Top Notch Alloy 254 Manifold Solenoid Valve Manufacturer in India

Refer Weight Chart and Price list of UNS S31254 Manifold Heat Control Valve

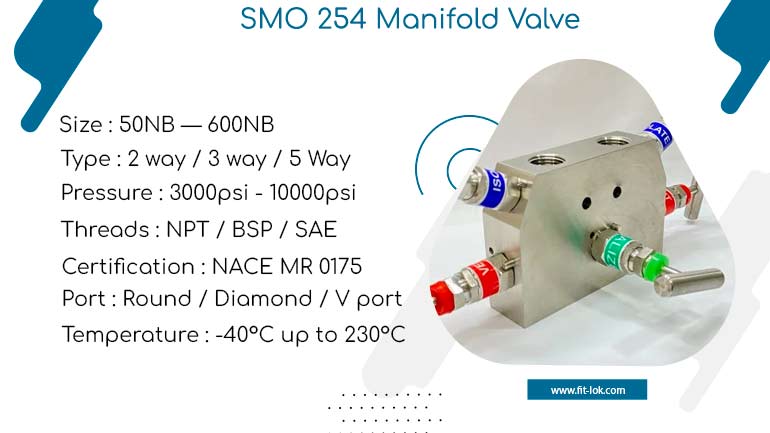

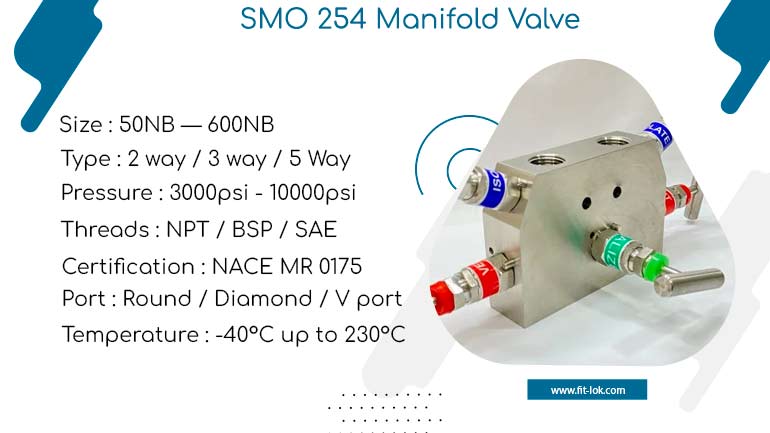

SMO 254 manifold valve specification

| Type |

2 Way / 3 Way / 5 Way |

| Pressure Rating |

Up to 6000 psi |

| Port Size |

1/4″ – 1/2″ |

| Threads |

BSP / NPT / SAE |

| End Connections |

Flanged / NPT (female/male) / Compression tube end |

| Sealing |

PTFE / Graphite / PEEK |

| Origin |

- American

- European

- Janpanese

- Korean

|

| Surface Finish |

Electropolished / Passivated |

| Compliance |

NACE MR0175 / ANSI B31.1 / ISO 15156 |

| Temperature Rating |

up to 1,200 °F |

Alloy 254 manifold control valve chemical composition

| SMO 254 |

C |

Ni |

Cr |

Mn |

Mo |

Fe |

Si |

S |

Cu |

P |

| 0.002 maximum |

17.05 to 18.05 |

19.05 to 20.05 |

1 maximum |

6 to 6.05 |

to |

0.08 maximum |

0.001 maximum |

0.05 to 1 |

0.003 maximum |

SMO 254 manifold tuning valve Mechanical properties

| Melting Point |

Density |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| 1320 to 1390 ℃ |

8.0 g/cm3 |

650 |

300 |

35 % |

Equivalent grade of SMO 254 manifold valves

| STANDARD |

WNR |

UNS |

EN |

AFNOR |

| SMO 254 |

1.4547 |

S31254 |

X1CrNiMoCuN20-18-7 |

Z1 CNDU 20.18.06Az |

Pressure Rating Of DIN 1.4547 manifold valve

