What is Stainless Steel 316?

SS 316 is molybdenum containing austenitic stainless steel which provides more resistance to general corrosion and pitting. It contains 2 to 3% molybdenum and minimum 16% chromium. It offers higher creep, tensile strength and stress-to-rupture at elevated temperatures.

Grade 316 has excellent corrosion resistance in Marine and corrosive media

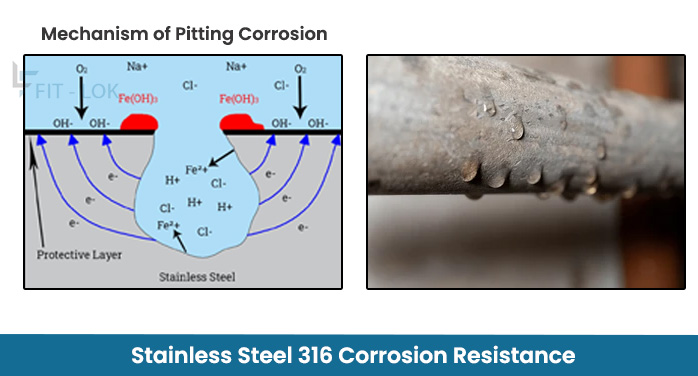

AISI 316 Corrosion Resistance

SS 316 offers excellent corrosion resistance in marine environments, This material is ideal for food equipment, chemical processing and marine industries. Chormium, Nickel and molybdenum content in it provides toughness and good performance in different corrosive media.

UNS S31600 will resist 10% acid under de-aerated conditions

316 Stainless Steel sulphuric acid resistance

It offers good resistance to sulfuric acid, but the performance heavily depend on concentration of acid. Sulphuric acid is oxidising in concentrated condition, and reducing in low or diluted condition. Higher temperature increases the corrosion rate of SS 316 Material even in moderately concentrated acid.

In which enviroments Stainless steel 316 tube is not good?

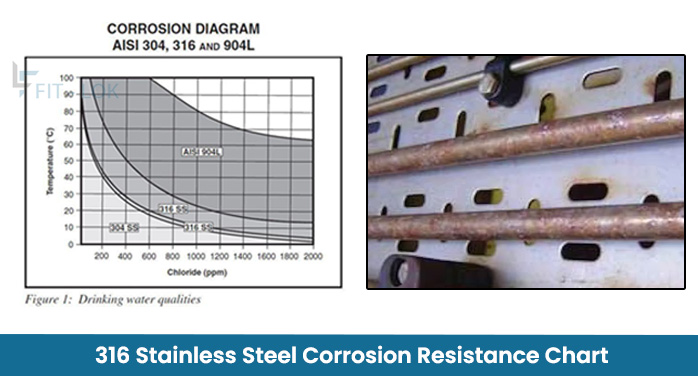

You need to consider higher alloys instead of ASTM A213 TP316 Tube if you have below enviroments:

- Elevated temperature

- High chloride concentration (>1000 ppm)

- Continuous seawater exposure

Molybdenum content makes Type 316 SS more corrosion resistant compared to 304 SS

316 Stainless Steel corrosion resistance chart

Check 316 Stainless Steel Chemical Compatibility Chart online!

View physical properties of Alloy 316 Grade.

Physical properties of SS 316 Material

| Property | Value |

|---|---|

| Electrical Resistivity | 740 nΩ·m |

| Thermal Conductivity | 16.2 W/m·K |

| Modulus of Elasticity | 193 GPa |

| Melting Point | 1370–1400°C |

| Specific Heat Capacity | 500 J/kg·K |

What is corrosion allowance for 316 SS instrument fittings?

Typical industry minimum corrosion allowance for Stainless steel 316 tube fittings is 0.03 inches (0.8 mm).

PREN value for SS316

PREN valve for SS 316 material ranges between 23 to 29.

What are limitation of Type 316 stainless steel?

- AISI 316 Material can pit or crack in high chloride or high temperature environments

- It is susceptible to SSC corrosion above ~60 °C in chlorides

- Can be use be with high concentrations acids like HCl.

Corrosion rate in hydrofluoric acid of SS 316

| Concentration % | Temperature (oC) | Time | Corrosion rate | |

|---|---|---|---|---|

| mpy | Mm/y | |||

| 10 % | 16 oC | 30 days | .1 mpy | .002 Mm/y |

| 12 % | 83 oC | 7.2 days | 700 mpy | 18 Mm/y |

| 38 % | 110 oC | 2 days | 2000 mpy | 51 Mm/y |

| 40 % | 20 oC | – | Poor | Poor |

| 60 % to 65 % | -1.1 oC to 26 oC | 28 days | Poor | Poor |

| 70 % | 21 oC | 42 days | 49 mpy | 1.24 Mm/y |

| 72 % | 176 oC | 14 days | 240 mpy | 6 Mm/y |

| 72 % | 176 oC | 14 days | 380 mpy | 10 Mm/y |

| 98 % | 34 oC to 44 oC | 3.5 days | 2 mpy | .05 Mm/y |