Reliable Carpenter 20 Ball Valve Manufacturer in India

Check Weight Chart of DIN 2.4660 Panel Mounted Ball Valve

Table of content

- Alloy 20 ball valve specification

- Alloy 20 instrumentation ball valve chemical composition

- Carpenter 20 Panel Mounted Ball Valve Mechanical properties

- Equivalent grade of DIN 2.4660 ball valves

- Pressure Rating Of Alloy 20 ball valve

- Size Chart of UNS N08020 3 way ball valve

- Various types of Alloy 20 ball valves

- Design Features of DIN 2.4660 Ferrule Ball Valve

- UNS N08020 High Pressure Ball Valves application

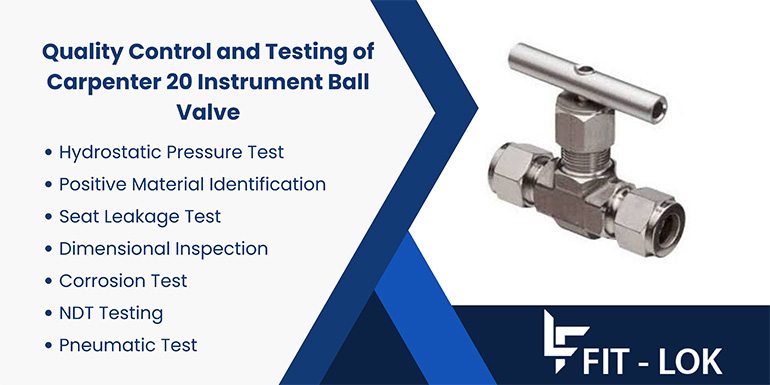

- Quality Control and Testing of Carpenter 20 Instrument Ball Valve

- Heat treatment of Alloy 20 Cryogenic Ball Valves

| Size | 1/4″ to 4″ |

| Standards | API 608 / ASME B16.34 / ISO 17292 |

| Valve Type | 2 Way / 3 Way |

| Bore Type | Full Bore / Reduced Bore |

| Pressure Rating | 3000 PSI / 6000 PSI / 10000 PSI / 15000 PSI |

| End Connections | Socket Weld / Female / Male NPT / Double Ferrule Compression |

| Flow Rate | .93, 2.34, 6.42, .70, 1.04, 3.62,.87 Cv |

| Fire Safe Design | API 607 / ISO 10497 |

| Surface Finish | Pickled / Machined / Electropolished |

| Approvals |

|

| C | Cr | Mn | Cu | S | Ni | Si | Mo | Fe | P |

|---|---|---|---|---|---|---|---|---|---|

| 0.07 max | 19.00 – 21.00 | 2.00 max | 3.00 – 4.00 | 0.035 max | 32.00 – 38.00 | 1.00 max | 2.00 – 3.00 | 29.85 min* | 0.045 max |

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|

| 551 MPa | 241 MPa | 30% |

| Standard | EN | UNS | WNR | AFNOR |

|---|---|---|---|---|

| Alloy 20 | NiCr20CuMo | N08020 | 2.466 | Z2NCUD31-20AZ |

| Valve Size | Max Operating Pressure | Max Operating Temp |

|---|---|---|

| 1/8” – 1/4” | 6000 psi | 200–300°F |

| 1/4” – 1/2” | 5000–6000 psi | 200–300°F |

| Size | D | A | C | B | I | F | E | Weight (Lbs) |

|---|---|---|---|---|---|---|---|---|

| 1/4″ | 1.42 | 2.84 | 2.44 | 5.12 | 0.25 | 2.18 | 1.54 | 2 |

| 3/8″ | 1.42 | 2.84 | 2.44 | 5.12 | 0.375 | 2.18 | 1.54 | 2 |

| 1/2″ | 1.63 | 3.27 | 2.52 | 5.12 | 0.5 | 2.5 | 1.62 | 2 |

| 3/4″ | 1.95 | 3.9 | 3.23 | 6.5 | 0.75 | 2.95 | 1.93 | 3 |

| 1″ | 2.2 | 4.41 | 3.5 | 6.5 | 1 | 3.45 | 2.17 | 5 |

| 1-1/4″ | 2.46 | 4.93 | 3.86 | 8.08 | 1.25 | 3.97 | 2.48 | 6 |

| 1-1/2″ | 2.93 | 5.87 | 4.25 | 8.08 | 1.5 | 4.66 | 2.92 | 11 |

| 2″ | 3.42 | 6.85 | 5.52 | 12.81 | 2 | 5.88 | 3.66 | 20 |

Alloy 20 Hydraulic Ball Valves

Carpenter 20 High Pressure Ball Valves

DIN 2.4660 Cryogenic Ball Valves

Alloy 20 Compression Ball Valves

UNS N08020 Instrument Ball Valve

EN 2.4660 Flow Control Ball Valves

- Superior resistance to stress corrosion

- Excellent mechanical properties

- Excellent general corrosion resistance to sulfuric acid

- Can be used in SO2 scrubbers

- Minimal carbide precipitation during welding

- Condensate systems

- Gas desulfurization systems

- Wastewater applications

- Cooling water systems

- Pharmaceutical equipment

- Pickling racks

| Condition | Temperature | Type | Cooling | Time |

|---|---|---|---|---|

| Annealed or Spring Temper | 250 – 530 °C (480 – 990 °F) | Stress Relieve | Air | 1 Hr |