One of the biggest Alloy 825 Condenser Tube supplier in India

Alloy 825 Welded Tubing and Inconel 825 Cold Rolled Coiled Tube can be used at cryogenic temperatures

Table of content

- Incoloy 825 Tube Specification

- Alloy 825 Tube Types

- Incoloy 825 tube price

- Alloy 825 Welded Tubing Size Range

- Nickel 825 Capillary Tubing Dimension

- Wall Thickness of ASME SB 163 UNS N08825 Tube

- Alloy 825 Redrawn Tube Dimensional tolerance

- Incoloy 825 Tubing Manufacturing Standards

- Features of Alloy 825 Seamless Tube

- SB 163 UNS N08825 Tubes Trade names

- PREN value of 2.4858 Inconel 825 Condenser Tube

- Alloy 825 Welded Tube Operating temperature

- Inspection of Nickel 825 Exhaust Tubing

- Heat Treatment of Incoloy 825 Straight Tubing

- UNS N08825 Welded Tube Chemical Composition

- Inconel 825 Electropolish Tube Mechanical Properties

- Incoloy 825 tube equivalent

- ASTM B163 UNS N08825 Welded Tube physical properties

- Welding material of 825 Incoloy Round Tubing

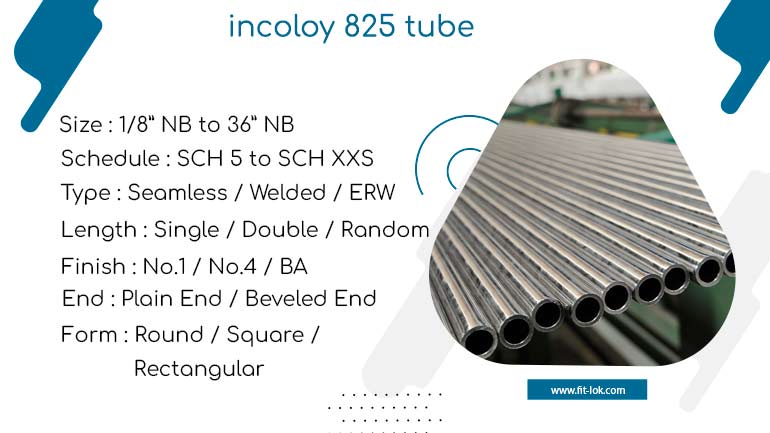

| Specification | ASTM B163 / ASME SB163 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

Alloy 825 Welded Tubing

Inconel 825 Cold Rolled Coiled Tube

825 Inconel Bright Annealed Tube

Inconel 825 Electropolish Tube

NCF 825 Rectangular Tubing

ASTM B423 Incoloy 825 Exhaust Tubing

| Product | Price in USD (Kg) |

Price in Dirham (Kg) |

Price in Euro (Kg) |

|---|---|---|---|

| Incoloy 825 Seamless Tube, 1″, 6MTR | US $12.59 | 46.24 AED | € 10.87 |

| 3/4 X SCH.10 Alloy 825 Tubing | US $11.95 | 43.89 AED | € 10.32 |

Reach out to us today to receive a price that is both fair and reasonable for high UNS N08825 Welded Tube and ASTM B423 Alloy 825 Seamless Tubing.

| BWG | mm | in |

|---|---|---|

| 1 | 7.62 | 0.3 |

| 2 | 7.21 | 0.283 |

| 3 | 6.58 | 0.259 |

| 4 | 6.05 | 0.238 |

| 5 | 5.59 | 0.22 |

| 6 | 5.16 | 0.203 |

| 7 | 4.57 | 0.179 |

| 8 | 4.19 | 0.164 |

| 9 | 3.76 | 0.147 |

| 10 | 3.4 | 0.134 |

| 11 | 3.05 | 0.12 |

| 12 | 2.77 | 0.109 |

| 13 | 2.41 | 0.095 |

| 14 | 2.11 | 0.083 |

We provide NCF 825 Rectangular Tubing and ASTM B423 Incoloy 825 Exhaust Tubing with superior mechanical properties, ensuring long-term structural integrity.

