We are ASME SA 269 TP 316 Seamless Tubing Supplier in India

Our SA269 Tubing are manufactured using high-grade material, ensuring excellent corrosion resistance and durability.

Table of content

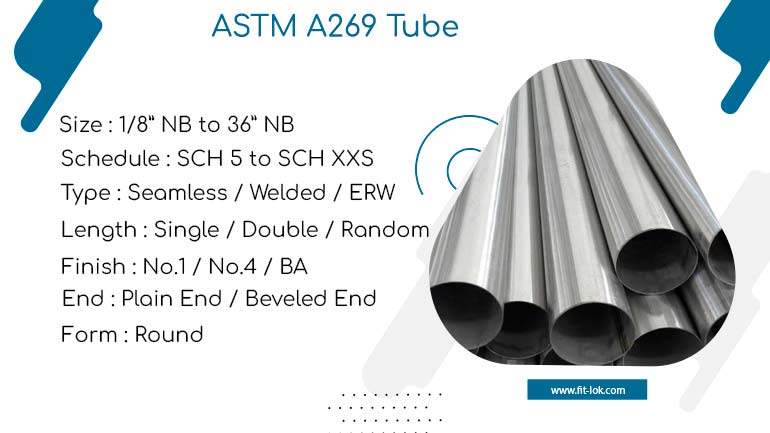

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

View Schedule Chart and updated price list of ASME SA269 Tubes

ASME SA 269 TP 316 Seamless Tubing

ASME SA269 Tubes

ASTM A269 Seamless Tubing

ASTM A269 SS Tubing

ASME SA 269 Seamless Tube

ASTM A269 Standard Tubing

ASTM A269 Seamless Tubing manufacturer in Mumbai

| Grade | Carbon | Nickel | Manganese | Sulfur | Silicon | Phosphorus | Chromium | Niobium | Molybdenum | Titanium |

|---|---|---|---|---|---|---|---|---|---|---|

| TP321 | 0.08 | 9.0-12.0 | 2.00 | 0.030 | 1.00 | 0.045 | 17.0-19.0 | 5C -0.70 | ||

| TP304 | 0.08 | 8.0-11.0 | 2.00 | 0.030 | 1.00 | 0.045 | 18.0-20.0 | |||

| TP316 | 0.08 | 10.0-14.0 | 2.00 | 0.030 | 1.00 | 0.045 | 16.0-18.0 | 2.00-3.00 | ||

| TP304L | 0.035 | 8.0-12.0 | 2.00 | 0.030 | 1.00 | 0.045 | 18.0-20.0 | |||

| TP316L | 0.035 D | 10.0-15.0 | 2.00 | 0.030 | 1.00 | 0.045 | 16.0-18.0 | 2.00-3.00 | ||

| TP347 | 0.08 | 9.0-12.0 | 2.00 | 0.030 | 1.00 | 0.045 | 17.0-19.0 | 10C -1.10 |

| Grade | Temperure F (C) | Heat treatment | Hardness | |

|---|---|---|---|---|

| Brinell | Rockwell | |||

| TP304 | 1900 (1040) | Solution | 192HBW/ 200HV | 90HRB |

| TP304L | 1900 (1040) | Solution | 192HBW/ 200HV | 90HRB |

| TP316 | 1900(1040) | Solution | 192HBW/ 200HV | 90HRB |

| TP316L | 1900(1040) | Solution | 192HBW/ 200HV | 90HRB |

| TP321 | 1900(1040) F | Solution | 192HBW/ 200HV | 90HRB |

| TP347 | 1900(1040) | Solution | 192HBW/ 200HV | 90HRB |

| SAE grade | EN-standard Steel name |

UNS | EN-standard |

|---|---|---|---|

| 409 | X6CrTi12 | S40900 | 1.4512 |

| 410 | S41000 | ||

| 301 | X10CrNi18-8 | S30100 | 1.4310 |

| 301LN | X2CrNiN18-7 | 1.4318 | |

| 304L | X2CrNi18-9 | S3043 | 1.4307 |

| 316 | G-X 6 CrNiMo 18-10 | S31600 | 1.4408 |

| 304L | X2CrNi19-11 | S30403 | 1.4306 |

| 304LN | X2CrNiN18-10 | S30453 | 1.4311 |

| 310 | X22CrNi2520 | S31000 | 1.4841 |

| 304 | X5CrNi18-10 | S30400 | 1.4301 |

| 304H | X6CrNi18-11 | S30409 | 1.4948 |

| 316LN | X2CrNiMoN17-12-2 | S31653 | 1.4406 |

| 305 | X5CrNi18-12 | S30500 | 1.4303 |

| 312 | X5CrNi30-9 | ||

| 310S | X 5 CrNi 2520 | S31008 | 1.4845 |

| 321 | X6CrNiTi18-10 | S32100 | 1.4541 |

| 316 | X3CrNiMo17-13-3 | S31600 | 1.4436 |

| 321H | X12CrNiTi18-9 | S32109 | 1.4878 |

| 2304 | X2CrNi23-4 | S32304 | 1.4362 |

| 316L | X2CrNiMo17-12-2 | S31603 | 1.4404 |

| 316 | X5CrNiMo17-12-2 | S31600 | 1.4401 |

| 316L | X2CrNiMo17-12-3 | S31603 | 1.4432 |

| 316L | X2CrNiMo18-14-3 | S31603 | 1.4435 |

| 316Ti | X6CrNiMoTi17-12-2 | S31635 | 1.4571 |

| 316LN | X2CrNiMoN17-13-3 | S31653 | 1.4429 |

| 317L | X2CrNiMo18-15-4 | S31703 | 1.4438 |

| 2205 | X2CrNiMoN22-5-3 | S31803/S32205 | 1.4462 |

| J405 | X2CrNiMoCuWN25-7-4 | S32760 | 1.4501 |

| 904L | X1NiCrMoCu25-20-5 | N08904 | 1.4539 |

| X1NiCrMoCuN25-20-7 | N08926 | 1.4529 | |

| 254SMO | X1CrNiMoCuN20-18-7 | S31254 | 1.4547 |

For reliable and superior-grade high-temperature ASTM A269 SS Tubing, our leading stockist and distributor services are unmatched.

| Nominal Pipe Size | Tolerance, % | |

|---|---|---|

| + | – | |

| ≥ 20, seamless, t/D≤ 5% | 22.5 | 12.5 |

| 3~18, t/D≤ 5% | 22.5 | 12.5 |

| ≥ 20, seamless, t/D> 5% | 15.0 | 12.5 |

| 1/8-2 1 /2 | 20.0 | 12.5 |

| 3~18, t/D> 5% | 15.0 | 12.5 |

| ≥ 20, welded | 17.5 | 12.5 |

Application of ASTM A269 SS Tubing

- Water treatment

- HVAC systems

- Automotive applications

- Aerospace industry

- Marine applications