Alloy 625 Poppet Check Valves Manufacturer in India

Buy Inconel 600 Instrumentation Check Valve at 20% discounted price

Table of content

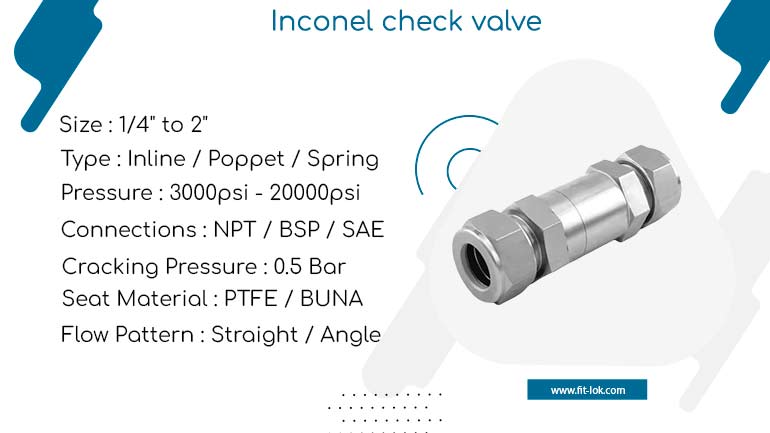

- Inconel check valve specification

- Alloy 625 check valve price list

- Various types of Inconel check valve

- Weight chart of Inconel 600 Check Valve

- Inconel hydraulic check valve chemical composition

- Inconel alloy Check valve mechanical properties

- Inconel instrument control check valve equivalent grade

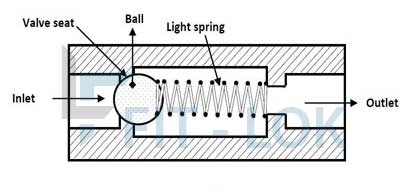

- Diagram of Inconel 600 Instrumentation Check Valve

- Incoloy 825 Threaded Check Valve Features

- Applications of Alloy 825 Non Return Check Valves

- DIN 2.4856 Instrumentation Check Valve standards

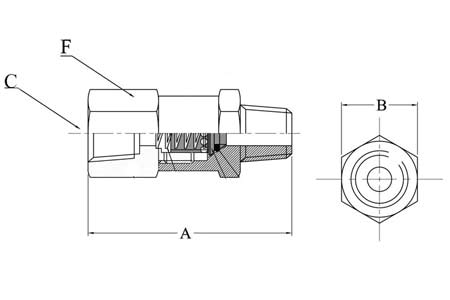

- Inconel 601 Male to Female check valve dimensions

- Pressure temperature rating of Inconel 625 Check Valve

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

Price of Nickel 600 NRV Valve vary between 15$ to 150$ per piece based on pressure rating, size, material, design and flow rate. For updated price list of DIN 2.4856 Spring Check Valve you can contact us on sales@fit-lok.com

Inconel Hydraulic Check Valve

Alloy 601 Inline Check Valve

Nickel 600 Nrv Valve

Inconel 625 Instrument Air Check Valve

Inconel 600 Non Return Valve

DIN 2.4856 Spring Check Valve

UNS N06625 Instrumentation Check Valve

Incoloy 825 Poppet Check Valve

Nickel 625 Instrument Control Valve

View sizes and dimensions of Incoloy 825 Threaded Check Valve and Inconel 625 Check Valve

