Are you finding ASTM A213 TP316 Tube supplier in India

As stockist we provide UNS S31600 Welded Tubes and ASME SA213 TP316 cold redrawn Tubing in size range from 0.125 to 4 inch at a reasonable cost

What factors to be consider while buying Stainless steel 316 tube for food-grade system?

- Material Grade & Certification

- Surface Finish

- Cleaning and Sanitation Compliance (FDA 21 CFR 177.2600 or EHEDG)

- Fabrication & Weld Quality

- Dimensions & Tolerances

- Packaging & Handling

- Compatibility with Fittings and Standards

- ASTM A270-S2 compliant

Table of content

- Specification of Stainless Steel 316 Tube

- Available types of ASME SA 213 TP 316 Tube

- 316 Stainless Steel Tube price list

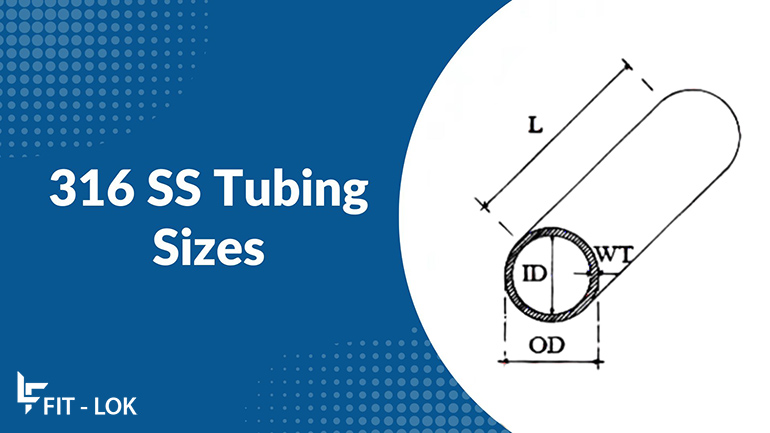

- Sizes of 316 SS tubing

- Diameter Tolerance of SS 316 Cold Drawn Tube

- Maximum internal pressure of SA213 TP316L Tube

- Heat Resistance and Heat Treatment of SA 213 Grade TP316 Tube

- Ready stock of 316 stainless steel tube

- Testing certificates of ASTM A213 Grade 316 Boiler Tube

- SA 213 TP 316 Round Tubing applications

- Alternative Grades for 316 SS Seamless tubes

- ASTM A213 Grade 316 Round Tube chemical composition

- UNS S31600 High Pressure Tube Mechanical properties

- SA213 TP316 tubing Physical properties

- AISI 316 Round Tube Equivalent grade

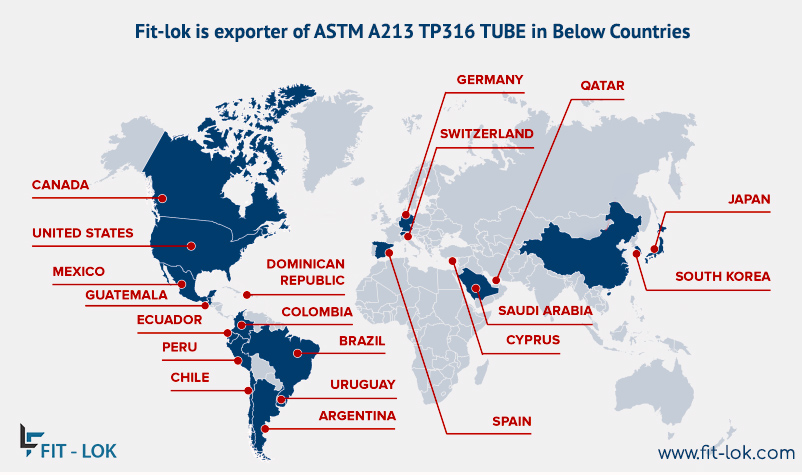

- Export record of ASTM A213 TP316 Tubes

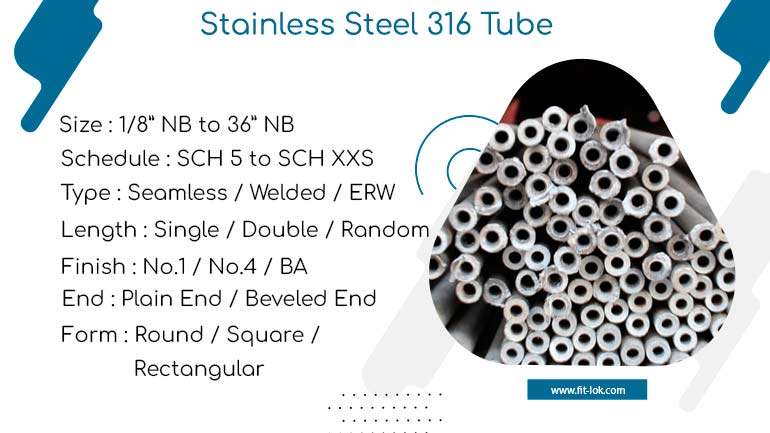

| Specification | ASTM A213/ ASME SA213 |

| Surfaces |

|

| Standard length | 6 Mtr |

| Thickness Range | SCH 5 to SCH XXS |

| Delivery Condition | MF, Polished, Annealed and Pickled, Bright Annealed, Cold Drawn |

