One of the leading ASTM A249 Type 304 ERW Tubing Supplier in India

Check Welded 304 Stainless Steel Tubing Dimensions & Weight charts

Table of content

- Specification List of Stainless Steel Welded Tube

- Different types of A249 Stainless Steel Pressure Tube

- Chemical composition of SS ERW Tube

- Mechanical properties of SS Welded Tube

- Equivalent grade of Stainless Steel Welded Tubing

- Wall Thickness Tolerance of ASTM A249 Type 304 ERW Tubing

- Dimensions of 304 Stainless Steel Tubing

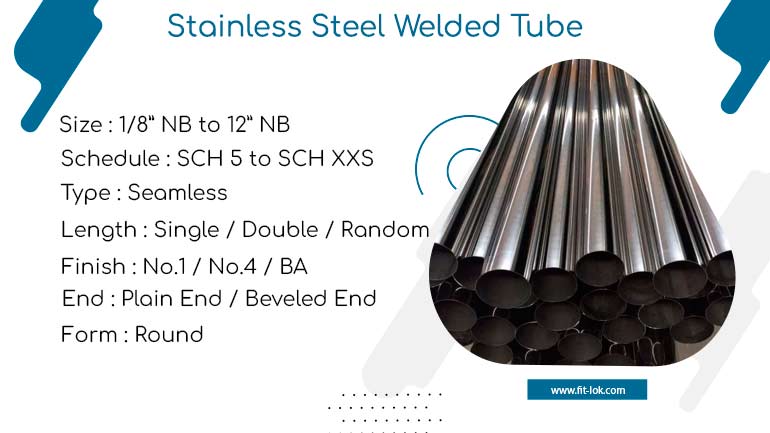

| Specification | ASTM A249/ ASME SA249 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

ASTM A249 Type 304 ERW Tubing

SA 249 Tp 304 Material

Welded 304 Stainless Steel Tubing

ASME SA 249 TP 304 Tube

ASTM A249 Welded SS Tubing

ASTM A249 304 Welded Tubing

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Ti | Fe | |

| 304 | min. | 18.0 | 8.0 | |||||||||

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | 0.10 | ||||

| 304L | min. | 18.0 | 8.0 | |||||||||

| max. | 0.030 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 12.0 | 0.10 | ||||

| 304H | min. | 0.04 | 18.0 | 8.0 | ||||||||

| max. | 0.010 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | |||||

| SS 310 | 0.015 max | 2 max | 0.015 max | 0.020 max | 0.015 max | 24.00 26.00 | 0.10 max | 19.00 21.00 | 54.7 min | |||

| SS 310S | 0.08 max | 2 max | 1.00 max | 0.045 max | 0.030 max | 24.00 26.00 | 0.75 max | 19.00 21.00 | 53.095 min | |||

| SS 310H | 0.04 0.10 | 2 max | 1.00 max | 0.045 max | 0.030 max | 24.00 26.00 | 19.00 21.00 | 53.885 min | ||||

| 316 | min. | 16.0 | 2.03.0 | 10.0 | ||||||||

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316L | min. | 16.0 | 2.03.0 | 10.0 | ||||||||

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| 316TI | 0.08 max | 10.00 14.00 | 2.0 max | 0.045 max | 0.030 max | 16.00 18.00 | 0.75 max | 2.00 3.00 | ||||

| 317 | 0.08 max | 2 max | 1 max | 0.045 max | 0.030 max | 18.00 20.00 | 3.00 4.00 | 57.845 min | ||||

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 20.00 | 3.00 4.00 | 11.00 15.00 | 57.89 min | |||

