Leading corrugated stainless steel flexible hose manufacturer in India

We manufacture a range of corrugate stainless steel flexible hoses in varios materials such as 304, 304L, 316 and 316L as per ISO 10380 : 2004. The end connections are TIG Welded by our welders who have been recommended on ASME. Some of the applications where our Flexible Corrugated Hose manufactured by Fit-Lok are Pump Discharge Lines, Crude and Product Pipeline, Bleeder Line, Gas Plant Line, Loading Arm, Refineries, Fertilizer Industries, Petrochemical Plants, Chemical & Pharmaceuticals Plants.

Flexible Corrugated Hose manufactured by Fit-Lok are widely used in refineries, fertilizer industries, petrochemicals plants, chemical and pharmaceuticals plants. Stainless steel flexible metal braid hoses and accessories can therefore be applied on systems such as water, steam, hot oil as well as gas due to their pressure capacity as well as flexibility.

Refer stock list of Corrugated flexible metal hose

Corrugated hoses are thin-walled, cylindrical components of the lateral surface of which has a sinusoidal wave pattern. The type of corrugation used, distinguishes annually corrugated hoses and coil corrugated hoses. We are one of the leading Flexible Corrugated Hose manufacturer in India

Stripwound hoses are manufactured continuously through profiling and helical coiling of a cold rolled metal strip on a mandrel.

Table of content

- Flexible Corrugated Hose specification

- Varios types of corrugated flexible hose

- Corrugated stainless steel flexible hose dimensions

- Advantages of corrugated flexible hoses

- Pressure rating of SS Corrugated Metal Hoses

- Corrugated flexible metal hose temperature range

- High Pressure Corrugated Hose Burst Pressure

- Corrugated Flexible Hoses Sizes

- How to Choose the Right High Pressure Hose?

- Standards for High Pressure Hoses

| FLEXIBLE CORRUGATED HOSE SIZE | 1/4″ TO 12″ |

| SPECIFICATION | BS 6501 / ISO 10380 |

| FLEXIBLE CORRUGATED HOSE END FITTINGS | FLANGES, THREADED FITTINGS, QUICK RELEASE COUPLING , CAMLOCK COUPLING |

| PRESSURE RATING | LOW, MEDIUM, HIGH |

| FLEXIBLE CORRUGATED HOSE MEDIA | HYDRAULIC OIL, AIR, WATER, GAS, STEAM, HOT WATER , COLD WATER , SEA WATER , CHEMICAL |

| MATERIAL | SS 316, SS 304, BRASS, SS 316 TI, CS, COPPER, DUPLEX, INCONEL, SUPER DUPLEX, HASTELLOY, MONEL, ALLOY 20, SMO 254, 904L & TITANIUM, ALL OTHER ALLOYS |

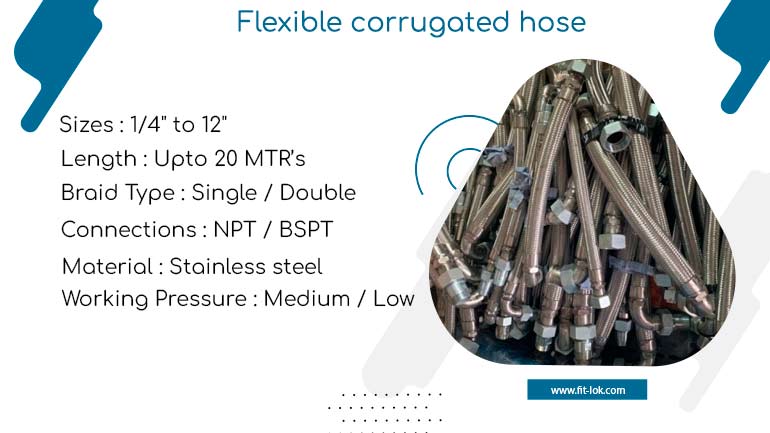

Flexible corrugated hose

Corrugated stainless steel flexible hose

Corrugated flexible metal hose

| Flexible Corrugated Hose Maximum Outside Diameter mm | Standard Packing in mtrs. | Nominal Diameter mm | Corrugated Hose Minimum Bending Radius | Maximum Inside Diameter mm | Coil Length in mtrs. |

|---|---|---|---|---|---|

| 16 ± 0.03 | 250 | 16 | 48 | 11.05 | 50 |

| 20 ± 0.04 | 250 | 20 | 60 | 14.06 | 50 |

| 25 ± 0.04 | 150 | 25 | 75 | 19.00 | 30 |

| 32 ± 0.04 | 150 | 32 | 96 | 24.05 | 30 |

| 40 ± 0.04 | 150 | 40 | 120 | 32.00 | 30 |

| 50 ± 0.05 | 150 | 50 | 150 | 42.02 | 30 |

- They are fire & moisture resistant

- These hoses are a flexible and quick option for rigid piping in difficult locations

- They withstand abrasion, penetration and damage

- They have a longer life and possess very good corrodibility characteristics.

