Biggest ASME SA270 Polished Dairy Tube Supplier in India

Don’t forget to check A270 Stainless Steel Tubing Dimensions and Weight Chart

Table of content

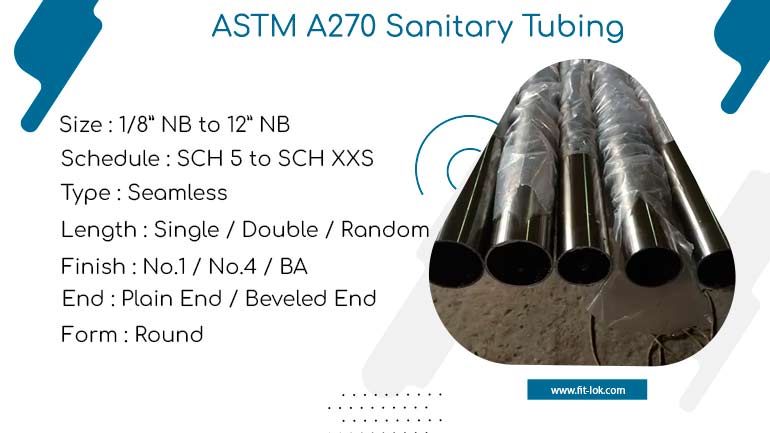

| Specification | ASTM A270 / ASME SA 270 |

| Outer Diameter | 1/2 Inch |

| Wall Thickness | 16 Gauge (0.065 Inch) |

| Length | 20 Inch |

| Polish | Mechanical Polished |

| Type | Seamless |

| Finish | 20Ra Inner Diameter/ 32Ra Outer Diameter |

| Grades | SS 304, SS 304L,SS 316,SS 316L |

| Outer Diameter Tolerance | +/-0.005” / +/-0.13MM |

| Wall Thickness Tolerance | +/-10% |

| Mill Test Certificate | EN10204 3.1 |

| Certification | 3A – Food / Dairy Grade |

| Length Tolerance | +1/8” / +3.18MM |

| Standard | 3A / ASTM A270 / A270M |

A270 Stainless Steel Tubing

ASTM A270 Tp316l

ASTM A270 Tp304

A270 Sanitary Tubing

A270 Polished Dairy Tube

ASTM A270 Tubing

Benefit from competitive rates on top-grade A270 Sanitary Tubing supplied by trusted vendors in India

| Finish Code | Contact Surface Finish Treatment (ID) | Contact Surface (Max Ra)* | Non-Product Contact Surface (Max Ra) |

|---|---|---|---|

| -PM | Electropolished | 15 µ-inch(0.38 µm) | 32 µ-inch(0.81 µm) |

| -PL | Mechanical Polish | 20 µ-inch(0.51 µm) | 32 µ-inch(0.81 µm) |

- Size: 1/2″ – 8″

- WT: .019″ – .145″

- Lengths: 1″ – 60′

We take pride in being the leading stockist and distributor, ensuring prompt availability of high-temperature A270 Polished Dairy Tube.

| Size Outer Diameter | Wall Thickness | Length Tolerance | Outside Diameter Tolerance | Wall Thickness Tolerance | ||||