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 19.00 | 9.00 12.00 | 0.10 max | 5(C+N) 0.70 max | |||

| SS 321H | 0.04 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 19.00 | 9.00 12.00 | 0.10 max | 4(C+N) 0.70 max | |||

| 347/ 347H | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 20.00 | 9.0013.00 | |||||

| 410 | min. | 11.5 | ||||||||||

| max. | 0.15 | 1.0 | 1.00 | 0.040 | 0.030 | 13.5 | 0.75 | |||||

| 446 | min. | 23.0 | 0.10 | |||||||||

| max. | 0.2 | 1.5 | 0.75 | 0.040 | 0.030 | 30.0 | 0.50 | 0.25 | ||||

| 904L | min. | 19.0 | 4.00 | 23.00 | 0.10 | |||||||

| max. | 0.20 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 5.00 | 28.00 | 0.25 | |||

ASME SA 249 TP 304 Tube is available in a thickness range that includes Schedule 5 through Schedule XXS.

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 304/ 304L | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 304H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

| 310 / 310S / 310H | 7.9 g/cm3 | 1402 °C (2555 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

| 306/ 316H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 316L | 8.0 g/cm3 | 1399 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 317 | 7.9 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 321 | 8.0 g/cm3 | 1457 °C (2650 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 347 | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 904L | 7.95 g/cm3 | 1350 °C (2460 °F) | Psi 71000 , MPa 490 | Psi 32000 , MPa 220 | 35 % |

Accept all small/ Large Orders for ASTM A249 Welded SS Tubing, Check ASTM A249 304 Welded Tubing Price Per Kg

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304H | 1.4301 | S30409 | – | – | – | – | – |

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

| SS 310H | – | S31009 | – | – | – | – | – |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

| SS 316H | 1.4401 | S31609 | – | – | – | – | – |

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

| SS 317 | 1.4449 | S31700 | SUS 317 | – | – | – | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | – | – | – | X2CrNiMo18-15-4 |

| SS 321 | 1.4541 | S32100 | SUS 321 | – | – | – | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | – | – | – | X12CrNiTi18-9 |

| SS 347 | 1.4550 | S34700 | SUS 347 | – | 08Ch18N12B | – | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | – | – | – | X6CrNiNb18-12 |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

| NPS | Tolerance, % | |

| + | – | |

| 1/8-2 1 /2 | 20.0 | 12.5 |

| 3~18, t/D≤ 5% | 22.5 | 12.5 |

| 3~18, t/D> 5% | 15.0 | 12.5 |

| ≥ 20, welded | 17.5 | 12.5 |

| ≥ 20, seamless, t/D≤ 5% | 22.5 | 12.5 |

| ≥ 20, seamless, t/D> 5% | 15.0 | 12.5 |

Looking to Buy Sa-249 Welded Tubing from Suppliers, Ask For ready stock of ASTM A249 Type 304 ERW Tubing

| OD inches | Ave. Wall inches | D/t Ratio | ID inches | Tube Cross Sectional Area (in2) | Internal Area (in2) |

