Leading 3000 PSI 90 deg buttweld flange manufacturer in India

Table of content

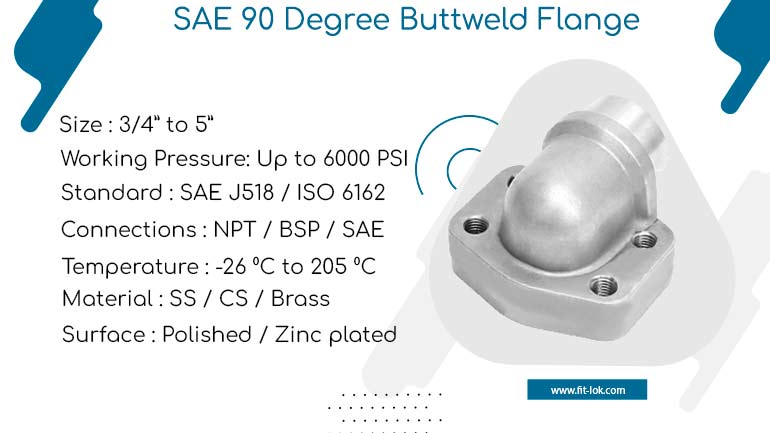

- SAE 90 degree buttweld flange Specification

- Different types of SAE 90 deg buttweld flange

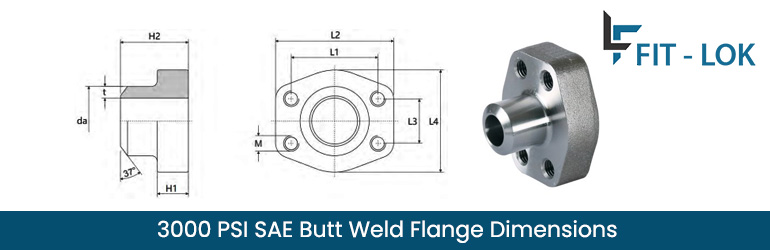

- 3000 PSI SAE Butt Weld Flange Dimensions

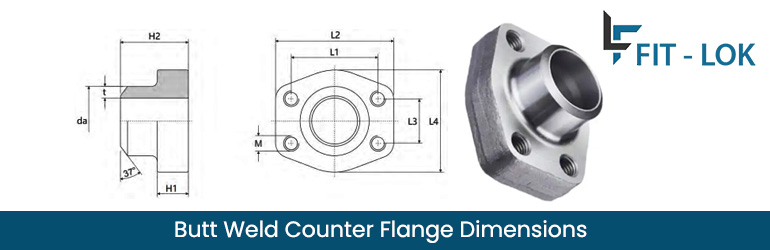

- Butt Weld Counter Flange Dimensions

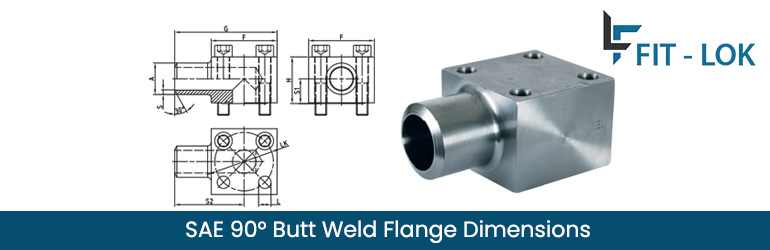

- SAE 90°Butt Weld Flange Dimensions

- SAE 90 degree buttweld flange Price list

- Features of 3000 PSI 90 deg buttweld flange

- Stainless steel 90 deg buttweld flange Application

| Type | SAE 90 degree buttweld flange |

| DESIGN | SAE J518 C / ISO 6162 / ISO 6164 / JIS B2291 |

| MATERIAL | CS, SS 304, SS 316, SS 316 TI, ALLOY STEEL, DUPLEX, SUPER DUPLEX, INCONEL, MONEL, HASTELLOY, SMO 254, 904 L, TITANIUM |

