Contact us if you are looking for Titanium grade 2 instrument solenoid valve manufacturer in India

Top notch Supplier of Ti grade 5 instrumentation manifolds

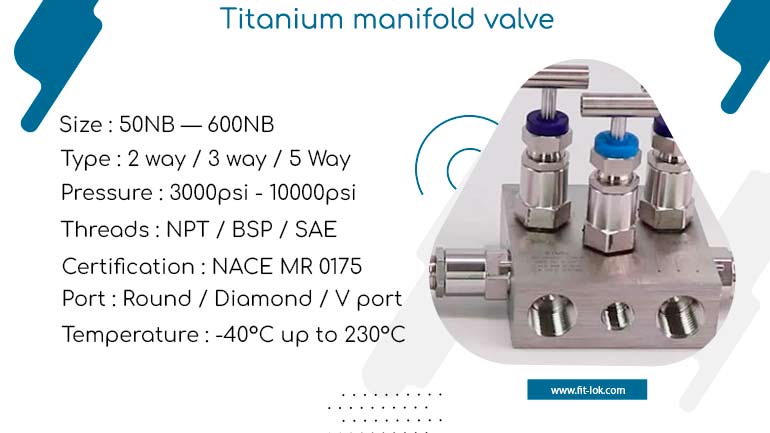

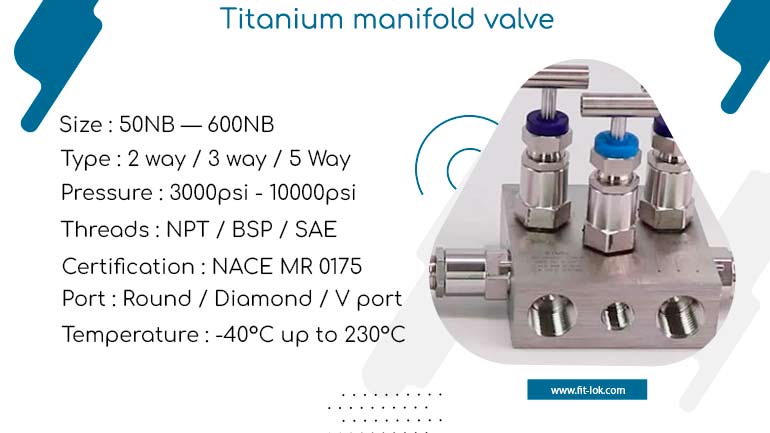

Titanium manifold valve specification

| Size Range |

1/8″ to 1″ |

| Valve Types |

2-way / 3-way / 5-way |

| Pressure Ratings |

Up to 15,000 psi |

| Body Materials |

Bar Stock / Forged |

| Connection Types |

NPT / BSPT / BSPP |

| Standards |

ASME B16.10 / API 598 / ASME B16.34 |

| Sealing |

Graphite / PTFE / PEEK |

| Bonnet Type |

Screwed bonnet / Union bonnet |

| Temperature Range |

-200 °C to +400 °C |

| Mounting |

Direct / Remote mounting |

| Surface Finish |

Electropolished / passivated |

| Hardness |

160–200 HB |

Titanium manifold control valve chemical composition

| Grade |

Ti |

C |

Fe |

H |

N |

O |

Al |

V |

| Ti Grade2 |

99.2 min |

0.1 max |

0.3 max |

0.015 max |

0.03 max |

0.25 max |

– |

– |

| Ti Grade5 |

90 min |

– |

0.25 max |

– |

– |

0.2 max |

6 min |

4 min |

Titanium alloy manifold tuning valve Mechanical properties

| Element |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| Titanium Gr. 2 |

