179 | 0.25 | 0.358 |

| 3/8 | 0.065 | 0.091 | 0.126 | ||

| 1 1/4 | 0.109 | 0.14 | 0.191 | 0.25 | 0.382 |

| 2 | 0.109 | 0.154 | 0.218 | 0.343 | 0.436 |

| 1 1/2 | 0.109 | 0.145 | 0.2 | 0.281 | 0.4 |

| 2 1/2 | 0.12 | 0.203 | 0.276 | 0.375 | 0.552 |

| 3 | 0.12 | 0.216 | 0.3 | 0.438 | 0.6 |

| 4 | 0.12 | 0.237 | 0.337 | 0.534 | 0.674 |

| 3 1/2 | 0.12 | 0.226 | 0.318 | 0.636 | |

| 5 | 0.134 | 0.258 | 0.375 | 0.625 | 0.75 |

| 8 | 0.148 | 0.322 | 0.5 | 0.906 | 0.875 |

| 6 | 0.134 | 0.28 | 0.432 | 0.719 | 0.864 |

| 10 | 0.165 | 0.365 | 0.5 | 1.125 | |

| 12 | 0.18 | 0.375 | 0.5 | 1.312 | |

| 16 | 0.188 | 0.375 | 0.5 | 1.594 | |

| 14 | 0.188 | 0.375 | 0.5 | 1.406 |

| Tolerances on D £ 219,1 mm | Tolerances on T | ||

|---|---|---|---|

| Tolerance class | Permissible deviation | Tolerance class | Permissible deviation |

| D3 | ± 0,75 % or ± 0,3 mm whichever is the greater | T3 | ± 10 % or ± 0,2 mm whichever is the greater |

| D4a | ± 0,5 % or ± 0,1 mm whichever is the greater | T4a | ± 7,5 % or ± 0,15 mm whichever is the greater |

The thickness range of DIN 1.4404 Extruded Seamless Tube and UNS S31603 Round Tube extends from Schedule 5 to Schedule XXS.

| Delivery condition | Surface condition |

|---|---|

| HFD (Hot finished heat treated) | Metallically clean |

| CFA (Cold finished bright annealed) | Metallically bright |

| CFP (Cold finished heat treated) | Metallically bright polished |

- Dimensional Inspection

- Tensile Testing

- Chemical Composition Testing

- Hardness Testing

- Hydrostatic Pressure Testing

- Eddy Current Testing

- Ultrasonic Testing

- Crevice Corrosion Testing

- Impact Testing

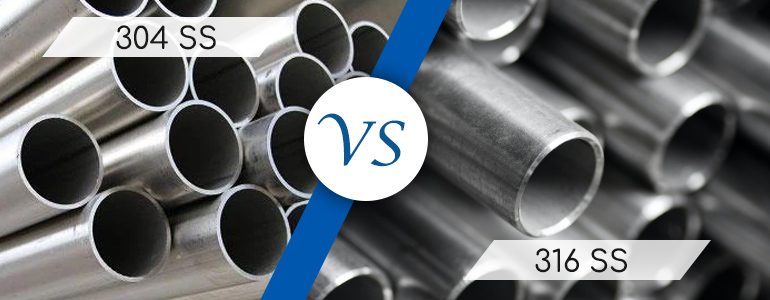

| Property | 304 stainless steel | 316 stainless steel |

|---|---|---|

| Composition | It contains 18% chromium and 8% nickel | It contains 16% chromium and 10% nickel |

| Molybdenum Content | It does not have Molybdenum | Contains upto 2-3% Molybdenum |

| Weldability | Good weldability | Excellent weldability |

| Corrosion Resistance | Good resistance | Superior corrosion resistance |

| Cost | Less expensive | More expensive due to Mo content |

Exporter of SS 316L Annealed Tube in more than 20 countries, SA213 TP316L Polished Tube is available in cut to length sizes

| Heat Resistance | 425-860 °C |

|---|

| Heat Treatment | 1010-1120 °C and cool rapidly |

|---|

| 316L SS Tubing | Stainless Steel 316L Fabricated Tube |

| ASME SA249 TP 316L 12mm Tube | 316L SS Seamless Tubing |

| ASTM A249 TP 316L High Pressure Tube | SS A249 TP316L Thin Wall Tubing |

| Stainless Steel 1.4404 Electropolished Tubes | 316L SS Cold Drawn Seamless Tube |

| Stainless Steel 316L Hydraulic Tubing | SS A249 TP316L Coiled Tube |

| UNS S316L03 ERW Tube | ASTM A249 TP 316L Electropolished Tube |

| ASME SA249 TP 316L Rectangular Tubing | Stainless Steel 1.4404 CDW Tube |

| 316L SS Electropolish Tube | 316L Stainless Steel Capillary Tubing |

| ASTM A249 TP 316L Small Diameter Tubing | UNS S316L03 ERW Tubing |

| Raw Material Costs | Price of Nickel and Molybdenum can fluctuate due to supply and demand |

|---|---|

| Production Costs | Sizes, Finish, Wall thickness and Manufacturing process all play important role on pricing |

| Market Demand | If market demand is high prices will go up |

| Logistics Costs | Shipping costs varies based on different locations and get add into final amount |

| Quality Control | In house and third party inspection increase cost of manufacturing |

| Global Trade and Tariffs | Various taxes and tarriffs from India increases cost of the product |

| Order Volume | If order size is small pricing will be comparatively higher |

Chemical industry

Petrochemical

Marine industry

Oil and Gas Industry

Food processing

Power Generation

Structural Applications

Automotive Industry

| Grade | C | Ni | Si | Mn | P | S | Mo | Cr | Fe |

|---|---|---|---|---|---|---|---|---|---|

| A213 TP316 | 0.08 max | 11.00 – 14.00 | 1.0 max | 2.0 max | 0.045 max | 0.030 max | 2.00 – 3.00 | 16.00 – 18.00 | 67.845 min |

| Yield Strength (0.2%Offset) | Elongation | Melting Point | Density | Tensile Strength |

|---|---|---|---|---|

| Psi – 30000 , MPa – 205 | 0.35 | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi – 75000 , MPa – 515 |

| Elec Resistivity (nΩ.m) | Elastic Modulus (GPa) | Thermal Conductivity (W/m.K) | Mean Co-eff of Thermal Expansion (µm/m/°C) | Specific Heat 0-100 °C (J/kg.K) | |||

|---|---|---|---|---|---|---|---|

| At 100 °C | At 500 °C | 0-100 °C | 0-315 °C | 0-538 °C | |||

| 740 | 193 | 16.3 | 21.5 | 15.9 | 16.2 | 17.5 | 500 |

| STANDARD | EN | UNS | BS | JIS | WERKSTOFF NR. | AFNOR |

|---|---|---|---|---|---|---|

| SS 316 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | S31600 | 316S31 / 316S33 | SUS 316 | 1.4401 / 1.4436 | Z7CND17-11-02 |

| Types | Outside Diameter Range (MM) | Wall Thickness (MM) |

|---|---|---|

| Round Tube | 1mm to 12mm | 0.5 mm to 5mm |

| Square Tube | 12.7 mm * 12.7 mm to 254 mm * 254 mm | 0.9 mm to 6.35 mm |

| Ornamental Tubes | 2.7mm to 72mm | 0.5mm-2.0mm |

| U Shaped Tube | 20mm to 200mm | 0.5mm-2.0mm |

| Capillary Tube | 0.28mm to 10mm | 0.08mm – 1.2mm |