We are top notch Duplex 2205 hydraulic ball valve Manufacturer in India

Call us to get latest stock and price list of Duplex steel ball valve

Table of content

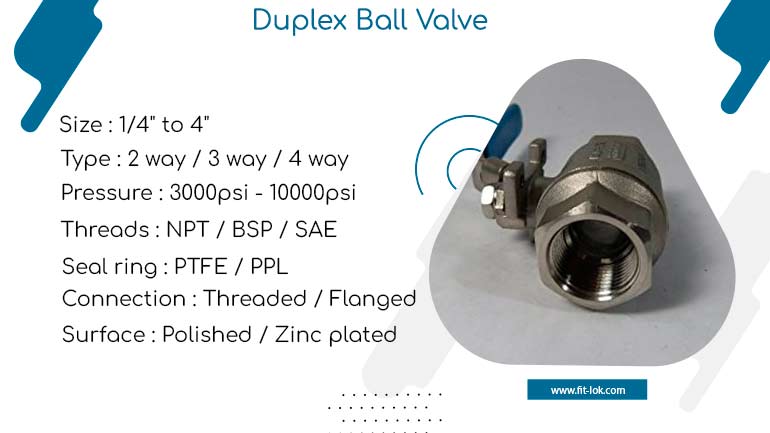

- Duplex ball valve specification

- Duplex 2205 instrumentation ball valve chemical composition

- SAF 2205 Panel Mounted Ball Valve Mechanical properties

- Equivalent grade of UNS S31803 ball valves

- Pressure Rating Of DSS 2205 ball valve

- Leakage rate of Duplex steel 3 way ball valve

- Duplex ball valves types

- Pressure & Temperature Limit of 22cr duplex Cryogenic Ball Valves

- Alloy 2205 Ferrule Ball Valve application

- Corrosion Resistance Characteristics of DIN 1.4462 ball valve

- 2205 duplex Compression Ball Valves documents requirement

| Size | 1/4″ to 4″ |

| Valve Type | 2 Way / 3 Way |

| Standards | ASME B16.34 / API 608 / ISO 17292 |

| Pressure Rating | 3000 PSI / 6000 PSI / 10000 PSI / 15000 PSI |

| Bore Type | Full Bore / Reduced Bore |

| End Connections | Female / Male NPT / Socket Weld / Double Ferrule Compression |

| Flow Rate | .93, 2.34, 6.42, .70, 1.04, 3.62,.87 Cv |

| Surface Finish | Machined / Pickled / Electropolished |

| Fire Safe Design | API 607 / ISO 10497 |

| Approvals |

|

| C | Ni | N | Mn | Cr | P | Si | Mo | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.030 max | 4.50 – 6.50 | 0.14 – 0.20 | 2.00 max | 22.0 – 23.0 | 0.030 max | 1.00 max | 3.0 – 3.5 | 0.020 max | 63.72 min |

| Yield Strngth (Mpa) | 450 |

|---|---|

| Elongation % | 25 min. |

| Tensile Strength (Mpa) | 655 |

| Hardness (Brinell) | 293 max |

| Standard | UNS | WNR |

|---|---|---|

| Duplex 2205 | S31803 | 1.4462 |

| NPS | Pressure Rating (PSIG) |

|---|---|

| 1-1/2″ | 1000 PSIG |

| 2 | 800 PSIG |

| 3 | 600 PSIG |

| 4 – 5 | 500 PSIG |

| 6 | 300 PSIG |

| Soft Seal | zero leakage, 100% Leak test |

| Hard Seal | Rated Flow ≤ 10-5 |

Duplex 2205 Hydraulic Ball Valves

UNS S31803 High Pressure Ball Valves

SAF 2205 Cryogenic Ball Valves

DIN 1.4462 Compression Ball Valves

Duplex steel Instrument Ball Valve

Alloy 2205 Flow Control Ball Valves

| Class | Pressure Rating |

|---|---|

| Class 1500 | 3600 psig/248 bar |

| Class 2500 | 6000 psig/414 bar |

| Class 4500 | 10000 psig/689 bar |

- High resistance to stress corrosion cracking

- Good sulfide stress corrosion resistance

- High energy absorption

- Blow out proof stem

- Anti leakage packing

- Mill Test Certificates

- Material Traceability Record

- Dimensional Inspection Report

- Surface Finish Report

- Hydrostatic Test Certificate

- Seat Leak Test Report

- Certificate of Conformity

- Manufacturer’s Test Certificate