| Gauge | Outside Diameter Tolerance mm | Regular Wall (RW) mm | Thin Wall (TW) mm | Ultra Thin Wall (UTW) mm | Extra Thin Wall (XTW) mm |

|---|---|---|---|---|---|

| 30 | 0.304 – 0.317 | 0.064 – 0.089 | |||

| 29 | o.330 – 0.342 | 0.064 – 0.089 | |||

| 28 | 0.355 – 0.368 | 0.076 – 0.102 | |||

| 27 | 0.406 – 0.419 | 0.089 – 0.115 | 0.064 – 0.089 | ||

| 26 | 0.457 – 0.469 | 0.089 – 0.114 | |||

| 25 | 0.508 – 0.520 | 0.115 – 0.140 | 0.089 – 0.114 | ||

| 24 | 0.558 – 0.571 | 0.114 – 0.140 | 0.089 – 0.114 | 0.051 – 0.102 | |

| 23 | 0.635 – 0.647 | 0.140 – 0.165 | 0.089 – 0.114 | 0.051 – 0.102 | |

| 22 | 0.711 – 0.723 | 0.140 – 0.165 | 0.096 – 0.121 | 0.051 – 0.102 | 0.077 – 0.102 |

| Types of Incoloy 825 Tube | Wall thickness | Out diameter (OD) |

|---|---|---|

| NB Sizes (in stock) | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | 1/8″ ~ 8″ |

| Incoloy 825 Seamless Tube | As per requirement | 5.0mm ~ 203.2mm |

| Incoloy 825 Welded Tube | 1.0 ~ 15.0 mm | 5.0mm ~ 1219.2mm |

Exporter of ASTM B705 Incoloy 825 High Pressure Tubing and Nickel Alloy 825 Capillary Tubing, ensuring seamless installation and significant labor cost reduction

| OD | OD Tolerance | Wall Tolerance |

|---|---|---|

| .250″ – .500″ excl | +.004″/-.000″ | ± 10% |

| .500″–.750″ incl | +.005″/-.000″ | ± 10% |

| Standard | Type |

|---|---|

| ASTM B444 | Welded Tubes |

| ASTM B626 | Seamless Tubes |

| UNS: | N08825 |

| international Specifications: | ISO 6207, DIN 17751, VdTüV 432 |

| Specifications: | ASTM B423, ASTM B829, ASTM B423, ASTM B705, ASTM B704, ASTM B775, ASTM B751 |

| PREN value | 30 |

|---|

| Operating temperature | -196°C to 427°C |

|---|

- Visual Inspection

- Hydrostatic Test

- Eddy Current Testing

- Ultrasonic Testing

- Radiographic Test

- PMI Testing

- Dye Penetrant Test

| Heat Treatment | 940°C |

|---|

| Grade | Ni | Mn | C | Si | Cu | S | Fe | Al | Cr | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| 825 | 38.00 – 46.00 | 1.00 max | 0.05 max | 0.5 max | 1.50 – 3.00 | 0.03 max | 22.00 min | 0.02 max | 19.50 – 23.50 | 0.06 – 1.20 |

| Tensile Strength | Proof Stress | Elongation |

|---|---|---|

| 770 Mpa | 440 Mpa | 35% |

| STANDARD | UNS | WNR | BS | JIS | AFNOR | GOST | OR | EN |

|---|---|---|---|---|---|---|---|---|

| Incoloy 825 | N08825 | 2.4858 | NA 16 | NCF 825 | NFE30C20DUM | ЭП703 | Xh28BT | NiCr21Mo |

| Density | Specific heat capacity | Melting temperature | Electrical resistivity | Curie temperature |

|---|---|---|---|---|

| 8.14 g/cm3 | 440 J/(kg*K) | 1370-1400 °C | 1127 μΩ*m | -196 °C |

- Gas Tungsten Arc Welding

- Shielded Metal Arc Welding

- Gas Metal Arc Welding

- Orbital Welding