- Suitable for wide temperature ranges

| SIZE | SINGLE BRAID | DOUBLE BRAID | |||||||||

| Nominal Size | Static | Dynamic bend radius | Max. working | Test Pressure | Burst | Static | Dynamic bend radius | Max. working | Test Pressure | Burst | |

| Bend radius | Pressure | Pressure | Bend radius | Pressure | Pressure | ||||||

| Inch | mm | mm | mm | bar | bar | bar | mm | mm | bar | bar | bar |

| 1/4 | 6 | 25 | 100 | 154 | 230 | 616 | 25 | 100 | 246 | 369 | 984 |

| 3/8 | 10 | 40 | 150 | 105 | 157 | 420 | 40 | 150 | 168 | 252 | 672 |

| 1/2 | 12 | 50 | 200 | 88 | 132 | 352 | 50 | 200 | 140 | 210 | 560 |

| 5/8 | 16 | 50 | 200 | 73 | 109 | 292 | 50 | 200 | 116 | 174 | 464 |

| 3/4 | 20 | 70 | 200 | 64 | 96 | 256 | 70 | 200 | 102 | 153 | 408 |

| 1 | 25 | 90 | 200 | 50 | 75 | 200 | 90 | 200 | 80 | 120 | 320 |

| 1¼ | 32 | 110 | 250 | 42 | 63 | 168 | 110 | 250 | 67 | 100 | 268 |

| 1 ½ | 40 | 130 | 250 | 32 | 48 | 128 | 130 | 250 | 51 | 76 | 204 |

| 2 | 50 | 175 | 350 | 31 | 46 | 124 | 175 | 350 | 49 | 73 | 196 |

| 2 ½ | 65 | 200 | 410 | 26 | 39 | 104 | 200 | 410 | 41 | 61 | 164 |

| 3 | 80 | 205 | 450 | 18 | 27 | 72 | 205 | 450 | 28 | 42 | 112 |

| 4 | 100 | 230 | 560 | 16 | 24 | 64 | 230 | 560 | 26 | 39 | 104 |

| 5 | 125 | 280 | 660 | 16 | 24 | 64 | 280 | 660 | 25 | 37 | 100 |

| 6 | 150 | 320 | 815 | 12 | 18 | 48 | 320 | 815 | 20 | 30 | 80 |

| 8 | 200 | 435 | 1015 | 10 | 16 | 40 | 435 | 1015 | 16 | 24 | 64 |

| 10 | 250 | 560 | 1220 | 6.5 | 10 | 26 | 560 | 1220 | 10.5 | 16 | 42 |

| Temperature range | – 200°C to 800°C |

| Burst Pressure | 120 – 1020 Bars |

|---|

| Nominal Bore |

Nominal Bore |

Minimum Bend Radius | Without Braid | Single Braid | Double Braid | ||||

|---|---|---|---|---|---|---|---|---|---|

| N. B. (Inch) | N. B. (mm) | Static (mm) | Flexing (mm) | Max. Pressure Kg/cm2 |

Test Pressure Kg/cm2 |

Max. Pressure Kg/cm2 |

Test Pressure Kg/cm2 |

Max. Pressure Kg/cm2 |

Test Pressure Kg/cm2 |

| 1/4″ | 6 | 25 | 100 | 4 | 6 | 100 | 150 | 160 | 240 |

| 3/8″ | 10 | 40 | 150 | 4 | 6 | 90 | 135 | 144 | 216 |

| 1/2″ | 12 | 50 | 200 | 3 | 4.5 | 80 | 120 | 128 | 192 |

| 5/8″ | 16 | 50 | 200 | 3 | 4.5 | 70 | 105 | 112 | 168 |

| 3/4″ | 20 | 70 | 200 | 2 | 3 | 64 | 96 | 102 | 153 |

| 1″ | 25 | 90 | 200 | 2 | 3 | 50 | 75 | 80 | 120 |

| 1.1/4″ | 32 | 110 | 250 | 1.5 | 2.3 | 40 | 60 | 64 | 96 |

| 1.1/2″ | 40 | 130 | 250 | 1.5 | 2.3 | 30 | 45 | 48 | 92 |

| 2″ | 50 | 175 | 350 | 1 | 1.5 | 28 | 42 | 44 | 66 |

| 2.1/2″ | 65 | 200 | 410 | 1 | 1.5 | 24 | 36 | 38 | 57 |

| 3″ | 80 | 205 | 450 | 1 | 1.5 | 18 | 27 | 28 | 42 |

| 4″ | 100 | 230 | 560 | 0.8 | 1.2 | 16 | 24 | 26 | 39 |

| 5″ | 125 | 280 | 660 | 0.6 | 0.9 | 12 | 18 | 20 | 30 |

| 6″ | 150 | 320 | 816 | 0.6 | 0.9 | 10 | 15 | 16 | 24 |

| 8″ | 200 | 435 | 1015 | 0.5 | 0.75 | 8 | 12 | 12 | 18 |

| ISO | ISO 1436 ISO 3862 ISO 18752 ISO 8330 |

|---|---|

| SAE | SAE J517 SAE J343 SAE J517 100R Series |

| EN Standards | EN 853 EN 856 EN 857 EN ISO 6805 |

| BS | BS 5342 BS 6066 |

| ASTM | ASTM D380 ASTM D412 |