|---|---|---|---|---|---|

| 0.250 | 0.020 | 12.50 | 0.210 | 0.0145 | 0.0346 |

| 0.250 | 0.028 | 8.93 | 0.194 | 0.0195 | 0.0296 |

| 0.250 | 0.035 | 7.14 | 0.180 | 0.0236 | 0.0254 |

| 0.250 | 0.049 | 5.10 | 0.152 | 0.0309 | 0.0181 |

| 0.250 | 0.065 | 3.85 | 0.120 | 0.0378 | 0.0113 |

| 0.375 | 0.020 | 18.75 | 0.335 | 0.0223 | 0.0881 |

| 0.375 | 0.028 | 13.39 | 0.319 | 0.0305 | 0.0799 |

| 0.375 | 0.035 | 10.71 | 0.305 | 0.0374 | 0.0731 |

| 0.375 | 0.049 | 7.65 | 0.277 | 0.0502 | 0.0603 |

| 0.375 | 0.065 | 5.77 | 0.245 | 0.0633 | 0.0471 |

| 0.500 | 0.020 | 25.00 | 0.460 | 0.0302 | 0.1662 |

| 0.500 | 0.028 | 17.86 | 0.444 | 0.0415 | 0.1548 |

| 0.500 | 0.035 | 14.29 | 0.430 | 0.0511 | 0.1452 |

| 0.500 | 0.049 | 10.20 | 0.402 | 0.0694 | 0.1269 |

| 0.500 | 0.065 | 7.69 | 0.370 | 0.0888 | 0.1075 |

| 0.500 | 0.083 | 6.02 | 0.334 | 0.1087 | 0.0876 |

| 0.625 | 0.020 | 31.25 | 0.585 | 0.0380 | 0.2688 |

| 0.625 | 0.028 | 22.32 | 0.569 | 0.0525 | 0.2543 |

| 0.625 | 0.035 | 17.86 | 0.555 | 0.0649 | 0.2419 |

| 0.625 | 0.049 | 12.76 | 0.527 | 0.0887 | 0.2181 |

| 0.625 | 0.065 | 9.62 | 0.495 | 0.1144 | 0.1924 |

| 0.625 | 0.083 | 7.53 | 0.459 | 0.1413 | 0.1655 |

| 0.625 | 0.095 | 6.58 | 0.435 | 0.1582 | 0.1486 |

| 0.625 | 0.109 | 5.73 | 0.407 | 0.1767 | 0.1301 |

| 0.750 | 0.028 | 26.79 | 0.694 | 0.0635 | 0.3783 |

| 0.750 | 0.035 | 21.43 | 0.680 | 0.0786 | 0.3632 |

| 0.750 | 0.049 | 15.31 | 0.652 | 0.1079 | 0.3339 |

| 0.750 | 0.065 | 11.54 | 0.620 | 0.1399 | 0.3019 |

| 0.750 | 0.083 | 9.04 | 0.584 | 0.1739 | 0.2679 |

| 0.750 | 0.095 | 7.89 | 0.560 | 0.1955 | 0.2463 |

| 0.750 | 0.109 | 6.88 | 0.532 | 0.2195 | 0.2223 |

| 0.750 | 0.120 | 6.25 | 0.510 | 0.2375 | 0.2043 |

| 0.875 | 0.020 | 43.75 | 0.835 | 0.0537 | 0.5476 |

| 0.875 | 0.028 | 31.25 | 0.819 | 0.0745 | 0.5268 |

| 0.875 | 0.035 | 25.00 | 0.805 | 0.0924 | 0.5090 |

| 0.875 | 0.049 | 17.86 | 0.777 | 0.1272 | 0.4742 |

| 0.875 | 0.065 | 13.46 | 0.745 | 0.1654 | 0.4359 |

| 0.875 | 0.083 | 10.54 | 0.709 | 0.2065 | 0.3948 |

| 0.875 | 0.095 | 9.21 | 0.685 | 0.2328 | 0.3685 |

| 0.875 | 0.109 | 8.03 | 0.657 | 0.2623 | 0.3390 |

| 0.875 | 0.120 | 7.29 | 0.635 | 0.2846 | 0.3167 |

| 1.000 | 0.028 | 35.71 | 0.944 | 0.0855 | 0.6999 |

| 1.000 | 0.035 | 28.57 | 0.930 | 0.1061 | 0.6793 |

| 1.000 | 0.049 | 20.41 | 0.902 | 0.1464 | 0.6390 |

| 1.000 | 0.065 | 15.38 | 0.870 | 0.1909 | 0.5945 |