Psi – 49900 , MPa – 344 |

Psi – 39900 , MPa – 275 |

20 % |

| Titanium Gr. 5 |

Psi – 138000 , MPa – 950 |

Psi – 128000 , MPa – 880 |

14 % |

Equivalent grade of Titanium manifold valves

| STANDARD |

WERKSTOFF NR. |

UNS |

| Titanium Gr. 2 |

3.7035 |

R50400 |

| Titanium Gr. 5 |

3.7165 |

N56400 |

Pressure Rating Of Titanium grade 2 manifold valve

| Valve Rating |

Material |

Max Working Pressure (at 25 °C) |

Max Temp |

| Class 1500 |

Titanium Grade 2 |

~6000 psi (414 bar) |

400 °C |

| Class 2500 |

Titanium Grade 5 |

~10,000 psi (690 bar) |

500 °C |

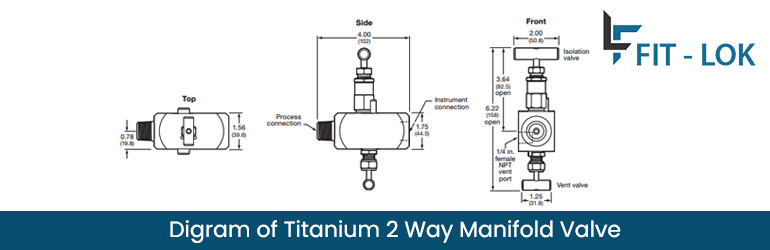

Size Chart of Alloy gr 5 manifold check valve

| END CONNECTIONS |

DIMENSION |

| Instrument Connection |

Process Connection |

B |

A |

| 1/4″ MALE |

1/4″ FEMALE |

80 |

24 |

| 1/4″ FEMALE |

1/4″ FEMALE |

80 |

24 |

| 1/4″ MALE |

1/4″ MALE |

80 |

24 |

| 1/2″ MALE |

1/2″FEMALE |

115 |

30 |

| 1/2″FEMALE |

1/2″ MALE |

115 |

30 |

| 1/2″ MALE |

1/2″ MALE |

115 |

30 |

| 1/2″ MALE |

3/4″ FEMALE |

115 |

30 |

| 3/4″ FEMALE |

1/2″ MALE |

115 |

38 |

| 3/4″ MALE |

3/4″ FEMALE |

115 |

38 |

| 3/4″ FEMALE |

3/4″ FEMALE |

115 |

38 |

| 3/4″ MALE |

3/4″ MALE |

115 |

38 |

Ti alloy manifold valve Manufacturing standard

| End Connection |

ASME B 16.5- Flanged End

ASME B 16.25- Butt Weld End |

| Testing |

BS EN 12266 – 1 |

| Face To Face |

ASME B 16.10 |

| Pressure – Temperature Chart |

ASME B 16.34 |

| Design |

BS 1868 |

Advantages of DIN 3.7035 5 Way Manifold Valve

- 5 way configuration

- Compact Design

- Ease of Operation

- Leak Tightness

- High Temperature Compatibility

- Reduced Installation Time

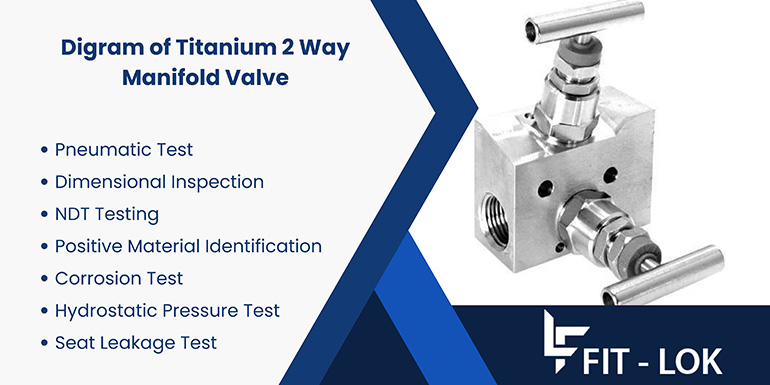

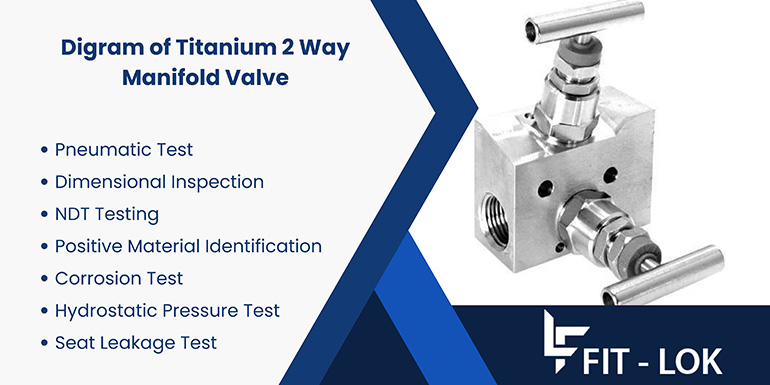

Ti gr 5 Manifold Control Valve material testing

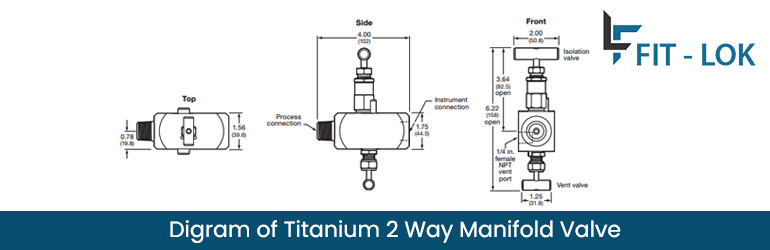

Digram of Titanium 2 Way Manifold Valve

Forging temperature of UNS R56400 Pneumatic Manifold Block

| Forging temperature |

899°C (1650°F) |

Titanium grade 5 Manifold Valve physical properties

| Density |

4.51 g/cm3 |

| Melting point |

1660°C |

| Poisson’s ratio |

0.34-0.40 |

| Elastic modulus |

105 – 120 GPa |

| Thermal conductivity |

21.97 W/mK |