Difference between Ball Valve and Needle Valve

| Feature | Ball Valve | Needle Valve |

|---|---|---|

| Flow Control | Poor | Excellent |

| Operating Torque | Low | Medium/High |

| Pressure Capability | Moderate to very high | Very high |

| Flow Characteristics | High flow | Low flow |

| Cost | Lower | Higher |

Ball valves can be quickly shut off and on

What is Ball Valve?

Instrument ball valve is a flow control device. These Stainless steel ball valve are essential components in instrumentation process. It helps to provide reliable shut off for gases and liquids. These valves are characterized by their compact dimensions, end connections.

Needle Valve offers precise flow control compared to instrumentation ball valve.

What is Needle Valve?

Needle valve is used to accurately control flow rate of gases or liquids. Stainless steel needle valve consist of Valve body, Bonnet, Stem, Needle and Seat. These valves comes in port size of 1/8″ to 2″. These valves are known for Accurate flow control and Leak Tight Shutoff.

What is Flow control?

Basically flow control is limiting or regulating the flow of gases, liquids or any other media which is passing through instrumentation system. It helps to control pressure and ensure smooth operation.

Flow rate and Pressure Handling are criteria to choose between Needle or Ball Valves

How to choose right Ball Valve and Needle Valve?

If you want to control when fluid should flow through pipeline at high flow rate then you should choose Instrument Ball Valve. If you want to adjust the flow rate of fluid or gas accurately then needle valve is the right choice.

Things to remember while ordering Ball valve or Needle Valve:

- Pressure capability

- Operating Temperature

- Pipe Size

- Connection Type

- Sealing requirements

- Material compatibility

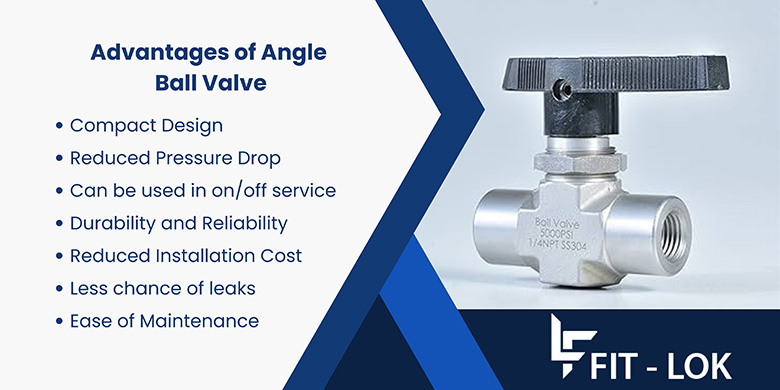

Advantages of Angle ball valve

Benefits of Cryogenic needle valve

Application of Needle Valve and Ball Valve

| Needle Valve Application | Ball Valve Application |

|---|---|

| Instrumentation and Control | Pipeline Isolation |

| Cryogenics | HVAC Systems |

| Sampling Lines | Gas Lines |

| High Pressure Gas Control | Marine and Ship Systems |

| Calibration Systems | Fire Protection Systems |

Conclusion

So we can say instrumentation ball valve is ideal in quick operation, high flow, and low-pressure drop condition whereas Needle valve is designed for precise flow control.

If you are looking to buy Ball valve or Needle valve in any material or sizes, Please feel free to contact us on sales@fit-lok.com