UNS N08800 seamless tube supplier in India

Can Incoloy 800 tube be used in sulfuric acid environments?

Yes, It offers very good resistance in sulfuric acid environments. But performance of these tubes heavily depends on acid concentration, temperature, and presence of impurities like chlorides. We offers MTC with 100% Traceability for our Alloy 800h seamless tube. We are reliable Incoloy 800 Tube Manufacturer in India in size range of 1/2″ to 4″.

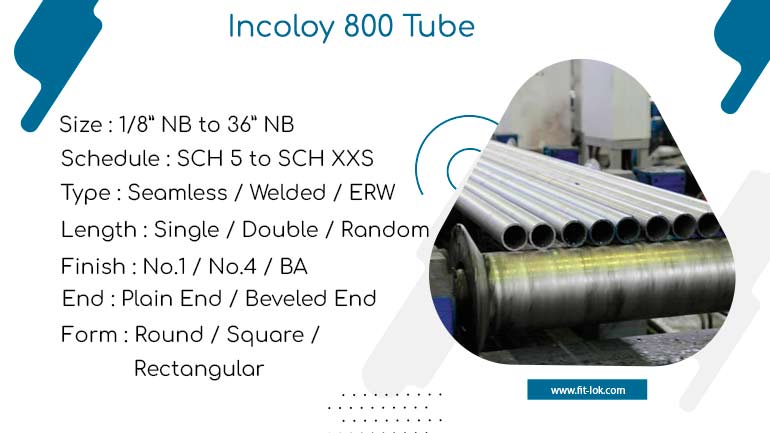

View specification of Nickel Alloy 800 Tubing and Price list of 1.4876 Incoloy Heat exchanger Tube

Table of content

- Incoloy 800 Tube Specification

- UNS N08800 seamless tube Types

- Incoloy 800 tube price

- Why buy ASME SB 163 UNS N08800 Tube from Fit-lok?

- Difference between Incoloy 800 Vs 800H Tube

- Max temperature range of Incoloy 800 Seamless Tube

- ASTM B163 UNS N08800 Tube Dimension

- Alloy 800HT Tube Pressure Rating

- Gauge Thickness of Incoloy 800H Tube

- Incoloy 800 tube size chart

- Tolerances of 1.4876 Incoloy Tube

- Manufacturing standards of UNS N08800 Hydraulic Tubing

- Nickel Alloy 800 Capillary Tube Surface finish

- Applications of Alloy 800 Welded Tubing

- Alloy 800 extruded Tubing tensile properties

- Modulus of Elasticity of Incoloy N08800 Exhaust Tubing

- Nickel Alloy 800 Tubing Chemical Composition

- DIN 1.4876 Heat exchanger Tube Mechanical Properties

- Incoloy 800 tube equivalent

- ASTM B163 UNS N08800 Tubing Physical properties

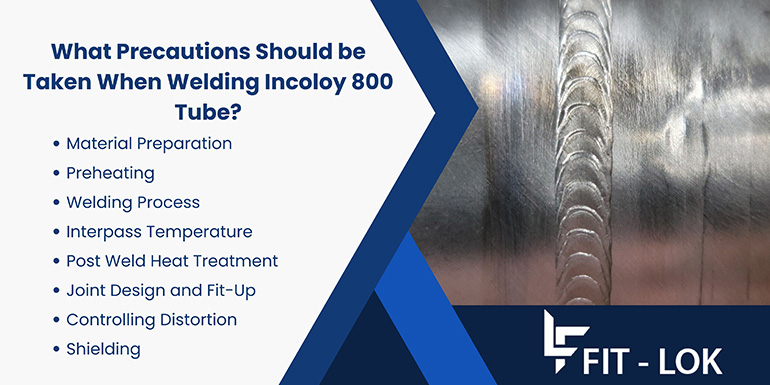

- What precautions should be taken when welding Incoloy 800 Tube?

| Specification | ASTM B163 / ASME SB163 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

Alloy 800 Welded Tubing

ASTM B163 UNS N08800 Tube

W. Nr. 1.4876 Tubes

Inconel Alloy 800 Tube

Alloy 800 Extruded Seamless Tube

UNS N08800 Hydraulic Tubing

| Product | Price in USD (Kg) |

Price in Dirham (Kg) |

Price in Euro (Kg) |

|---|---|---|---|

| 12.7MM OD X 0.7MM WALL Incoloy 800 Welded Tube | US $14.20 | 52.15 AED | € 12.21 |

| 9.53MM OD X 0.6MM WALL Alloy 800 Welded Tube | US $15.58 | 57.22 AED | € 13.40 |

Refer temperature range of UNS N08800 Capillary Tubing, We stock Incoloy 800 Coiled Tubing which offers long term durability

| Feature | Incoloy 800 | Incoloy 800H |

|---|---|---|

| Heat Treatment | As-rolled or annealed | Solution annealed |

| Maximum Service Temperature | 816 °C | 870 °C |

| Creep Resistance | Lower | Improved |

| Fabrication | Easier to weld | Requires controlled welding |

| Cost | Generally lower | Slightly higher |

| Max Temperature Range | 816 °C |

|---|

View sizes and dimensions of Alloy 800 Tube and Nickel 800 Seamless Tube.

