SS 316 Dom Tubes Supplier in India

Check seamless mechanical tubing Dimensions & Weight charts

Table of content

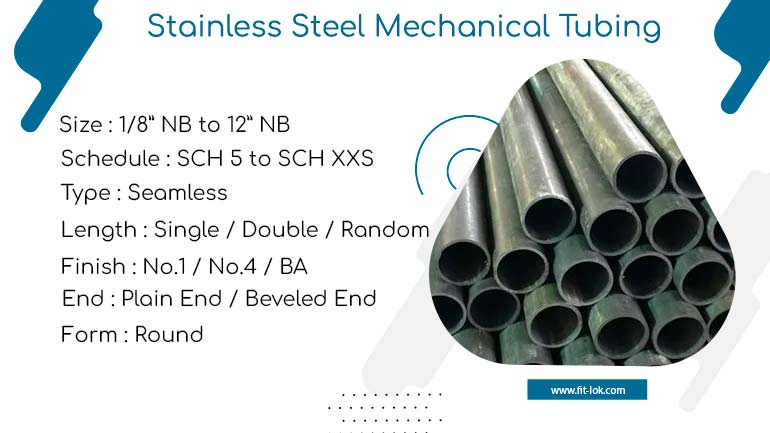

- Stainless Steel Mechanical Tubing Specification

- Heavy Wall Mechanical Tubing Types

- Stainless steel mechanical tube price list

- Thickness of Stainless Steel 304 Dom Tubes

- 316 SS Mechanical Tubing Pressure Rating

- Stainless steel mechanical tube sizes

- SS welded mechanical steel tubing Dimension

- SS 316L Mechanical Tube Tolerance

- Stainless Steel Mechanical Vs DOM Tubing

- SS seamless mechanical tubing Chemical Composition

- Stainless Steel Heavy Wall Mechanical Tubing Mechanical Properties

- Equivalent material of Stainless Steel ERW Mechanical Tube

- Stainless Steel 304 mechanical tubing Application

| Specification | ASTM A249, A312, A554, A269, A270 |

| SS Grades | 304/304L, 304LN, 316/316L, 316H, 316Ti, 316LN, 317/317L, 321, 310S, 347, 304H, 347H, 347HFG, 310H, UNS N8904, UNS 31254. |

| Technique | Cold drawn, Hot rolled, Cold rolled, Extrusion Tube |

| Pressure Boiler Tubing | ASTM A/ASME SA 789, GB 13296, EN 10216-5, JIS G3463, GB 5310, EN10216-2, ASTM A/ASME SA 213, RCCM M3303, DIN 17458 |

| END | Beveled End, Plain End, Treaded |

| Processing Service | Bending, Decoiling, Punching, Cutting, Welding, Moulding |

Stainless Steel 304 Dom Tubes

Seamless mechanical tubing

Heavy Wall Mechanical Tubing

316 Stainless Steel ERW Mechanical Tube

Square mechanical tubing

Welded mechanical steel tubing

We offer both seamless and welded Heavy Wall Mechanical Tubing, providing options for different project requirements.

| Product | Price in USD (Kg) |

Price in Dirham (Kg) |

Price in Euro (Kg) |

|---|---|---|---|

| 9.53X0.5X4650MM SS 304 Mechnical Tube | US $10.16 | 37.31 AED | € 8.75 |

| 9.53X0.5X3300 MM AISI 316 Mechanical Tubing | US $9.25 | 33.97 AED | € 7.96 |

| Typical value (INCHES) | Thickness Range (INCHES) |

|---|---|

| 0.028 | 0.025 through 0.029 |

| 0.065 | 0.060 through 0.065 |

| 0.072 | 0.066 through 0.074 |

| 0.083 | 0.075 through 0.085 |

| 0.095 | 0.087 through 0.097 |

| 0.109 | 0.101 through 0.111 |

| 0.035 | 0.031 through 0.035 |

| 0.042 | 0.038 through 0.042 |

| 0.049 | 0.044 through 0.049 |

| 0.058 | 0.053 through 0.058 |

| 0.12 | 0.112 through 0.122 |

We can provide 316 Stainless Steel ERW Mechanical Tube in basically any size

| Tube Size | Tube Schedule | Temperature (oF) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | 750 | 700 | 650 | 600 | 500 | 400 | 300 | 200 | 100 | |

