Alloy 2205 Spring Check Valve Manufacturer in India

View sizes and price list of Duplex Poppet Check Valve

Table of content

- Duplex Check Valve Specification

- Duplex 2205 Check Valves price list

- Types of DSS Check Valves

- Documentation of Alloy 2205 Inline Check Valves

- Manufacturing and design standards of Duplex Non-return Valve

- Duplex Stainless Steel Check Valve chemical composition

- DSS Spring Check Valve mechanical properties

- Duplex Poppet Check Valve equivalent grade

- Dimensions of Duplex 2205 Check valve

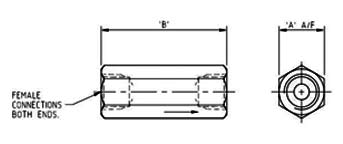

- Alloy 2205 Female to Female Check valve dimensions

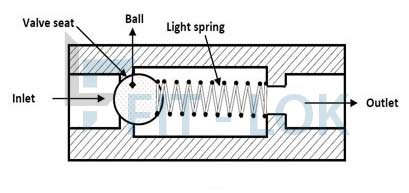

- Duplex Spring Check Valve Diagram

- Benefits of ASTM A276 Type 2205 One Way Check Valve

- ASTM A276 Type 2205 Control Check Valve Applications

- Heat Resistance of UNS S32205 Non Return Check Valves

Supplier of UNS S32205 Non Return Check Valves in different pressure rating and threads

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Price of Alloy 2205 Inline Check Valves vary between 15$ to 150$ per piece based on size, material, pressure rating, design and flow rate. For updated price list of Duplex Stainless Steel Check Valve you can contact us on sales@fit-lok.com

Duplex Hydraulic Check Valve

Alloy 2205 Inline Check Valve

Duplex Stainless Steel Nrv Valve

ASTM A479 UNS S31803 Instrument Air Check Valve

Duplex 2205 Non Return Valve

ASTM A276 Type 2205 Spring Check Valve

UNS S31803 Instrumentation Check Valve

Duplex steel Poppet Check Valve

SAF 2205 Instrument Control Valve

- Mill Test Certificates

- EN 10204 3.1

- Chemical Reports

- PMI Test Reports

- Mechanical Reports

- Non Destructive Test Reports

- NABL Approved Lab Reports

- Visual Inspection Reports

- Destructive Test Report

- Third Party Inspection Reports

| Standards | ISO 14313:1999 or API 6D |

| Inspection Standard | API 598. |

| Manufacturer of Grade | A890/A995 2A CE8MN A8901A/A995 3A CD4MCu A890/A995 4A CD3MN A890/A995 1B CD4MCuN |

| Face to Face Standard | As per ASME B 16.10 |

| Testing Standards | API Standard 594 |

ASTM A276 Type 2205 One Way Check Valve are extremely corrosion resistant in chloride and sulphide environments

| Grade | Ni | Mn | Si | C | S | Cr | P | N | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| S31803 | 4.50 – 6.50 | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 0.030 max | 0.14 – 0.20 | 3.0 – 3.5 | 63.72 min |

| S32205 | 4.50 – 6.50 | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 0.030 max | 0.8 – 0.20 | 2.50 – 3.50 | 63.54 min |

| Grades | Density (lb/in 3) | Density (g/cm 3) | Melting Point (°F) | Melting Point (°C) |

|---|---|---|---|---|

| S31803 / S32205 | 0.285 | 7.805 | 2588 – 2669 | 1420 – 1465 |

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Duplex 2205 | 1.4462 | S31803 / S32205 |

| Thread Size | Max Pressure | ‘A’ A/F | ‘B’ | Cracking Pressure | Weight |

| 1/4″ | 6,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.2kg |

| 1/4″ | 10,000 PSI | 0.87″ | 2 5/16″ | 7 PSI | 0.3kg |

| 3/8″ | 6,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.3kg |

| 3/8″ | 10,000 PSI | 1.1″ | 2 1/2″ | 7 PSI | 0.8kg |

| 1/2″ | 6,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.2kg |

| 1/2″ | 10,000 PSI | 1.1″ | 3 1/8″ | 7 PSI | 0.3kg |

| 3/4″ | 3,000 PSI | 1.3″ | 3 5/8″ | 4 PSI | 0.3kg |

| 3/4″ | 6,000 PSI | 1.5″ | 3 5/8″ | 4 PSI | 0.8kg |

| 1″ | 3,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| 1″ | 6,000 PSI | 1.875″ | 4 3/16″ | 4 PSI | 0.9kg |

| END CONNECTIONS | PRESSURE RATING 100°F (37°C) PSIG | Hex | Length | |

| INLET / OUT LET | (mm) | (mm) | ||

| 1/8″ NPT F | 1/8″ NPT F | 15000 psi | 19 | 55 |

| 1/4″ NPT F | 1/4″ NPT F | 15000 psi | 22 | 58 |

| 3/8″ NPT F | 3/8″ NPT F | 15000 psi | 25 | 65 |

| 1/2″ NPT F | 1/2″ NPT F | 15000 psi | 27 | 72 |

| 3/4″ NPT F | 3/4″ NPT F | 15000 psi | 36 | 82 |

| 1″ NPT F | 1″ NPT F | 15000 psi | 45 | 85 |

We are leading exporter of Alloy 2205 Inline Check Valves in Indonesia, UAE and Qatar

- High strength

- Ductility and toughness

- Corrosion resistance

- Temperature resistance

- High-temperature oxidation resistance

- Desalination plants

- Petrochemical industries

- Chloride-handling industries

- Chemical processing

- Marine environments

- Oil and Gas industry

| Heat Resistance | 1020-1100 oC |

|---|