ASTM B622 UNS N06022 Seamless Tube supplier in India

Alloy C22 ERW Tube can withstand extreme thermal cycling without deformation or failure

Table of content

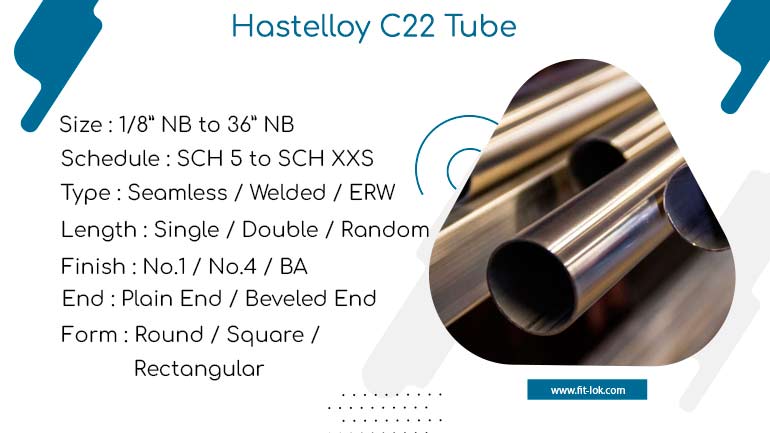

- Hastelloy C22 Tube Specification

- Alloy C22 Tube Types

- Hastelloy C22 tube price

- Difference between Hastelloy C22 VS C276 Tube

- Nickel Alloy C22 seamless tubing size chart

- C22 Hastelloy welded tubing size chart

- ASTM B622 UNS N06022 sanitary tube dimensions

- Surface finish of C22 Hastelloy Tubing

- Wall thickness and OD of ASME SB 622 UNS N06022 Tubes

- Hastelloy UNS N06022 Square Tubing weight chart

- Gauge chart of Alloy NW 6022 Tube

- Nickel C22 Tubing International Standards

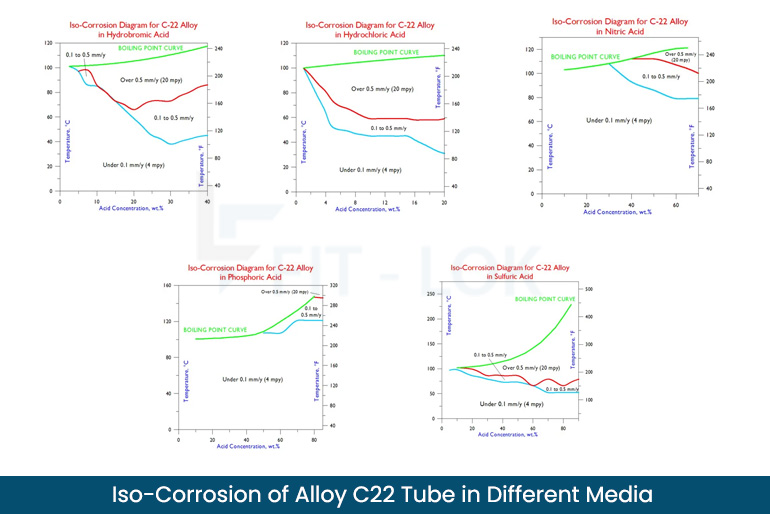

- Iso-Corrosion of Ni C22 Tubing in different media

- NW 6022 Coiled Tubing Stress Corrosion Cracking

- Test certificates of ASTM B619 UNS N06022 Tubing

- UNS N06022 Annealed Tube Applications

- Impact Strength of ASME SB 622 UNS N06022 Cold Rolled Tube

- UNS N06022 Seamless Tube Chemical Composition

- Hastelloy C22 Tubing Mechanical Properties

- Hastelloy C22 tube equivalent

- DIN 2.4602 Round Tube Physical properties

| Specification | ASTM B163 / ASME SB163 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

Hastelloy C22 EFW Tube

Hastelloy C22 High Pressure Tube

C22 Hastelloy Welded Tube

ASTM B622 Alloy C22 Seamless Tubing

Alloy C22 Electropolished Tubes

Nickel C22 ERW Tube

| Product | Price in USD (Mtr) |

Price in Dirham (Mtr) |

Price in Euro (Mtr) |

|---|---|---|---|

| 1/8″ O.D. x .070″ I.D. Hastelloy C22 Tube | US $21.64 | 79.47 AED | € 18.68 |

| 1/32″ O.D. x.005″ I.D x 50cm Alloy C22 Tube | US $22.39 | 82.23 AED | € 19.32 |

If you’re looking for a fair and reasonable price on high Hastelloy C22 Tubing, don’t hesitate to contact us.

| Property | Hastelloy C22 | Hastelloy C276 |

|---|---|---|

| Corrosion Resistance | Superior | Excellent |

| Chromium Content | Higher | Lower |

| Fabricability | Easier to cold form | Slightly tougher to machine |

| Tensile Strength | 690 MPa | 760 MPa |

| Cost | Slightly higher | Slightly lower than C22 |

We offer Nickel C22 High Pressure Tubing and Alloy C22 High Pressure Tube in schedule range of sch 5 to sch xxs.

| Size OD | Wall Thickness |

|---|---|

| (in) | (in) |

| 1/4 (6.350 mm) | 0.035 (0.889 mm) |

| 3/8 (9.525 mm) | 0.035 (0.889 mm) |

| 1/2 (12.7 mm) | 0.065 (1.651 mm) |

| 3/4 (19.05 mm) | 0.065 (1.651 mm) |

| 1 (25.4 mm) | 0.065 (1.651 mm) |

| Size OD (in) | Wall Thickness (in) |

|---|---|

| 1/2 (12.7 mm) | 0.065 (1.651 mm) |

| 3/4 (19.05 mm) | 0.065 (1.651 mm) |

| 1 (25.4 mm) | 0.065 (1.651 mm) |

| 1 1/2 (38.1 mm) | 0.065 (1.651 mm) |

| 2 (50.8 mm) | 0.065 (1.651 mm) |

| 2 1/2 (63.5 mm) | 0.065 (1.651 mm) |

| 3 (76.2 mm) | 0.065 (1.651 mm) |

| 4 (101.6 mm) | 0.083 (2.11 mm) |

Exporter of DIN 2.4602 Electropolished Tubes and UNS N06022 Welded Tube with simplified installation resulting in significant cost reductions

| Tube OD (in) | Tube ID (in) | Wall Thickness (in) |

|---|---|---|

| 1/4 | 0.18 | 0.035 |

| 3/8 | 0.305 | 0.035 |

| 1/2 | 0.37 | 0.065 |

| 3/4 | 0.62 | 0.065 |

| 1 | 0.87 | 0.065 |

| 1 1/2 | 1.37 | 0.065 |

| 2 | 1.87 | 0.065 |

| 2 1/2 | 2.37 | 0.065 |

| 3 | 2.87 | 0.065 |

| 4 | 3.834 | 0.083 |

| 6 | 5.782 | 0.109 |

| 8 | 7.782 | 0.109 |

| Surface Finish | Max Ra |

|---|---|

| Mechanical Polish | 32 µ-inch (0.81 µm) |

| Electropolished | 32 µ-inch (0.81 µm) |

| Unpolished | Mill Finish |

| Types | Out diameter (OD) | Wall thickness |

|---|---|---|

| Seamless Tube | 5.0mm ~ 203.2mm | As per requirement |

| Welded Tube | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm |

| DIMENSIONS | WALL | WEIGHT PER | DIMENSIONS | WALL | WEIGHT PER |

|---|---|---|---|---|---|

| (MM) | (MM) | METRE (KG) | (MM) | (MM) | METRE (KG) |

| 12.7 x 12.7 | 1.5 | 0.55 | 40 x40 | 1.5 | 1.85 |

| 12.7 x 12.7 | 1.2 | 0.44 | 40 x40 | 1.2 | 1.49 |

| 15 x 15 | 1.5 | 0.65 | 40 x40 | 3 | 3.75 |

| 15 x 15 | 1.2 | 0.53 | 40 x40 | 2 | 2.45 |

| 20 x 20 | 1.2 | 0.71 | 50 x50 | 1.5 | 2.32 |

| 20 x 20 | 2 | 1.19 | 50 x50 | 3 | 4.65 |

| 20 x 20 | 1.5 | 0.88 | 50 x50 | 2 | 3.08 |

| 25 x 25 | 1.2 | 0.92 | 60 x60 | 2 | 3.71 |

| 25 x 25 | 2 | 1.49 | 70 x70 | 3 | 6.53 |

| 25 x 25 | 1.5 | 1.14 | 60 x60 | 3 | 5.49 |

| 25 x 25 | 3 | 2.2 | 80 x80 | 2 | 4.98 |

| BWG | mm | in |

|---|---|---|

| 1 | 7.62 | 0.3 |

| 2 | 7.21 | 0.283 |

| 3 | 6.58 | 0.259 |

| 4 | 6.05 | 0.238 |

| 5 | 5.59 | 0.22 |

| 6 | 5.16 | 0.203 |

| 7 | 4.57 | 0.179 |

| 8 | 4.19 | 0.164 |

| 9 | 3.76 | 0.147 |

| 10 | 3.4 | 0.134 |

| 11 | 3.05 | 0.12 |

| 12 | 2.77 | 0.109 |

| 13 | 2.41 | 0.095 |

| 14 | 2.11 | 0.083 |

| UNS | N06022 |

|---|---|

| International Specifications | ISO 6207, din 17751 |

| Specifications | ASTM B619, ASTM B775, ASTM B622, ASTM B626, ASTM B516, ASTM B751 |

| Stress Corrosion Cracking | Outstanding (superior in oxidizing & mixed environments) |

|---|

- Fumigation Certificates

- Heat Treatment Charts

- NABL approved Laboratory Test Reports

- Raw Material Test Reports

- Material Traceability Records

- Quality Assurance Plan

- Guarantee Letter

| Impact Strength | 353 J |

|---|

| Grade | C | Cr | Si | Mn | S | Co | P | Ni | Fe | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| C22 | 0.010 max | 20.00 – 22.50 | 0.08 max | 0.50 max | 0.02 max | 2.50 max | 0.02 max | 50.015 min* | 2.00 – 6.00 | 12.50 – 14.50 |

| Tensile strength | Yield strength | Elongation |

|---|---|---|

| 800 MPa | 407 MPa | 57% |

| STANDARD | WNR | UNS | JIS | GOST | EN | OR |

| Hastelloy C276 | 2.4819 | N10276 | NW 0276 | ХН65МВУ | NiMo16Cr15W | ЭП760 |

| Density | Melting point | Elastic modulus | Thermal conductivity |

|---|---|---|---|

| 8.69 g/cm³ | 1399°C | 206 MPa | 11.1 W/mK |