| BW | lb | 44 | 33 | 51 | 113 | 93 | 149 |

| kg | 20 | 15 | 23 | 51 | 42 | 67 | |

| RF | lb | 444 | 289 | 667 | 1236 | 1002 | – |

| kg | 200 | 130 | 300 | 556 | 451 | – | |

| Size | IN | 10 | 8 | 12 | 16 | 14 | – |

| DN | 250 | 200 | 300 | 400 | 350 | – | |

| RF | lb | 53 | 42 | 62 | 140 | 107 | 176 |

| kg | 24 | 19 | 28 | 63 | 48 | 79 | |

| Size | IN | 2.5 | 2 | 3 | 5 | 4 | 6 |

| DN | 65 | 50 | 80 | 130 | 100 | 150 | |

| BW | lb | 360 | 262 | 524 | 1042 | 716 | – |

| kg | 162 | 118 | 236 | 469 | 322 | – |

| Grade | Ni | C | S | Mn | Si | Cu | Fe | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 72.00 min | 0.15 max | 0.015max | 1.00 max | 0.50 max | 0.50 max | 6.00 – 10.00 | 14.00 – 17.00 |

| Inconel 601 | 58.0 – 63.0 | 0.10 max | 0.015 max | 1.0 max | 0.5 max | 1.0 max | Balance | 21.0 – 25.0 |

| Inconel 625 | 58.0 min | 0.10 max | 0.015 max | 0.50 max | 0.50 max | – | 5.0 max | 20.0 – 23.0 |

| Inconel 718 | 50.00 – 55.00 | 0.08 max | 0.015 max | 0.35 max | 0.35 max | 0.30 max | – | 17.00 – 21.00 |

| Element | Elongation | Tensile Strength | Density | Melting Point | Yield Strength (0.2%Offset) |

|---|---|---|---|---|---|

| Inconel 600 | 40 % | Psi – 95,000 , MPa – 655 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 45,000 , MPa – 310 |

| Inconel 601 | 30 % | Psi – 80,000 , MPa – 550 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 30,000 , MPa – 205 |

| Inconel 625 | 42.5 % | Psi – 1,35,000 , MPa – 930 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 75,000 , MPa – 517 |

| Inconel 718 | 45 % | Psi – 1,35,000 , MPa – 930 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 75,000 , MPa – 482 |

| STANDARD | UNS | WNR | BS | JIS | EN | GOST | AFNOR |

| Inconel 600 | N06600 | 2.4816 | NA 13 | NCF 600 | NiCr15Fe | МНЖМц 28-2,5-1,5 | NC15FE11M |

| Inconel 601 | N06601 | 2.4851 | NA 49 | NCF 601 | NiCr23Fe | XH60BT | NC23FeA |

| Inconel 625 | N06625 | 2.4856 | NA 21 | NCF 625 | NiCr22Mo9Nb | ХН75МБТЮ | NC22DNB4M |

Alloy 825 Non Return Check Valves comes in various threads such as NPT, BSPP, BSPT and UNF thread

- Pressure and Temperature Resistance

- Durability

- Compact Design

- Versatility

- Ease of Maintenance

Inconel 600 foot valve widely used in pressure transmitters and pressure gauges

- Aerospace Industry

- Oil and Gas Industry

- Nuclear Power Plants

- Power Generation

- Chemical Processing

- Offshore Platforms

- Industrial Gas Systems

- DIN3352

- ASME B16.34

- ASME B16.5

- ASME B16.10

- ASME B16.25

- ASME B16.11

- BS 5352

- ASTM A494 / ASME SA494 API 602

- ASME B1.20.1

| A | B (A/F) | C | F (A/F) |

| 62 | 19 | 1/8″ | 19 |

| 62 | 19 | 1/4″ | 19 |

| 62 | 22 | 3/8″ | 22 |

| 75 | 28.5 | 1/2″ | 28.5 |

| 78 | 32 | 3/4″ | 32 |

| 90 | 41 | 1″ | 41 |

| Material | Alloy 625 | Alloy 825 |

|---|---|---|

| Temperature, °F (°C) | Working Pressure, psig (bar) | |

| –10 (–23) to 100 (37) | 6000 (413) | 6000 (413) |

| 200 (93) | 6000 (413) | 5510 (379) |

| 250 (121) | 6000 (413) | 5370 (369) |

| 300 (148) | 6000 (413) | 5225 (360) |

| 350 (176) | 5940 (409) | 5110 (352) |

| 400 (204) | 5880 (405) | 4995 (344) |