| 1.000 | 0.083 | 12.05 | 0.834 | 0.2391 | 0.5463 |

| 1.000 | 0.095 | 10.53 | 0.810 | 0.2701 | 0.5153 |

| 1.000 | 0.109 | 9.17 | 0.782 | 0.3051 | 0.4803 |

| 1.000 | 0.120 | 8.33 | 0.760 | 0.3318 | 0.4536 |

| 1.000 | 0.134 | 7.46 | 0.732 | 0.3646 | 0.4208 |

| 1.250 | 0.035 | 35.71 | 1.180 | 0.1336 | 1.0936 |

| 1.250 | 0.049 | 25.51 | 1.152 | 0.1849 | 1.0423 |

| 1.250 | 0.065 | 19.23 | 1.120 | 0.2420 | 0.9852 |

| 1.250 | 0.083 | 15.06 | 1.084 | 0.3043 | 0.9229 |

| 1.250 | 0.095 | 13.16 | 1.060 | 0.3447 | 0.8825 |

| 1.250 | 0.109 | 11.47 | 1.032 | 0.3907 | 0.8365 |

| 1.250 | 0.120 | 10.42 | 1.010 | 0.4260 | 0.8012 |

| 1.250 | 0.134 | 9.33 | 0.982 | 0.4698 | 0.7574 |

| 1.500 | 0.035 | 42.86 | 1.430 | 0.1611 | 1.6061 |

| 1.500 | 0.049 | 30.61 | 1.402 | 0.2234 | 1.5438 |

| 1.500 | 0.065 | 23.08 | 1.370 | 0.2930 | 1.4741 |

| 1.500 | 0.083 | 18.07 | 1.334 | 0.3695 | 1.3977 |

| 1.500 | 0.095 | 15.79 | 1.310 | 0.4193 | 1.3478 |

| 1.500 | 0.109 | 13.76 | 1.282 | 0.4763 | 1.2908 |

| 1.500 | 0.120 | 12.50 | 1.260 | 0.5202 | 1.2469 |

| 1.500 | 0.134 | 11.19 | 1.232 | 0.5750 | 1.1921 |

| 1.500 | 0.148 | 10.14 | 1.204 | 0.6286 | 1.1385 |

| 1.750 | 0.035 | 50.00 | 1.680 | 0.1886 | 2.2167 |

| 1.750 | 0.049 | 40.82 | 1.902 | 0.3003 | 2.8413 |

| 1.750 | 0.065 | 26.92 | 1.620 | 0.3441 | 2.0612 |

| 1.750 | 0.083 | 21.08 | 1.584 | 0.4347 | 1.9706 |

| 1.750 | 0.095 | 18.42 | 1.560 | 0.4939 | 1.9113 |

| 1.750 | 0.109 | 16.06 | 1.532 | 0.5619 | 1.8433 |

| 1.750 | 0.120 | 14.58 | 1.510 | 0.6145 | 1.7908 |

| 1.750 | 0.134 | 13.06 | 1.482 | 0.6803 | 1.7250 |

| 1.750 | 0.148 | 11.82 | 1.454 | 0.7449 | 1.6604 |

| 1.750 | 0.165 | 10.61 | 1.420 | 0.8216 | 1.5837 |

| 2.000 | 0.035 | 57.14 | 1.930 | 0.2161 | 2.9255 |

| 2.000 | 0.049 | 40.82 | 1.902 | 0.3003 | 2.8413 |

| 2.000 | 0.065 | 30.77 | 1.870 | 0.3951 | 2.7465 |

| 2.000 | 0.083 | 24.10 | 1.834 | 0.4999 | 2.6417 |

| 2.000 | 0.095 | 21.05 | 1.810 | 0.5685 | 2.5730 |

| 2.000 | 0.109 | 18.35 | 1.782 | 0.6475 | 2.4941 |

| 2.000 | 0.120 | 16.67 | 1.760 | 0.7087 | 2.4328 |

| 2.000 | 0.134 | 14.93 | 1.732 | 0.7855 | 2.3561 |

| 2.000 | 0.148 | 13.51 | 1.704 | 0.8611 | 2.2805 |

| 2.000 | 0.165 | 12.12 | 1.670 | 0.9512 | 2.1904 |

Application of SS welded tube

- Aerospace industry

- Dairy equipment

- Marine applications

- Automotive manufacturing

- Brewing equipment