Top notch ASTM A213 TP347 Tube supplier in India

Count on our expertise and industry knowledge as the leading stockist and distributor of high-temperature Stainless Steel Type 347 ERW Tubing and SS Grade 347 Round Tubing.

Table of content

- 347 stainless steel tube Specification

- Size Chart of Alloy 347 Round Tubing

- Various types of 347 SS tube

- Stainless Steel 347 Tube Price List

- ASTM A213 TP 347 Seamless Tube Chemical composition

- UNS S34700 Welded Tubing Mechanical properties

- AISI 347 welded tube Physical properties

- SA213 TP347 Polished Tube Equivalent grade

- Thermal Properties of 347 SS Capillary Tube

- Thickness Chart of SS 347 Welded Tube

- Ready stock of stainless steel 347 tube

- Testing requirements of AISI 347 Instrumentation tube

- Welding of A213 TP347 Mechanical Tubing

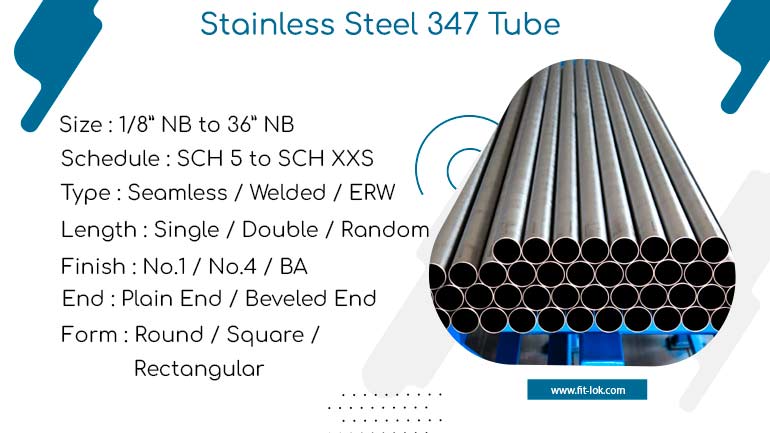

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

SA213 TP347 Polished Tube and SA213 Tp347 Cres Tubing has moderate strength with excellent cold formability, weld ability.

AISI 347 welded tube

347 Stainless Steel Tubing

Stainless Steel Type 347 ERW Tubing

SS Grade 347 Round Tubing

SA213 TP347 Polished Tube

ASTM A213 TP347 Exhaust Tubing

| Product | Price in USD (Kg) |

Price in Dirham (Kg) |

Price in Euro (Kg) |

|---|---|---|---|

| 8NB OD SS 347 Seamless Tube, Sch 40 | US $3.26 | 11.97 AED | € 2.80 |

| OD 219.1MM X 12.7MM AISI 347 Welded Tubing | US $2.94 | 10.80 AED | € 2.53 |

When considering UNS S34700 Condenser Tubes and 347 Stainless Steel Rectangular Tubing one must take into account the thickness range from Schedule 5 to Schedule XXS.

| Grade | C | Si | Mn | S | P | Ni | Cb | Cr | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 347 | 0.08 max | 1.0 max | 2.0 max | 0.030 max | 0.045 max | 9.00 – 13.00 | 10xC – 1.10 | 17.00 – 20.00 | 62.74 min |

| Tensile strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|

| 520-1100 Mpa | 205 Mpa | 60 % | 160-190 |

| Density | Melting point | Modulus of elasticity | Electrical resistivity |

|---|---|---|---|

| 7.93 g.cm-3 | 1400-1425 °C | 190-210 GPa | 70-73 µOhm.cm |

Choose cold drawn ASTM A213 TP347 Exhaust Tubing and DIN 1.4550 Tubing for superior surface finish and tight tolerances.

| STANDARD | WNR | JIS | UNS | EN | GOST |

|---|---|---|---|---|---|

| SS 347 | 1.455 | SUS 347 | S34700 | X6CrNiNb18-10 | 08Ch18N12B |

| Coefficient of thermal expansion | 16-18 x10-6 K-1 |

|---|

| Tube OD (inches) | Wall Thickness (inches) | Schedule |

|---|---|---|

| 1/8 | 0.035 | SCH 10 |

| 1/4 | 0.049 | SCH 40 |

| 3/8 | 0.049 | SCH 40 |

| 1/2 | 0.049 | SCH 40 |

| 1/2 | 0.083 | SCH 80 |

| 3/4 | 0.049 | SCH 40 |

| 3/4 | 0.083 | SCH 80 |

| 1 | 0.065 | SCH 40 |

| 1 1/4 | 0.14 | SCH 40 |

| 1 1/2 | 0.14 | SCH 40 |

| 1 1/2 | 0.14 | SCH 80 |

| 2 | 0.14 | SCH 40 |

| 3 | 0.14 | SCH 80 |

| ASME SA213 TP347 Square Tubing | Stainless Steel Type 347 EFW Tube |

| SA213 347 SS Decorative Tube | ASME SA213 TP347 Polished Tube |

| DIN 1.4550 Stainless Steel 347 Polish Tube | ASTM A 213 347 Stainless Steel Elliptical and Oval Tubes |

| ASTM A 213 347 Stainless Steel Seamless Tubing | SS 347 Coil Tubing |

| SA 213 TP 347 Stainless Steel High Pressure Tube | ASTM A213 TP 347 Heat exchanger Tubes |

| 347 Stainless Steel Exhaust Tubing | Stainless Steel DIN 1.4550 ERW Tube |

| SA213 TP347 Rectangular Tubing | SS UNS S34700 ERW Tubing |

| JIS SUS347 UNS S34700 Cold Drawn Tube | SA 213 Grade 347 Condenser Tubes |

- TIG-Welding

- Laser Beam Welding

- MAG-Welding Solid Wire

- Arc Welding (E)

- Submerged Arc Welding (SAW)