Buy directly from Alloy 254 Spring Check Valve Manufacturer in India

View dimension and pressure rating of 254 SMO Poppet Check Valve

Table of content

- SMO 254 Check Valve Specification

- Alloy 254 instrumentation check valve types

- Price list of UNS S31254 Check Valve

- Alloy 254 SMO Poppet Check Valve chemical composition

- UNS S31254 inline Check Valves mechanical properties

- DIN 1.4547 Spring Check Valve equivalent grade

- Material of construction of DIN 1.4547 Spring Check Valve

- Pressure temperature rating of 254 SMO Hydraulic Check Valves

- WNR 1.4547 Check Valves Dimensions

- 6 Moly Alloy control check valve applications

- 254 Smo Instrumentation check valve benefits

- DIN 1.4547 Check Valve Testing requirements

We keep ready stock of DIN 1.4547 Spring Check Valve in size range of 1/2″ to 2″

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

SMO 254 Hydraulic Check Valve

Alloy 254 Inline Check Valve

UNS S31254 Nrv Valve

Alloy 254 SMO Instrument Air Check Valve

DIN 1.4547 Non Return Valve

254 SMO Spring Check Valve

ASTM A182 254 SMO Instrumentation Check Valve

A351 CK3MCuN Poppet Check Valve

Alloy 254 SMO Instrument Control Valve

Price of Alloy 254 SMO Poppet Check Valve depends on several factors such as pressure rating, sizes, design type and grades. It normally range between 15$ to 80$ per piece. For updated price list of ASTM A182 254 SMO Instrumentation Check Valve contact us at sales@fit-lok.com

Supplier and stockist of UNS S31254 Piston Check Valve in Mumbai

| Grade | % | Ni | Mo | Cr | Cu | C | N | P | Mn | Si | S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SMO 254 | Min. | 17.5 | 6 | 19.5 | 0.5 | 0.18 | |||||

| Max. | 18.5 | 6.5 | 20.5 | 1 | 0.02 | 0.22 | 0.03 | 1 | 0.8 | 0.01 |

| Element | Yield Strength (0.2%Offset) | Elongation | Melting Point | Density | Tensile Strength |

| SMO 254 | 300 | 35 % | 1320-1390 ℃ | 8.0 g/cm3 | 650 |

| STANDARD | WERKSTOFF NR. | AFNOR | SIS | UNS | EN |

|---|---|---|---|---|---|

| SMO 254 | 1.4547 | Z1 CNDU 20.18.06Az | 2378 | S31254 | X1CrNiMoCuN20-18-7 |

| Component | Material Grade/ ASTM Specification |

| Inlet body | 6-Moly/B691 |

| Poppet | Fluorocarbon FKM-bonded alloy C-276/B574 |

| Spring | Alloy X-750 /AMS 5699 |

| Poppet stop | Alloy C-276/B575 |

| Backup ring | PTFE/D1710 |

| O-ring | Fluorocarbon FKM |

| Outlet body | 6-Moly/B691 |

| Lubricant | PTFE-based |

| Material | SMO 254 |

| Temperature, °F (°C) | Working Pressure, psig (bar) |

| –10 (–23) to 100 (37) | 6000 (413) |

| 200 (93) | 5800 (399) |

| 250 (121) | 5500 (378) |

| 300 (148) | 5200 (358) |

| 350 (176) | 5000 (344) |

| 400 (204) | 4800 (330) |

| End Connections | Pressure Rating at 100°F (37°C) psig (bar) |

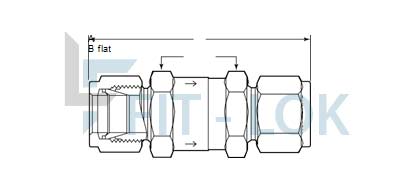

Cv | Dimensions in. (mm) |

||

| Type | Size in. | SMO 254 | A | B | |

| Fractional tube fitting | 1/4 | 5000 (344) | 0.67 | 2.43 (61.7) | 11/16 |

| 3/8 | 6000 (413) | 1.8 | 2.75 (69.9) | 1 1/16 | |

| 1/2 | 2.96 (75.2) | ||||

| 3/4 | 5000 (344) | 4.7 | 3.52 (89.4) | 1 5/8 | |

| 1 | 4500 (310) | 3.88 (98.6) | |||

| Female NPT | 1/4 | 5000 (344) | 0.67 | 2.13 (54.1) | 11/16 |

| 3/8 | 5300 (365) | 1.8 | 2.55 (64.8) | 1 1/16 | |

| 1/2 | 4900 (337) | 3.03 (77.0) | |||

| 3/4 | 4600 (316) | 4.7 | 3.23 (82.0) | 1 5/8 | |

| 1 | 4400 (303) | 3.83 (97.3) | |||

| Male NPT | 1/4 | 5000 (344) | 0.67 | 2.17 (55.1) | 11/16 |

| 3/8 | 6000 (413) | 1.8 | 2.36 (59.9) | 1 1/16 | |

| 1/2 | 2.73 (69.3) | ||||

| 3/4 | 5000 (344) | 4.7 | 3.29 (83.6) | 1 5/8 | |

| 1 | 3.67 (93.2) | ||||

UNS S31254 inline Check Valves are widely used in marine environment

- Marine Applications

- Oil & Gas Industry

- Food and Beverage Industry

- Water Treatment Plants

- Pulp and Paper Industry

- Power Generation

- Refineries

- Chemical Processing

- Prevents Backflow

- Compatibility with Aggressive Chemicals

- Long Service Life

- Resistance to Chlorides

- Easy to Weld and Fabricate

- Ability to Withstand High Temperatures

- High Strength

- Seat Tightness Test

- Corrosion Resistance Testing

- Functional Testing

- Hydrostatic Pressure Testing

- Leakage Testing

- Vibration Testing

- Hardness Testing

- Visual Inspection

- Backflow Testing