| 1″ | 40 | 1810 | 1824 | 1867 | 1924 | 2019 | 2171 | 2362 | 2629 | 3048 |

| 80 | 2501 | 2528 | 2580 | 2659 | 2791 | 3002 | 3265 | 3634 | 4213 | |

| 160 | 3646 | 3684 | 3761 | 3876 | 4068 | 4375 | 4759 | 5296 | 6140 | |

| 1 1/2″ | 40 | 1340 | 1354 | 1383 | 1425 | 1496 | 1608 | 1750 | 1947 | 2257 |

| 80 | 1889 | 1909 | 1949 | 2009 | 2108 | 2267 | 2466 | 2744 | 3182 | |

| 160 | 2743 | 2772 | 2829 | 2916 | 3060 | 3291 | 3580 | 3984 | 4619 | |

| 2″ | 40 | 1129 | 1141 | 1165 | 1201 | 1260 | 1355 | 1474 | 1640 | 1902 |

| 80 | 1631 | 1648 | 1682 | 1734 | 1820 | 1957 | 2129 | 2369 | 2747 | |

| 160 | 2671 | 2699 | 2755 | 2840 | 2980 | 3205 | 3486 | 3880 | 4499 | |

| 3″ | 40 | 1072 | 1084 | 1106 | 1140 | 1196 | 1287 | 1400 | 1558 | 1806 |

| 80 | 1516 | 1532 | 1564 | 1612 | 1691 | 1819 | 1979 | 2202 | 2553 | |

| 160 | 2280 | 2304 | 2352 | 2424 | 2544 | 2736 | 2976 | 3312 | 3840 | |

| 4″ | 40 | 909 | 919 | 938 | 967 | 1014 | 1091 | 1187 | 1321 | 1531 |

| 80 | 1314 | 1328 | 1355 | 1397 | 1466 | 1577 | 1715 | 1909 | 2213 | |

| 160 | 2138 | 2161 | 2206 | 2273 | 2386 | 2566 | 2791 | 3106 | 3601 | |

| OD (inch) | Wall Thickness (inch) |

|---|---|

| 1.375 | 0.25 |

| 1.375 | 0.188 |

| 1.75 | 0.375 |

| 1.75 | 0.25 |

| 1.75 | 0.188 |

| 2.125 | 0.375 |

| 2.125 | 0.25 |

| 2.125 | 0.188 |

| 1.25 | 0.375 |

| 1.25 | 0.25 |

| OD (in.) | WT (in.) | lb/ft | Max. OD (mm) | Min. ID (mm) | Max. OD (mm) | Min. ID (mm) |

|---|---|---|---|---|---|---|

| Size | Chucked true to ID | Chucked true to OD | ||||

| 1.5 | 0.313 | 4.029 | 1.415 | 1 | 1.457 | 1.037 |

| 1.5 | 0.375 | 4.58 | 1.412 | 0.181 | 1.457 | 0.931 |

| 1.625 | 0.25 | 3.732 | 1.544 | 1.231 | 1.582 | 1.265 |

| 1.625 | 0.313 | 4.453 | 1.54 | 1.122 | 1.582 | 1.159 |

| 1.625 | 0.375 | 5.089 | 1.537 | 1.012 | 1.582 | 1.052 |

| 1.75 | 0.25 | 4.071 | 1.669 | 1.356 | 1.707 | 1.391 |

| 1.75 | 0.313 | 4.877 | 1.665 | 1.247 | 1.707 | 1.284 |

| 1.75 | 0.375 | 5.598 | 1.662 | 1.138 | 1.707 | 1.178 |

| 1.875 | 0.25 | 4.41 | 1.794 | 1.482 | 1.832 | 1.517 |

| 1.875 | 0.313 | 5.301 | 1.79 | 1.372 | 1.832 | 1.41 |

| 1.875 | 0.375 | 6.107 | 1.787 | 1.263 | 1.832 | 1.303 |

| 1.875 | 0.438 | 6.827 | 1.783 | 1.154 | 1.832 | 1.196 |

| 2 | 0.375 | 6.615 | 1.912 | 1.389 | 1.957 | 1.428 |

Accept all small/ Large Orders for square mechanical tubing, Check welded mechanical steel tubing Price Per Kg

| Size Inches | ODB Under/Over, In. | Cut Length Inches | Wall CD Under/Over % | OvalityB Double Tolerlance Of OD When Wall Is: |

|---|---|---|---|---|

| Under 1/2 | 0.005 | +1/8 to 0 | 15 | < 0.015 |

| 1/2 to 1-1/2 excl. | 0.005 | +1/8 to 0 | 10 | < 0.065 |

| Feature | Mechanical Tubing | DOM Tubing |

|---|---|---|

| Material | Stainless Steel Grades | Carbon steel Grades |

| Surface Finish | Can be polished | Smooth Surfaces |

| Strength | Moderate to high | High Tensile Strength |

| Wall Thickness | Nominal | Uniform and precise |

| Straightness | Moderate | Very straight |

| Grade | Carbon | Phosphorus | Sulfur | Manganese | Silicon | Nickel | Chromium | Molybdenum |

|---|---|---|---|---|---|---|---|---|

| TP304 | 0.08 | 0.045 | 0.03 | 2 | 1 | 8.0-11.0 | 18.0-20.0 | |

| TP316 | 0.08 | 0.045 | 0.03 | 2 | 1 | 11.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| TP304L | 0.035 | 0.045 | 0.03 | 2 | 1 | 8.0-13.0 | 18.0-20.0 | |

| TP316L | 0.035 | 0.045 | 0.03 | 2 | 1 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|

| 304 | 540 – 750 Mpa | 230 Mpa | 45% |

| 304L | 520 – 700 Mpa | 220 Mpa | 45% |

| 316 | 515 Mpa | 205 Mpa | 40% |

| 316L | 485 Mpa | 170 Mpa | 40% |

| STANDARD | JIS | UNS | GOST | WNR | BS | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 304 | SUS 304 | S30400 | 08Х18Н10 | 1.4301 | 304S31 | Z7CN18‐09 | X5CrNi18-10 |

| SS 304L | SUS 304L | S30403 | 03Х18Н11 | 1.4306 / 1.4307 | 3304S11 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 316 | SUS 316 | S31600 | – | 1.4401 / 1.4436 | 316S31 / 316S33 | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | SUS 316L | S31603 | 03Ch17N14M3 / 03Ch17N14M2 | 1.4404 / 1.4435 | 316S11 / 316S13 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |