Check sizes and dimensions of 700 Bar Flow Control Check Valve

We are supplier and exporter of 10000 psi directional control valve

Table of content

- 10000 PSI Check Valve Specification

- 10000 psi hydraulic check valve manufacturing standard

- Different types of 700 Bar Check Valve

- Price list of 10000 psi flow control check valve

- 10000 PSI High Pressure Check Valve dimensions

- Parts and material of 700 Bar High Pressure Check Valve

- Male X Male 700 Bar Check Valve dimensions

- 10000 Psi Male X Female Check Valve dimensions

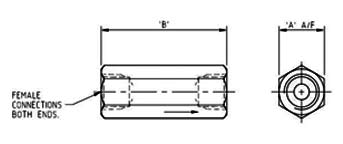

- Female X Female 10000 Psi Check Valve dimensions

- Quality testing of 10000 Psi Pilot Operated Check Valve

- 10000 PSI NRV Valve Application

- Female X Female 10000 Psi Check Valve Advantages

- Working Temperature and Cracking Pressure of 10000 PSI Check Valve

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

- ASME B16.34

- MSS SP-55

- BS 1868

- ASME B16.10

- API 6D / API 598

- MSS SP-25

- ASME B16.5

10000 psi hydraulic check valve

700 Bar Check Valve

Female X Female 10000 Psi Check Valve

Male X Female 10000 Psi Check Valve

10000 psi flow control check valve

Male X Male 10000 Psi Check Valve

Refer dimensions and price list of 10000 psi hydraulic check valve

| Product | Price (Per Piece) |

|---|---|

| 1/8″ SS Check Valves Female, NPT, 10,000 psi | US $ 20.88 |

| 1/4″ SS Check Valves Female, NPT, 10,000 psi | US $ 25.42 |

| 1″ SS Check Valves Female, NPT, 10,000 psi | US $ 40.42 |

| Thread Size | Max Pressure | ‘A’ A/F | ‘B’ | Cracking Pressure | Weight |

| 1/4″ | 6,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.2kg |

| 1/4″ | 10,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.3kg |

| 3/8″ | 6,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.3kg |

| 3/8″ | 10,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.8kg |

| 1/2″ | 6,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.2kg |

| 1/2″ | 10,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.3kg |

| 3/4″ | 3,000 PSI | 1.3″ | 3 5/8″ | 4 PSI | 0.3kg |

| 3/4″ | 6,000 PSI | 1.5″ | 3 5/8″ | 4 PSI | 0.8kg |

| 1″ | 3,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| 1″ | 6,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| Description | Material |

|---|---|

| Body | SS316L |

| Piston | SS316L |

| Gland Washer | SS316L |

| Wheel | SS316L |

| Side Adaptor | SS316L |

| Spring | SS |

| Pressure Rating 100°F (37°C) PSIG | END CONNECTIONS | DIMENSIONS MM | Cv | |

| INLET / OUT LET | L | A/F | ||

| 10000 | 1/8″ | 60 | 19 | 0.82 |

| 10000 | 1/4″ | 68 | 22 | 1.4 |

| 10000 | 3/8″ | 70 | 25 | 1.52 |

| 10000 | 1/2″ | 82 | 27 | 1.7 |

| 10000 | 3/4″ | 85 | 36 | 4.85 |

| 10000 | 1″ | 92 | 45 | 8.3 |

| Pressure Rating 100°F (37°C) PSIG | End Connections |

Hex | Length | |

| Inlet / Out Let | (mm) | (mm) | ||

| 10000 psi | 1/8″ NPT M | 1/8″ NPT F | 19 | 55 |

| 10000 psi | 1/4″ NPT M | 1/4″ NPT F | 22 | 58 |

| 10000 psi | 3/8″ NPT M | 3/8″ NPT F | 25 | 65 |

| 10000 psi | 1/2″ NPT M | 1/2″ NPT F | 27 | 72 |

| 10000 psi | 3/4″ NPT M | 3/4″ NPT F | 36 | 82 |

| 10000 psi | 1″ NPT M | 1″ NPT F | 45 | 85 |

| Pressure Rating 100°F (37°C) PSIG | End Connections | Hex | Length | |

| Inlet / Out Let | (mm) | (mm) | ||

| 10000 psi | 1/8″ NPT F | 1/8″ NPT F | 19 | 55 |

| 10000 psi | 1/4″ NPT F | 1/4″ NPT F | 22 | 58 |

| 10000 psi | 3/8″ NPT F | 3/8″ NPT F | 25 | 65 |

| 10000 psi | 1/2″ NPT F | 1/2″ NPT F | 27 | 72 |

| 10000 psi | 3/4″ NPT F | 3/4″ NPT F | 36 | 82 |

| 10000 psi | 1″ NPT F | 1″ NPT F | 45 | 85 |

Various destructive and non destructive testings are done of 700 Bar Check Valve

- Hydrostatic Testing

- Leak Testing

- Burst Pressure Testing

- Pilot Pressure Sensitivity

- Flow Direction and Blocking Performance

- Material Quality Testing

- Seat Leakage Test

- Pilot Leakage Test

Male X Male 10000 Psi Check Valve are available in NPT, BSP and BSPT threads

- Chemical processing plants

- Hydraulic systems

- Nuclear power plants

- Gas compression systems

- Power plants

- High Pressure Capability

- Reliable Backflow Prevention

- Compact Design

- Multiple Connection Options

- Low Operating Torque

- Factory Tested

| Working Temperature | -10°F to 392°F |

|---|---|

| Cracking Pressure | 1psi to 25psi |