Top notch Manufacturer of Alloy 2507 hydraulic manifold valve in India

Refer Sizes and Dimensions of ASTM A182 S32750 manifold control valve

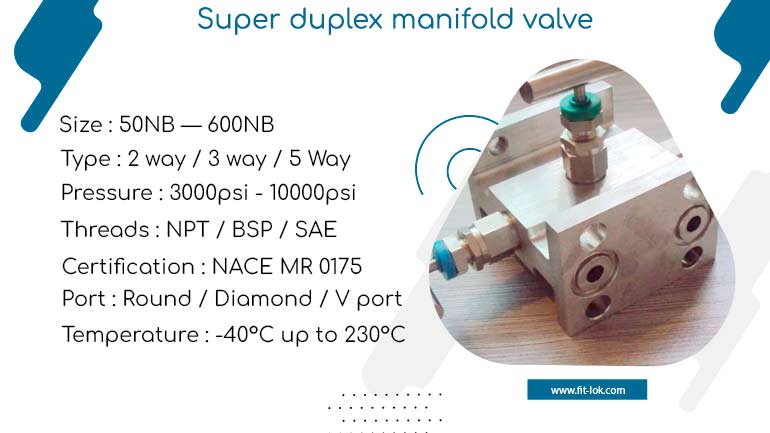

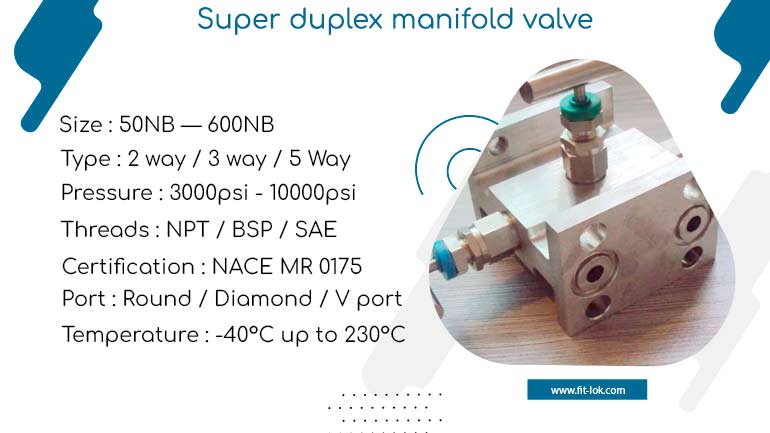

Super duplex manifold valve specification

| Type |

2 Way / 3 Way / 5 Way |

| Port Size |

1/4″ – 1/2″ |

| Pressure Rating |

Up to 6000 psi |

| End Connections |

NPT (female/male) / Flanged / Compression tube end |

| Threads |

NPT / BSP / SAE |

| Sealing |

PTFE / Graphite / PEEK |

| Surface Finish |

Electropolished / Passivated |

| Compliance |

ANSI B31.1 / NACE MR0175 / ISO 15156 |

| Temperature Rating |

−54°C to +538°C |

Alloy 2507 manifold control valve chemical composition

| C |

Si |

Mn |

S |

P |

Mo |

Cr |

Ni |

N |

Fe |

| 0.030 max |

0.80 max |

1.20 max |

0.020 max |

0.035 max |

3.00 – 5.00 |

24.00 – 26.00 |

6.00 – 8.00 |

0.24 – 0.32 |

58.095 min |

SAF 2507 manifold tuning valve Mechanical properties

| Tensile Strength, ksi |

Yield Strength, ksi Minimum |

Elongation Min. |

Hardness (HRB) |

| 116 |

80 |

15% |

310 |

Equivalent grade of Uns S32750 manifold valves

| Standard |

UNS |

WNR |

| Super Duplex 2507 |

S32750 |

1.4410 |

Pressure Rating Of Super duplex steel manifold valve

| Working Pressure |

up to 6,000 psi |

| Temperature Range |

–50 °C to +250 °C |

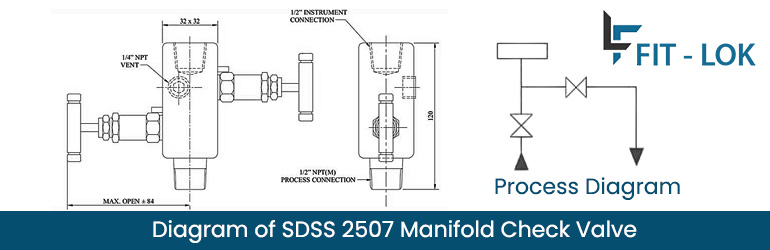

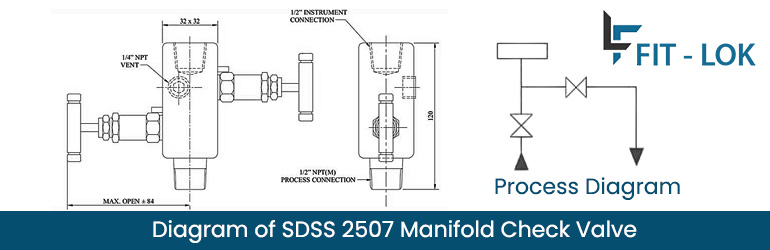

Diagram of SDSS 2507 manifold check valve

Dimension chart of super duplex manifold valve

| END CONNECTIONS |

DIMENSION |

| Process Connection |

Instrument Connection |

A |

B |

| 1/4″ FEMALE |

1/4″ MALE |

24 |

80 |

| 1/4″ FEMALE |

1/4″ FEMALE |

24 |

80 |

| 1/4″ MALE |

1/4″ MALE |

24 |

80 |

| 1/2″FEMALE |

1/2″ MALE |

30 |

115 |

| 1/2″ MALE |

1/2″FEMALE |

30 |

115 |

| 1/2″ MALE |

1/2″ MALE |

30 |

115 |

| 3/4″ FEMALE |

1/2″ MALE |

30 |

115 |

| 1/2″ MALE |

3/4″ FEMALE |

38 |

115 |

| 3/4″ FEMALE |

3/4″ MALE |

38 |

115 |

| 3/4″ FEMALE |

3/4″ FEMALE |

38 |

115 |

| 3/4″ MALE |

3/4″ MALE |

38 |

115 |

Function of Alloy 2205 3 Way Manifold Valve

- High strength

- Excellent corrosion resistance

- Good fatigue and erosion resistance

- Long service life

Why choose Fit-lok for to buy 25cr duplex Manifold Control Valve?

SDSS 2507 Instrument Manifold Valve Application

- Oil & Gas Industry

- Petrochemical Plants

- Desalination Plants

- Power Generation

- Pulp & Paper Industry

- Chemical Industry

Alloy 2507 Hydraulic Manifold Valve Physical Properties

| Density |

7.8 g/cm3 |

| Melting point |

1350°C |