|---|---|---|---|---|---|---|---|---|

| mm | Inch | mm | Inch | mm | Inch | mm | Inch | () |

| 50.8 | 2 | 1.65 | 0.065 | 3.18 | ⅛ | 0.20 | 0.008 | 10.0 |

| 19.1 | ¾ | 1.65 | 0.065 | 3.18 | ⅛ | 0.13 | 0.005 | 10.0 |

| 38.1 | 1½ | 1.65 | 0.065 | 3.18 | ⅛ | 0.20 | 0.008 | 10.0 |

| 12.7 | ½ | 1.65 | 0.065 | 3.18 | ⅛ | 0.13 | 0.005 | 10.0 |

| 63.5 | 2½ | 1.65 | 0.065 | 3.18 | ⅛ | 0.25 | 0.010 | 10.0 |

| 25.4 | 1 | 1.65 | 0.065 | 3.18 | ⅛ | 0.13 | 0.005 | 10.0 |

| 76.2 | 3 | 1.65 | 0.065 | 3.18 | ⅛ | 0.25 | 0.010 | 10.0 |

| 101.6 | 4 | 2.11 | 0.083 | 3.18 | ⅛ | 0.38 | 0.015 | 10.0 |

| 152.4 | 6 | 2.77 | 0.109 | 25.4 | 1 | 0.76 | 0.030 | 10.0 |

| Nominal Pipe Size in Inch | Schedule 40 | Schedule 10 | ||

|---|---|---|---|---|

| 304L | 316L | 304L | 316L | |

| 1/2 | A312P4-4050 | A312P4-6050 | A312P1-4050 | A312P1-6050 |

| 3/4 | A312P4-4075 | A312P4-6075 | A312P1-4075 | A312P1-6075 |

| 1 | A312P4-4100 | A312P4-6100 | A312P1-4100 | A312P1-6100 |

| 1-1/4 | A312P4-4125 | A312P4-6125 | A312P1-4125 | A312P1-6125 |

| 1-1/2 | A312P4-4150 | A312P4-6150 | A312P1-4150 | A312P1-6150 |

| 2 | A312P4-4200 | A312P4-6200 | A312P1-4200 | A312P1-6200 |

| 2-1/2 | A312P4-4250 | A312P4-6250 | A312P1-4250 | A312P1-6250 |

| 3 | A312P4-4300 | A312P4-6300 | A312P1-4300 | A312P1-6300 |

| 4 | A312P4-4400 | A312P4-6400 | A312P1-4400 | A312P1-6400 |

| 6 | A312P4-4600 | A312P4-6600 | A312P1-4600 | A312P1-6600 |

| 8 | A312P4-4800 | A312P4-6800 | A312P1-4800 | A312P1-6800 |

| 10 | A312P4-41000 | A312P4-61000 | A312P1-41000 | A312P1-61000 |

| 12 | A312P4-41200 | A312P4-61200 | A312P1-41200 | A312P1-61200 |

| Outer diameter in Inch | Dimensions | ||

| Wall Thickness | Inner Diameter | Gauge | |

| 1 | 0.065 | 0.870 | 16 |

| 2 | 0.065 | 1.870 | 16 |

| 4 | 0.065 | 3.870 | 16 |

| 3 | 0.120 | 2.760 | 11 |

| 2 | 0.120 | 1.760 | 11 |

| 2-1/2 | 0.065 | 2.370 | 16 |

| 1/2 | 0.065 | 0.370 | 16 |

| 3 | 0.065 | 2.870 | 16 |

| 4 | 0.083 | 3.834 | 14 |

| 1-1/2 | 0.065 | 1.370 | 16 |

| 6 | 0.083 | 5.834 | 14 |

| 3/4 | 0.065 | 0.620 | 16 |

| 6 | 0.109 | 5.782 | 12 |

| 8 | 0.109 | 7.782 | 12 |

| 10 | 0.109 | 9.782 | 12 |

| 5 | 0.083 | 4.834 | 14 |

| 12 | 0.109 | 11.782 | 12 |

Cost-effective ASTM A270 Tubing from trusted suppliers in India

| Elements | Composition |

|---|---|

| Phosphorus | 0.045 |

| Sulphur | 0.030 |

| Sulphur | 0.005-.017 |

| Silicon | 0.750 |

| Manganese | 2.000 |

| Nickel | 10.0-14.0 |

| Carbon | 0.030 |

| Chromium | 16.0-18.0 |

| Molybdenum | 2.0-3.0 |

Application of Astm A270 Tubing

- Marine applications

- Aerospace industry

- Water treatment

- Automotive applications

- HVAC systems