| WORKING PRESSURE | UPTO 210 BAR (3000 PSI) & 420 BAR (6000 PSI) & 700 BAR (10,000 PSI) CUSTOMISED |

| CODE | CODE 61 FLANGE (3000 PSI) & CODE 62 FLANGE (6000 PSI) |

| SIZE RANGE | 3/8″ (DN 10) TO 5″ (DN 125) |

| CONNECTIONS | BUTT WELD, SOCKET WELD, THREADED (BSPP, NPT, METRIC, JIC) |

| BODY TYPE | FORGED, BAR STOCK |

| FLANGE ACCESSORIES | O-RING, BOLT, NUT, WASHER |

| O-RING MATERAL | NITRILE, BUNA 90 SHORE, VITON 85-90 SHORE |

| BOLTS MATERIAL | HIGH TENSILE 8.8 GR, 10.9 GR, 12.9 GR, SS 304, SS316 |

| SURFACE | CARBON STEEL – BLACK PHOSPHATED, TRIVALENT ZINC PLATED, |

| STAINLESS STEEL – ELECTROPLATING, NATURAL FINISH |

SAE 90 degree buttweld flange

3000 PSI 90 deg buttweld flange

Stainless steel 90 deg buttweld flange

| Size Inch |

Dimensions(mm) | Accessories | Pressure Bar |

Weight Kg |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| da×t | L3 | L2 | L4 | L1 | H2 | H1 | D | O-Ring | Bolt | |||

| 1/2 | 16×2.5 20×3 21.6×4.3 |

17.5 | 54 | 46 | 38.1 | 36 | 16 | 9 | 18.66×3.53 | M8×30 | 345 | 0.28 |

| 3/4 | 25×3 26.9×3.6 28×4.5 |

22.26 | 65 | 50 | 47.63 | 36 | 18 | 11 | 25.00×3.53 | M10×35 | 345 | 0.39 |

| 1 | 30×4 33.7×3.6 34×4.5/3 5×4 |

26.16 | 70 | 55 | 52.37 | 38 | 18 | 11 | 32.92×3.53 | M10×35 | 345 | 0.46 |

| 1 1/4 | 38×4 42.4×3.6 42.8×5.5 |

30.18 | 79 | 68 | 58.72 | 41 | 21 | 11.5 | 37.70×3.53 | M10×40 | 276 | 0.66 |

| 1 1/2 | 42.2×4 48.3×4 48.6×5.5 |

35.72 | 93 | 78 | 69.85 | 45 | 25 | 13.5 | 47.22×3.53 | M12×45 | 207 | 1.05 |

| 2 | 60.3×4 61×5.5 |

42.88 | 102 | 90 | 77.77 | 45 | 25 | 13.5 | 56.75×3.53 | M12×45 | 207 | 1.09 |

| 2 1/2 | 76.1×4 77×7.1 |

50.8 | 114 | 105 | 88.9 | 50 | 25 | 13.5 | 69.45×3.53 | M12×45 | 172 | 1.4 |

| 3 | 76.1×4 76.1×7.1 89×4 92×9 |

61.92 | 135 | 124 | 106.4 | 50 | 27 | 17 | 85.32×3.53 | M16×50 | 138 | 2.15 |

| 3 1/2 | 89×4 103×7 |

69.85 | 152 | 136 | 120.7 | 48 | 27 | 17 | 98.02×3.53 | M16×50 | 34 | 2.4 |

| 4 | 114.3×4 115.5×8 |

77.76 | 162 | 146 | 130.2 | 48 | 27 | 17 | 110.72×3.53 | M16×50 | 34 | 2.85 |

| Size Inch |

Dimensions(mm) | Pressure Bar |

Weight Kg |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|

| da×t | L3 | L2 | L4 | L1 | H2 | H1 | M | |||

| 1/2 | 16×2.5 20×3 21.6×4.3 |

17.5 | 54 | 46 | 38.1 | 36 | 16 | M8 | 345 | 0.28 |

| 3/4 | 25×3 26.9×3.6 28×4.5 |

22.26 | 65 | 50 | 47.63 | 36 | 18 | M10 | 345 | 0.39 |

| 1 | 30×4 33.7×3.6 34×4.5 35×4 |

26.16 | 70 | 55 | 52.37 | 38 | 18 | M10 | 345 | 0.46 |

| 1 1/4 | 38×4 42.4×3.6 42.8×5.5 |

30.18 | 79 | 68 | 58.72 | 41 | 21 | M10 | 276 | 0.66 |

| 1 1/2 | 42.2×4 48.3×4 48.6×5.5 |

35.72 | 93 | 78 | 69.85 | 45 | 25 | M12 | 207 | 1.05 |

| 2 | 60.3×4 61×5.5 |

42.88 | 102 | 90 | 77.77 | 45 | 25 | M12 | 207 | 1.09 |

| 2 1/2 | 76.1×5.5 77×7.1 |

50.8 | 114 | 105 | 88.9 | 50 | 25 | M12 | 172 | 1.4 |

| 3 | 76.1×4 76.1×7.1 89×4 92×9 |

61.92 | 135 | 124 | 106.4 | 50 | 27 | M16 | 138 | 2.15 |

| 3 1/2 | 89×4 103×7 |

69.85 | 152 | 136 | 120.7 | 48 | 27 | M16 | 34 | 2.4 |

| 4 | 114.3×4 115.5×8 |

77.76 | 162 | 146 | 130.2 | 48 | 27 | M16 | 34 | 2.85 |

| DN | Dimensions | Weight | Bolts | O-Ring | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A x S | S2 | S1 | LK | F | L | G | H | kg | M | ||

| 10 | 17,2×3,6 | 55 | 17 | 44 | 50 | 11 | 80 | 29 | – | 4/M10x40 | 16,3 x 2,40 |

| 16 | 21,3×2,6 | 65 | 23 | 54 | 60 | 11 | 95 | 41 | – | 4/M10x45 | 25,3 x 2,40 |

| 20 | 26,9×3,6 | 75 | 26 | 64 | 70 | 13 | 110 | 47 | – | 4/M12x60 | 29,8 x 2,60 |

| 25 | 33,7×4,5 | 90 | 30 | 72 | 80 | 13 | 130 | 56 | – | 4/M12x65 | 34,5 x 2,60 |

| 32 | 42,4×5,6 | 95 | 35 | 80 | 90 | 17 | 140 | 64 | 3.2 | 4/M16x80 | 43,0 x 3,00 |

| 40 | 60,3×8 ; 60,3×10 | 105 | 40 | 98 | 100 | 17 | 155 | 76 | 4,9/5,1 | 4/M16x100 | 53,3 x 5,33 |

| 50 | 76,1×10 ; 76,1×12,5 | 115 | 53 | 118 | 120 | 22 | 175 | 100 | 8,2/9,1 | 4/M20x125 | 61,0 x 5,00 |

| 65 | 88,9×11 ; 88,9×14,2 | 125 | 64 | 145 | 150 | 25 | 200 | 120 | 16,1/16,8 | 4/M24x150 | 75,0 x 5,00 |

| 80 | 114,3×12,5 101,6×14,2 ; 114,3×17,5 |

130 | 73 | 175 | 180 | 32 | 220 | 140 | 24,9 26,3/26,8 |

4/M30x180 | 88,0 x 6,00 |

| Product | Price in USD (Pcs) |

Price in Dirham (Pcs) |

Price in Euro (Pcs) |

|---|---|---|---|

| 1/2″ Carbon Steel SAE 90 deg Buttweld Flange | US $13.58 | 49.87 AED | € 11.68 |

| 3/4″ SS SAE 90 Deg Buttweld Falnge, 3000 PSI | US $16.29 | 59.83 AED | € 14.01 |

- Industrial Hydraulics

- Steel Mills

- Hydraulic Presses

- Injection Moulding Machinery

- Aluminium Die-Casting Machinery

- Sintering Machinery