| B.W.G | Wall | 2 | 1.75 | 1.5 | 1.25 | 1 | 0.875 | 0.75 | 0.625 | 0.5 |

|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | ||||||||||

| 10 | 0.134 | 1.732 | 1.482 | 1.232 | 0.982 | 0.732 | 0.607 | 0.482 | 0.357 | 0.232 |

| 11 | 0.12 | 1.76 | 1.51 | 1.26 | 1.01 | 0.76 | 0.635 | 0.51 | 0.385 | 0.26 |

| 12 | 0.109 | 1.782 | 1.532 | 1.282 | 1.032 | 0.782 | 0.657 | 0.532 | 0.407 | 0.282 |

| 13 | 0.095 | 1.81 | 1.56 | 1.31 | 1.06 | 0.81 | 0.685 | 0.56 | 0.435 | 0.31 |

| 14 | 0.083 | 1.834 | 1.584 | 1.334 | 1.084 | 0.834 | 0.709 | 0.584 | 0.459 | 0.334 |

| 15 | 0.072 | 1.856 | 1.606 | 1.356 | 1.106 | 0.856 | 0.731 | 0.606 | 0.481 | 0.356 |

| 16 | 0.065 | 1.87 | 1.634 | 1.37 | 1.12 | 0.87 | 0.745 | 0.62 | 0.495 | 0.37 |

| 17 | 0.058 | 1.884 | 1.652 | 1.384 | 1.134 | 0.884 | 0.759 | 0.634 | 0.509 | 0.384 |

| 18 | 0.049 | 1.902 | 1.666 | 1.402 | 1.152 | 0.902 | 0.777 | 0.652 | 0.527 | 0.402 |

| 19 | 0.042 | 1.916 | 1.68 | 1.416 | 1.166 | 0.916 | 0.791 | 0.666 | 0.541 | 0.416 |

| 20 | 0.035 | 1.93 | 1.686 | 1.43 | 1.18 | 0.93 | 0.805 | 0.68 | 0.555 | 0.43 |

| Tube O.D. (in.) |

Wall Thickness of Tube (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

| GAUGE | TYPICAL VALUE (INCH) | THICKNESS RANGE (INCH) |

|---|---|---|

| 22 | 0.028 | 0.025 – 0.029 |

| 20 | 0.035 | 0.031 – 0.035 |

| 19 | 0.042 | 0.038 – 0.042 |

| 18 | 0.049 | 0.044 – 0.049 |

| 17 | 0.058 | 0.053 – 0.058 |

| 16 | 0.065 | 0.060 – 0.065 |

| 15 | 0.072 | 0.066 – 0.074 |

| 14 | 0.083 | 0.075 – 0.085 |

| 13 | 0.095 | 0.087 – 0.097 |

| 12 | 0.109 | 0.101 – 0.111 |

| 11 | 0.12 | 0.112 – 0.122 |

| 10 | 0.134 | 0.126 – 0.136 |

| 9 | 0.148 | 0.140 – 0.150 |

| 8 | 0.165 | 0.157 – 0.167 |

| 7 | 0.18 | 0.175 – 0.185 |

| Types of Incoloy 800 Tube | Out diameter (OD) | Wall thickness |

|---|---|---|

| NB Sizes | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 |

| Nickel 800 Welded Tube | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm |

| Alloy 800 Seamless Tube | 5.0mm ~ 203.2mm | As per requirement |

| Straightness | .030″ in 3″ |

| Wall Tolerance | +/- 10% |

We manufacture ASTM B163 UNS N08800 Tube and W. Nr. 1.4876 Tubes in different standards with very tight tolerance.

| UNS | N08800 |

|---|---|

| International Specifications | ISO 6207, BS3 3074NA15, VdTüV 412 & 434, DIN 17459 |

| Specifications | ASTM B514, ASTM B407, ASTM B775, ASTM B515, ASTM B829, ASTM B751 |

- Bright Annealed

- Annealed & Pickled

- Electropolished

- Mechanical Polished

- Chemical Industry

- Power Generation

- Aerospace

- Marine Applications

- Pharmaceutical Industry

- Furnace tubing

- Cryogenic applications

| Temperature (°C) | Tensile Strength (MPa) |

|---|---|

| 25 | 590 |

| 425 | 511 |

| 540 | 508 |

| 650 | 405 |

| 705 | 319 |

| 760 | 238 |

| Temperature | Shear Modulus |

|---|---|

| °F | 103 ksi |

| -310 | 11.45 |

| 75 | 10.64 |

| 200 | 10.37 |

| 400 | 9.91 |

| 600 | 9.47 |

| 800 | 9.04 |

| 1000 | 8.60 |

| 1200 | 8.12 |

| 1400 | 7.58 |

| 1600 | 6.82 |

| Grade | C | S | Si | Mn | Fe | Cu | Cr | Ni | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 800 | 0.10 max | 0.015 max | 1.00 max | 1.50 max | 39.50 min | 0.75 max | 19.00 – 23.00 | 30.00 – 35.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800H | 0.05 – 0.10 | 0.015 max | 1.00 max | 1.50 max | 39.50 min | 0.75 max | 19.00 – 23.00 | 30.00 – 35.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800HT | 0.06 – 0.10 | 0.015 max | 1.00 max | 1.50 max | 39.50 min | 0.75 max | 19.00 – 23.00 | 30.00 – 35.00 | 0.15 – 0.60ᴬ | 0.15 – 0.60ᴬ |

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|

| 520 MPa | 205 MPa | 30% |

| STANDARD | WNR | UNS | GOST | JIS | BS | AFNOR | OR | EN |

|---|---|---|---|---|---|---|---|---|

| Incoloy 800 | 1.4876 | N08800 | ЭИ670 | NCF 800 | NA 15 | Z8NC32-21 | Xh22T | X10NiCrAlTi32-20 |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | ЭИ670 | NCF 800H | NA 15(H) | Z8NC33-21 | Xh22T | X5NiCrAlTi31-20 |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | ЭИ670 | NCF 800HT | NA 15(HT) | – | Xh22T | X8NiCrAlTi32-21 |

| Density | Melting Range | Specific Heat | Electrical Resistivity |

|---|---|---|---|

| 7.94 g/cm3 | 1357-1385 °C | 460 J/kg. k | 989 µΩ·m |