A long established manufacturer of Cu-ni 90/10 hydraulic manifold valve in India

Refer latest price list and dimensions of Cupro nickel 5 way manifold valve

Table of content

- What Is Copper Nickel Manifold Valve?

- Copper nickel manifold valve specification

- Cupro nickel manifold control valve chemical composition

- Cuni manifold tuning valve Mechanical properties

- Equivalent grade of Copper nickel manifold valves

- Pressure Rating Of Copper nickel 90/10 manifold valve

- Size Chart of Cupro nickel 70/30 manifold check valve

- CuNi 90/10 Pneumatic Manifold Block physical properties

- Classification of Cupro Nickel 5 Way Manifold Valve

- Advantages of DIN 2.0882 Instrument Manifold Valve

- UNS C71500 Hydraulic Manifold Valve application

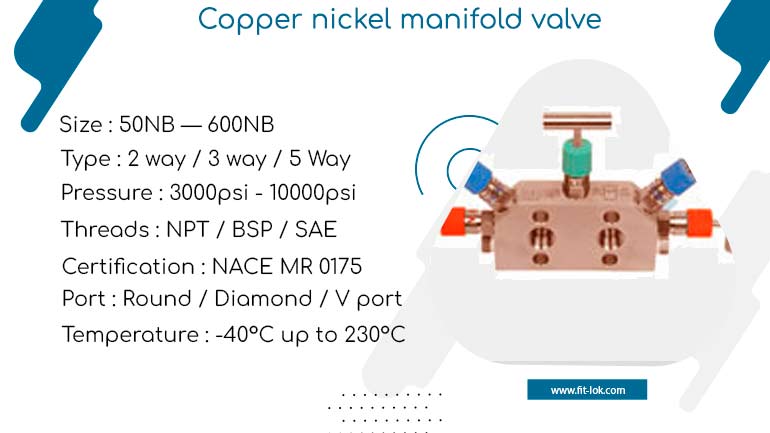

Copper nickel manifold valves are designed to control, isolate and bleed fluids in corrosive environments. These valves have excellent corrosion resistance properties against seawater, brine, and chloride solutions. Cuni Manifold valves are comes in 2 Way, 3 Way and 5 Way configuration.

| Size Range | 1/8″ to 1″ |

|---|---|

| Valve Types | 2-way / 3-way / 5-way |

| Body Materials | Bar Stock / Forged |

| Connection Types | NPT / BSPT / BSPP |

| Pressure Ratings | Up to 15,000 psi |

| Standards | ASME B16.34 / MSS SP-99 / ISO 15156 |

| Sealing | Graphite / PTFE / PEEK |

| Bonnet Type | Screwed bonnet / Union bonnet |

| Temperature Range | -50 °C to +300 °C |

| Mounting | Direct / Remote mounting |

| Surface Finish | Electropolished / passivated |

| Documentation | EN 10204 Type 3.1 MTC / Material certificates / NDT reports |

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cu Ni 90/10 | 88.6 min | 1.0 max | .05 max | 9-11 max | 1.8 max | 1 max |

| Cu Ni 70/30 | 65.0 min | 1 max | .05 max | 29-33 | 0.4-1.0 | 1 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

| STANDARD | WNR | UNS |

| Copper Nickel 90/10 | 2.0872 | C70600 |

| Copper Nickel 70/30 | 2.0882 | C71500 |

| Valve Size / Material | Max Working Pressure |

|---|---|

| 1/4″ – 1″ 90/10 Cu-Ni | 3000–4000 psi (200–275 bar) |

| 1/4″ – 1″ 70/30 Cu-Ni | 4000–5000 psi (275–345 bar) |

| Temp Derating | Pressure decreases ~10–20% at 200–300 °C |

| Connections | C | End Connection | LG | THK | Top/Bottom Connection | Width |

|---|---|---|---|---|---|---|

| 4 | 1.38 | HF9 | 5.26 | 1.5 | HF6 | 2.63 |

| 6 | 1.38 | HF9 | 7.76 | 1.5 | HF6 | 2.63 |

| 8 | 1.38 | HF9 | 10.26 | 1.5 | HF6 | 2.63 |

| 10 | 1.38 | HF9 | 12.76 | 1.5 | HF6 | 2.63 |

| 14 | 1.38 | HF9 | 17.76 | 1.5 | HF6 | 2.63 |

| Density | Elastic modulus | Poisson’s ratio | Shear modulus | Thermal conductivity |

|---|---|---|---|---|

| 8.94 g/cm3 | 117 GPa | 0.34 | 52 GPa | 36 W/mK |

| Copper Nickel 2-way Manifold Valve | 2-way T Type 2-way R Type |

|---|---|

| Cupro Nickel 3-way Manifold Valve | 3-way T Type 3-way R Type 3-way H Type |

| CuNi 5-way Manifold Valve | 5-way T Type 5-way R Type 5-way H Type |

- Excellent corrosion resistance

- Non magnetic

- Good thermal conductivity

- Erosion resistant

- Medium pressure suitability

- Easy fabrication and welding