| Operating pressure |

Max.: 700 bar (10,153 psi) |

Size Chart of 6 Moly Alloy needle valve manifold check valve

| Connections |

C |

End Connection |

LG |

THK |

Top/Bottom Connection |

Width |

| 4 |

1.38 |

HF9 |

5.26 |

1.5 |

HF6 |

2.63 |

| 6 |

1.38 |

HF9 |

7.76 |

1.5 |

HF6 |

2.63 |

| 8 |

1.38 |

HF9 |

10.26 |

1.5 |

HF6 |

2.63 |

| 10 |

1.38 |

HF9 |

12.76 |

1.5 |

HF6 |

2.63 |

| 14 |

1.38 |

HF9 |

17.76 |

1.5 |

HF6 |

2.63 |

SMO 254 Manifold Valve Physical properties

| Density |

Modulus of elasticity |

Shear modulus |

Poisson’s ratio |

| 8 g/cm3 |

195 GPa |

75 GPa |

0.3 |

Annealing and Hot Working of UNS S31254 Hydraulic Manifold Valve

| Annealing |

1149-1204°C |

| Hot Working |

982 – 1149°C |

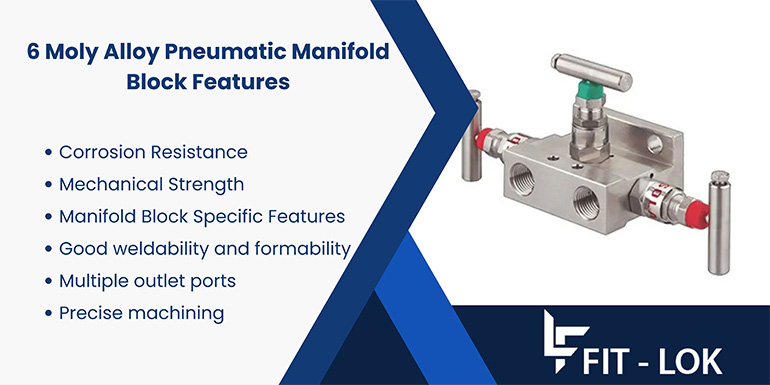

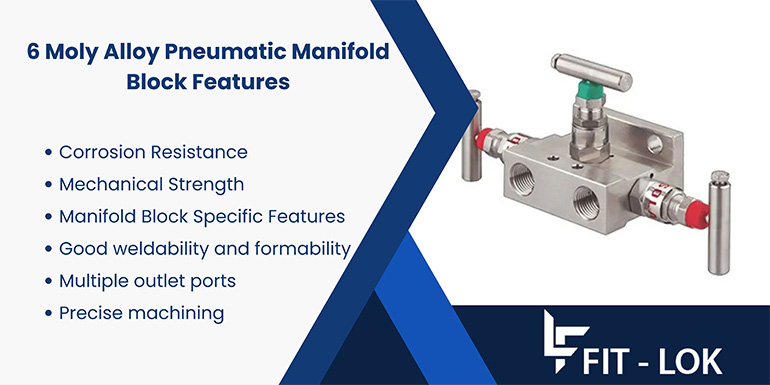

6 moly alloy Pneumatic Manifold Block features

Test Pressure of 1.4547 steel Manifold Control Valve

| Hydrostatic |

Body – 620 Kg/cm2

Seat – 413 Kg/cm2 |

| Pneumatic |

Seat – 40 Kg/cm2 |

Alloy 254 Instrument Manifold Valve material testing

- Mill Test Certificate

- Heat Treatment

- Non Destructive Testing

- Leak Testing

- Operational Tests

- Traceability

- Documentation

254 SMO 3 Way Manifold Valve Application

- Petrochemical Industry

- Oil & Gas

- Pharmaceutical

- Desalination Plants

- Food Processing

- Chemical Industry