Leading Alloy C276 manifold heat control valve Manufacturer in India

Check available sizes of Hastelloy C22 manifold valve

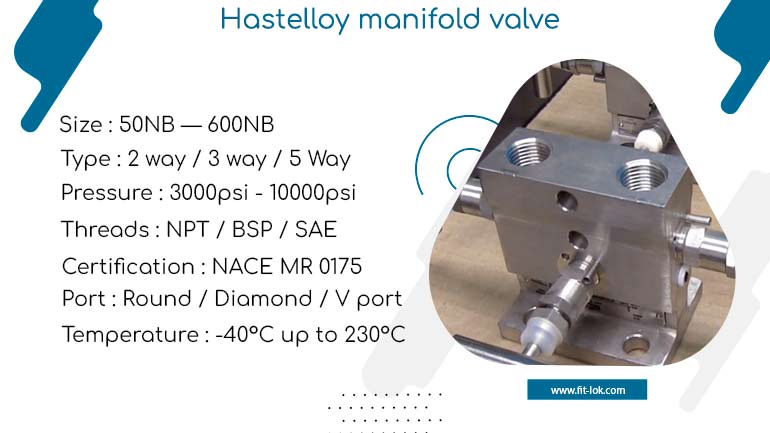

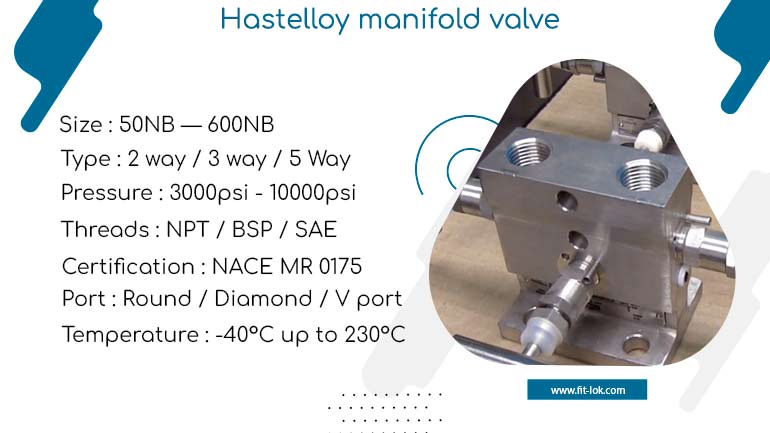

Hastelloy manifold valve specification

| Type |

2 Way / 3 Way / 5 Way |

| Pressure Rating |

Up to 6000 psi |

| Port Size |

1/4″ – 1/2″ |

| Threads |

NPT / BSP / SAE |

| End Connections |

NPT (female/male) / Flanged / Compression tube end |

| Sealing |

PTFE / Graphite / PEEK |

| Compliance |

ANSI B31.1 / NACE MR0175 / ISO 15156 |

| Surface Finish |

Electropolished / Passivated |

| Temperature Rating |

−54°C to +538°C |

Hastelloy manifold control valve chemical composition

| Grade |

C |

Mn |

Si |

S |

Co |

Ni |

Cr |

Fe |

Mo |

P |

| C276 |

0.010 max |

1.00 max |

0.08 max |

0.03 max |

2.50 max |

50.99 min* |

14.50 – 16.50 |

4.00 – 7.00 |

15.00 – 17.00 |

0.04 max |

| C22 |

0.010 max |

0.50 max |

0.08 max |

0.02 max |

2.50 max |

50.015 min* |

20.00 – 22.50 |

2.00 – 6.00 |

12.50 – 14.50 |

0.02 max |

| B2 |

0.02 max |

1.0 max |

0.1 max |

0.03 max |

1.0 max |

Bal |

1.0 max |

2.0 max |

26 – 30 |

0.04 max |

Hastelloy alloy manifold tuning valve Mechanical properties

| Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| Hastelloy C276 |

8.89 g/cm3 |

1370 °C (2500 °F) |

Psi – 1,15,000 , MPa – 790 |

Psi – 52,000 , MPa – 355 |

40 % |

| Hastelloy C22 |

8.69 g/cm3 |

1399 °C (2550 °F) |

Psi – 1,00,000 , MPa – 690 |

Psi – 45000 , MPa – 310 |

45 % |

| Hastelloy B2 |

9.2 g/cm3 |

1370 °C (2500 ºF ) |

Psi – 1,10,000 , MPa – 760 |

Psi – 51000 , MPa – 350 |

40 % |

Equivalent grade of Hastelloy manifold valves

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

GOST |

EN |

OR |

| Hastelloy C276 |

2.4819 |

N10276 |

NW 0276 |

ХН65МВУ |

NiMo16Cr15W |

ЭП760 |

| Hastelloy C22 |

2.4602 |

N06022 |

NW 6022 |

– |

NiCr21Mo14W |

– |

| Hastelloy B2 |

2.4617 |

N10665 |

– |

– |

– |

– |

Pressure Rating Of Hastelloy C276 manifold valve

| Operating pressure |

Max.: 700 bar (10,153 psi) |

Size Chart of Alloy C22 manifold check valve

| END CONNECTIONS |

DIMENSION |

| Instrument Connection |

Process Connection |

B |

A |

| 1/4″ MALE |

1/4″ FEMALE |

80 |

24 |

| 1/4″ FEMALE |

1/4″ FEMALE |

80 |

24 |

| 1/4″ MALE |

1/4″ MALE |

80 |

24 |

| 1/2″ MALE |

1/2″FEMALE |

115 |

30 |

| 1/2″FEMALE |

1/2″ MALE |

115 |

30 |

| 1/2″ MALE |

1/2″ MALE |

115 |

30 |

| 1/2″ MALE |

3/4″ FEMALE |

115 |

30 |

| 3/4″ FEMALE |

1/2″ MALE |

115 |

38 |

| 3/4″ MALE |

3/4″ FEMALE |

115 |

38 |

| 3/4″ FEMALE |

3/4″ FEMALE |

115 |

38 |

| 3/4″ MALE |

3/4″ MALE |

115 |

38 |

Documentation requirements of Hastelloy manifold valve

Testing of Hastelloy C276 Hydraulic Manifold Valve

- Hydrostatic Pressure Test

- Seat Leakage Test

- Pneumatic Test

- Dimensional Inspection

- Corrosion Test

- Positive Material Identification

- NDT Testing

Corrosion Resistant of Ni C22 Instrument Manifold Valve

| Media |

Property |

| Acid Resistance |

Outstanding in:

Hydrochloric acid (HCl)

Sulfuric acid (H₂SO₄)

Nitric acid (HNO₃)

Phosphoric acid (H₃PO₄) |

| Oxidizing Agents |

Resists wet chlorine, hypochlorites |

| Sea Water |

Excellent resistance to corrosion in marine enviroments |

Physical property of Hastelloy C276 manifold valve

| Density |

8.89 g/cm³ |

| Melting point |

1371°C |

| Thermal conductivity |

7.20 W/mK |

| Elastic modulus |

205 GPa |

Alloy C276 3 Way Manifold Valve Heat Treatment

| Heat Treatment |

1121°C (2050°F) |