What is ASTM A269?

ASTM A269 is manufacturing standard for Austenitic Stainless Steel seamless and welded tubes for general services. This standard defines sizes, thickness, mechanical properties and testing requirements of tubes.

ASTM A213 standards covers stainless steel and alloy steel materials for manufacturing

What is ASTM A213?

ASTM A213 is standard specification for Seamless Boiler and Heat Exchanger Tubes in Ferritic and Austenitic grades like Alloy steel and Stainless steel. It covers sizes, thickness, tolerance and pressure rating of tubes.

SA213 Tubing can withstand high temperature compared too ASTM A269

What is the difference between ASTM A213 and A269

| Feature | ASTM A213 Tube | ASTM A269 Tube |

|---|---|---|

| Primary Use | High temp boilers and heat exchangers tubes | General service and instrumentation |

| Manufacturing | Seamless | Seamless or Welded |

| Wall Thickness | Usually Minimum Wall (0% / +20%) | Average Wall (+/- 10%) |

| Hydrostatic Test | Mandatory | Optional |

| Finish | Pickled / Bright Annealed | Bright Annealed / Polished |

ASTM A213 vs ASTM A269 Cost

ASTM A213 is more expensive as compared to ASTM A269 due to its strict manufacturing standards, minimum wall thickness and rigorous testing.

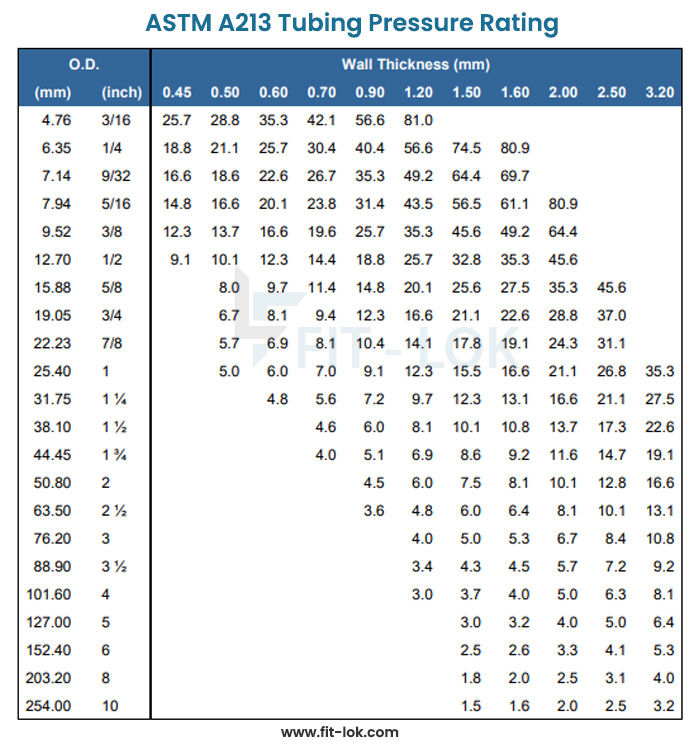

ASME SA213 vs SA269 Pressure Rating

Tubes manufactured according to ASTM A213 standards are used in high temperature and high pressure application whereas ASTM A269 is for General Service standard. Also A213 tubes have minium wall thickness compared to its compared which have average wall thickness. Due to stricter Testing and manufacturing standards ASTM A213 tubes can withstand more pressure than ASTM A269.

ASME SA213 Tubes have even wall thickness across length

SA213 vs SA269 Wall Thickness

ASTM A213 specifies minimum wall thickness which means if you have ordered 1mm thickness ASME SA213 TP304 tube it can never be thinner than 1mm at any point. Whereas A269 specifies an average wall thickness, which means at some spots tube can be thinner than what you ordered.

Difference between manufacturing methods of ASTM A213 vs A269

ASTM A213 is strictly seamless manufacturing specification, while ASME SA269 can be manufactured in both seamless and welded types. ASME SA213 are manufactured using Extrusion or Hot Rolling method compared to its conterpart which can be manufactured by ERW, EFW or cold working methods.

SA269 standard have wall tolerance of +/- 10%

Testing Requirements of ASME SA213 Vs SA269

SA213 standard required undergo either a Hydrostatic or Eddy Current test, whereas for ASME SA269 standard these tests are optional. To test if tubes can withstand stress of thermal expansion, Tension, Flattening, Flaring, and Hardness tests needs to be done on A213 tubes.

How to choose between A213 vs A269 standard for your application?

For high pressure and high temperature application such as boilers, heat exchangers we recommend to use ASME SA213 standard tubes. Whereas for general applications like chemical processing, pharmaceutical and dairy equipment you can use ASTM A269 standards tubes as they dont required high pressure ratings.