Stainless Steel SAE Industrial Flanges manufacturer in India

Buy ASTM A105 SAE Zako Flanges directly from supplier in Mumbai

Table of content

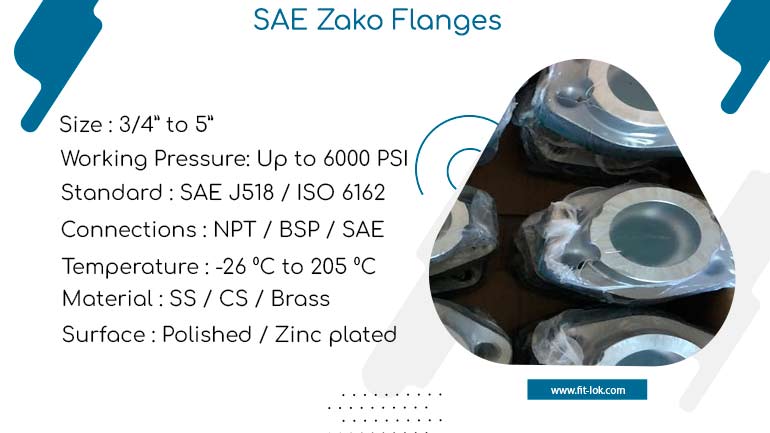

| Type | SAE Zako Flanges |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE Zako Flanges

Stainless Steel SAE Industrial Flanges

ASTM A105 SAE Zako Flanges

| Pipe OD* (mm) | Wall thickness (mm) |

|---|---|

| 16 | 2,0 | 2.5 |

| 20 | 3,0 | 2,5 | 3,0 | 3,5 |

| 25 | 3,0 | 4.0 |

| 38 | 4,0 | 5,0 | 6,0 |

| 42 | 2.0 |

| 50 | 2,5 | 5,0 | 6,0 | 8,0 | 9,0 |

| 60 | 2,0 | 5,0 | 10,0 |

| 65 | 3,0 | 4,0 | 5,0 | 8,0 |

| 75 | 12.5 |

| 80 | 3,0 | 8,0 | 10,0 |

| 88 | 14.0 |

| 101.6 | 16.0 |

| 114.3 | 17.5 |

| 120 | 20.0 |

| Product | Price in USD (Pcs) |

Price in Dirham (Pcs) |

Price in Euro (Pcs) |

|---|---|---|---|

| 2″ SAE Zako Flange, 6000 PSI | US $16.82 | 61.77 AED | € 14.56 |

| 1 1/4″ SAE Zako Flange, 6000 PSI | US $10.27 | 37.72 AED | € 8.89 |

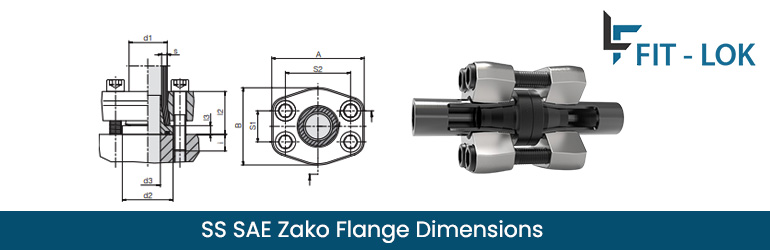

| Tube d1 x s |

Fl. size |

d3 | d2 | l3 | l2 ca. |

S2 | S1 | B | A | i ca. |

4 x cyl. screws |

Nm | kg/100 ca. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 x 2 | 1/2″ | 10.5 | 30 | 8 | 32 | 38.1 | 17.5 | 48 | 56 | 13 | M 8 x 45 | 35 | 43.9 |

| 16 x 2,5 | 1/2″ | 9.5 | 30 | 8 | 32 | 38.1 | 17.5 | 48 | 56 | 13 | M 8 x 45 | 35 | 43.9 |

