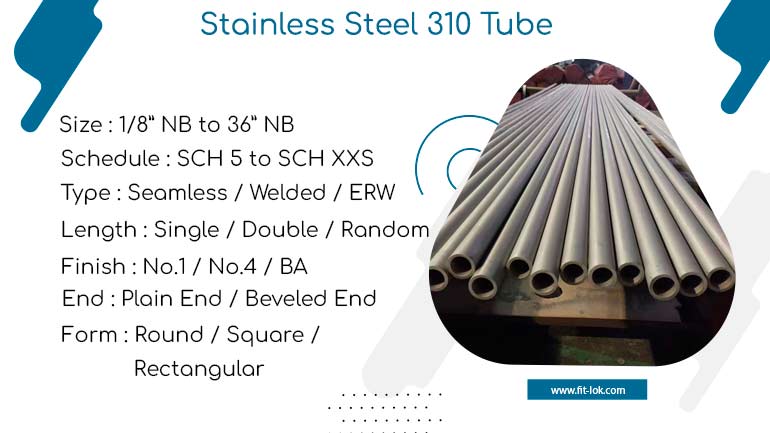

ASTM A213 TP310 Tube supplier in India

Hot rolled 310 Stainless Steel Square Tubing and SA 213 Tp 310 welded Tube exhibits excellent mechanical strength and durability.

310 Stainless Steel Tubing Specification

| Specification |

ASTM A213/ ASME SA213 |

| Surfaces |

- Average roughness value: Ra < 0.8 µm

- Weld seam area: Ra < 1.6 µm

|

| Standard length |

6 metres |

| Delivery Condition |

MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range |

Schedule 5 to Schedule XXS |

| Manufacturing Type |

CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish |

BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

- Cutting

- Destructive and Non Destructive

- Threading

- Polishing (Electro & Commercial)

- Draw & Expansion as per required Size & Length

- Annealed & Pickled Bending

- Beveling

- Ultrasonic Testing

|

| END |

Plain End, Beveled End, Treaded Tubes |

| Processing Service |

Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique |

Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

- Outer Diameter: +/- 0.2mm

- Thickness: +/- 10% OR as customer request

- Length: +/- 10mm

|

UNS S31000 seamless Tube Sizes

| Size range |

Wall thickness |

| 0.30 mm OD up to 60 mm OD |

0.10 mm up to 6 mm |

We offer Aisi 310 Square Tubing and Alloy 310 ERW Tube that is cut to length in any size

Stainless Steel 310 Tube Price List

| Product |

Price in USD

(Kg) |

Price in Dirham

(Kg) |

Price in Euro

(Kg) |

| 3.25 MM Dia AISI 310 Seamless Tube |

US $1.89 |

6.94 AED |

€ 1.63 |

| 12.7MM X 1.20 MM X 6100 MM SS 310 Tubing |

US $2.16 |

7.93 AED |

€ 1.86 |

ASME SA 213 TP 310 Tube Chemical Composition

| Carbon |

Sulphur |

Silicon |

Manganese |

Phosphorus |

Nickel |

Chromium |

| 0.25 max |

0.030 max |

1.50 max |

2.00 max |

0.045 max |

19.00 – 22.00 |

24.00 – 26.00 |

Stainless Steel Type 310 Round Tube and DIN 1.4841 Cold Drawn Tube are often used in heat exchangers, condensers, furnace components

AISI 310 Welded Tubes Physical Properties

| Density |

Specific heat capacity |

Thermal conductivity |

Electrical resistivity |

Modulus of Elasticity |

| 7.9 g/cm³ |

500 J/kg K |

15 W/m K |

0.85 Ω mm²/m |

200 Gpa |

DIN 1.4845 Round Tubes Mechanical Properties

| Tensile Strength |

Proof Stress |

Elongation |

Hardness |

| 520 Mpa |

205 Mpa |

40% |

225 HV |

SS 310 boiler tubes Equivalent

| Grade |

UNS |

DIN |

JIS |

| 310 |

S31000 |

1.4841 |

SUS 310 |

Choose the perfect UNS S31000 Annealed Tube and 310 Stainless Steel Exhaust Tubing dimensions and sizes for your project requirements

| Stainless Steel 310S Pipe |

4 inch 310H Stainless Steel Seamless Pipe |

| 310H Stainless Steel Pipes |

ASME SA312 TP 310S Welded Pipes |

| SS A312 TP310H Seamless Steel Pipe |

ASTM A312 TP 310H Cold Drawn Welded Pipes |

| 310H Stainless Steel Welded Pipe |

UNS S31000 Cold Drawn Pipes |

| ASME SA312 TP 310S ERW Pipe |

Schedule 5S Stainless Steel 1.4841 Seamless Pipes |

| UNS S31000 EFW Pipe |

Schedule 40 310S SS Pipe |

| Stainless Steel 1.4841 Cold Drawn Seamless Pipes |

ASME SA312 TP 310S Precision Pipe |

| Stainless Steel 310S Seamless Steel Precision Pipe |

High pressure SS A312 TP310H Pipe |

| 310S SS Cold Drawn Seamless Pipes |

Stainless Steel 1.4841 Electropolished Pipe |

| ASME SA312 TP 310S Custom Pipe |

Stainless Steel 310S Cold Drawn Pipes |

ASTM A213 310 Tube Dimensions

| Sizes in Inch |

Outside Diamter (MM) |

Wall Thickness |

Schedule |

Kg/m |

| 1/4″ |

13.72 |

1.65 |

10S |

0.5 |

| 1/2″ |

21.34 |

2.11 |

10S |

1.02 |

| 1/2″ |

21.34 |

2.77 |

40S |

1.29 |

| 3/4″ |

26.67 |

2.11 |

10S |

1.3 |

| 1″ |

33.4 |

6.352 |

160 |

4.3 |

| 1¼” |

42.16 |

6.352 |

160 |

5.69 |

| 1½” |

48.26 |

5.08 |

80S |

5.49 |

| 2″ |

60.33 |

2.77 |

10S |

3.99 |

| 2½” |

73.03 |

3.05 |

10S |

5.35 |

| 3″ |

88.9 |

11.132 |

160 |

21.67 |

| 5″ |

141.3 |

15.882 |

160 |

49.87 |

| 3/8″ |

17.15 |

1.65 |

10S |

0.64 |

| 3½” |

101.6 |

8.08 |

80S |

18.92 |

| 6″ |

168.28 |

18.262 |

160 |

68.59 |

| 8″ |

219.08 |

23.012 |

160 |

112.97 |

| 8″ |

219.08 |

18.23 |

120 |

91.3 |

Creep Rupture Properties of SS 310 seamless tubes

| Temperature, °F |

100,000 Hour Rupture Strength, ksi |

Minimum Creep 0.0001%/hr, ksi |

| 12000 |

14.4 |

14.9 |

| 1400 |

4.5 |

3.3 |

| 1600 |

1.5 |

1.1 |

| 1800 |

0.66 |

0.28 |

HSN Code of Alloy 310 Instrumentation Tubing

310 SS Boiler Tube Features