| 16 x 3 | 1/2″ | 8.5 | 30 | 8 | 32 | 38.1 | 17.5 | 48 | 56 | 13 | M 8 x 45 | 35 | 43.9 |

| 20 x 2,5 | 3/4″ | 13.5 | 38 | 8 | 32 | 47.6 | 22.2 | 52 | 65 | 13 | M 10 x 45 | 69 | 54.7 |

| 20 x 3 | 3/4″ | 12.5 | 38 | 8 | 32 | 47.6 | 22.2 | 52 | 65 | 13 | M 10 x 45 | 69 | 54.8 |

| 25 x 3 | 3/4″ | 17 | 38 | 8.5 | 32.5 | 47.6 | 22.2 | 52 | 65 | 12.5 | M 10 x 45 | 69 | 66.9 |

| 25 x 4 | 3/4″ | 15 | 38 | 8.5 | 32.5 | 47.6 | 22.2 | 50 | 65 | 12.5 | M 10 x 45 | 69 | 66.9 |

| 30 x 4 | 1″ | 20 | 46 | 8.5 | 42.5 | 52.4 | 26.2 | 60 | 72 | 12.5 | M 10 x 55 | 69 | 80.1 |

| 30 x 5 | 1″ | 17 | 46 | 8.5 | 42.5 | 52.4 | 26.2 | 60 | 72 | 12.5 | M 10 x 55 | 69 | 81.3 |

| 38 x 4 | 1 1/4″ | 28 | 52 | 9 | 44 | 58.7 | 30.2 | 73 | 79 | 16 | M 12 x 60 | 120 | 106.7 |

| 38 x 5 | 1 1/4″ | 56 | 52 | 9 | 44 | 58.7 | 30.2 | 73 | 79 | 16 | M 12 x 60 | 120 | 107.2 |

| 38 x 6 | 1 1/4″ | 23 | 52 | 9 | 44 | 58.7 | 30.2 | 73 | 79 | 16 | M 12 x 60 | 120 | 107.3 |

| 42 x 2 | 1 1/4″ | 34 | 52 | 9 | 44 | 58.7 | 30.2 | 73 | 79 | 16 | M 10 x 60 | 69 | 80.1 |

| 50 x 2,5 | 1 1/2″ | 42 | 63 | 10 | 46 | 69.9 | 35.7 | 83 | 94 | 14 | M 12 x 60 | 120 | 136.3 |

| 50 x 5 | 1 1/2″ | 37 | 63 | 10 | 46 | 69.9 | 35.7 | 83 | 94 | 14 | M 12 x 60 | 120 | 136.9 |

| 50 x 6 | 1 1/2″ | 35 | 63 | 10 | 46 | 69.9 | 35.7 | 83 | 94 | 14 | M 12 x 60 | 120 | 136.8 |

| 50 x 8 | 1 1/2″ | 31 | 63 | 10 | 46 | 69.9 | 35.7 | 83 | 94 | 14 | M 12 x 60 | 120 | 140 |

| 65 x 3 | 2″ | 55 | 75 | 11 | 60 | 77.8 | 42.9 | 97 | 102 | 15 | M 12 x 75 | 120 | 189 |

| 65 x 4 | 2″ | 54 | 75 | 11 | 60 | 77.8 | 42.9 | 97 | 102 | 15 | M 12 x 75 | 120 | 183 |

| 65 x 5 | 2″ | 52 | 75 | 11 | 60 | 77.8 | 42.9 | 97 | 102 | 15 | M 12 x 75 | 120 | 186.3 |

| 80 x 3 | 3″ | 71 | 100 | 16 | 66 | 106.4 | 61.9 | 131 | 135 | 24 | M 16 x 90 | 295 | 405.6 |

| Standard series | up to 250 bar |

|---|---|

| High pressure series | up to 400 bar |

| Connection Type | Pressure Capability |

|---|---|

| Flared Tube | Up to Code 62 |

| Welded Flare | Very high |

| O-Ring Face Seal | Up to Code 62 |

| Threaded Flared | Lower than welded/flanged |