| Manufacturing Type | Seamless / ERW / Welded |

| Value Added Services |

|

| Surface Finish | No.1, BA, 2B, No.3, No.8, 500G, 8K, HL, No.4, 2D, 800G Mirror finish, 1D, 180G, 400G Satin/ Hairline, Mirror Polished, 400G, 320G, 600G |

| END | Beveled End, Plain End, Treaded Tubes |

| Technique | Cold rolled, Cold drawn, Hot rolled, Extrusion Tubes |

| Processing Service | Bending, Welding, Punching, Cutting, Decoiling, Moulding |

| Tolerance |

|

316 Stainless Steel welded Tube

WNR 1.4401 ERW Tube

UNS S31600 Welded Tubes

ASME SA213 TP316 cold redrawn Tubing

SA 213 Gr 316 High Precision Tube

SS 316 Electropolished Tube

| Product | Price in USD | Price in Dirham | Price in Euro |

|---|---|---|---|

| O.D.19.05MM X W.T.1.65MM X L:16187MM SA 213 TP316 Tube Cold finished | US $5.39 per kg | 19.80 AED per kg | € 4.73 per kg |

| Hot Finish SA 213 TP 316L Tubing (OD: 42 MM) | US $2.92 per Kg | 10.73 AED per Kg | € 2.56 per Kg |

| ASTM A213 TP316L Seamless Tube (Hot Finished) SIZE-42.2*2.77 LENGTH-10 | US $2.98 per Kg | 10.95 AED per Kg | € 2.62 per Kg |

When it comes to 316 Stainless Steel welded Tube and WNR 1.4401 ERW Tube the thickness can be as low as Schedule 5 or as high as Schedule XXS.

| Inside Diameter (MM) | Outside Diameter (MM) | Wall thickness (MM) |

|---|---|---|

| 1 | 2 | 0.5 |

| 1.5 | 2 | 0.25 |

| 1.5 | 2.5 | 0.5 |

| 2 | 6 | 2 |

| 2 | 4 | 1 |

| 2 | 5 | 1.5 |

| 2.4 | 3 | 0.3 |

| 3 | 6 | 1.5 |

| 3 | 5 | 1 |

| 3.5 | 4.5 | 0.5 |

| 3.5 | 5 | 0.75 |

| 4 | 6 | 1 |

| 4 | 8 | 2 |

| 4 | 5 | 0.5 |

| 4.5 | 5 | 0.25 |

| 4.5 | 6 | 0.75 |

| 5 | 6 | 0.5 |

| 5 | 7 | 1 |

| 5 | 8 | 1.5 |

| 6 | 9 | 1.5 |

| 6 | 10 | 2 |

| 6 | 8 | 1 |

| 7 | 8 | 0.5 |

| 7 | 10 | 1.5 |

| 8 | 10 | 1 |

| 9 | 10 | 0.5 |

| 10 | 12 | 1 |

| NPS | OD Tolerance | |||

|---|---|---|---|---|

| + | – | |||

| inch | mm | inch | mm | |

| 1/8~1 1 /2 > 1 1 /2~4 > 4~8 > 8~18 > 18~26 > 26~34 > 34~48 |

1/64(0.015) 1/32(0.031) 1/16(0.062) 3/32(0.093) 1/8(0.125) 5/32(0.156) 3/16(0.187) |

0.4 0.8 1.6 2.4 3.2 4.0 4.8 |

1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) 1/32(0.031) |

0.8 0.8 0.8 0.8 0.8 0.8 0.8 |

| Outside Diameter | Wall Thickness | Pressure Bar | ||||||

|---|---|---|---|---|---|---|---|---|

| MM | MM | 100°F | 200°F | 300°F | 400°F | 500°F | 600°F | 700°F |

| 12.7 | 0.889 | 152 | 152 | 152 | 143 | 135 | 128 | 123 |

| 12.7 | 1.245 | 217 | 217 | 217 | 204 | 192 | 182 | 175 |

| 12.7 | 1.651 | 297 | 297 | 297 | 279 | 263 | 249 | 240 |

| 15.88 | 1.245 | 171 | 171 | 171 | 161 | 151 | 143 | 138 |

| 15.88 | 1.651 | 232 | 232 | 232 | 218 | 206 | 195 | 188 |

| 19.05 | 1.651 | 191 | 191 | 191 | 179 | 169 | 160 | 154 |

| 19.05 | 2.11 | 249 | 249 | 249 | 234 | 221 | 209 | 201 |

| 25.4 | 1.651 | 141 | 141 | 141 | 132 | 125 | 118 | 114 |

| 25.4 | 2.11 | 183 | 183 | 183 | 172 | 162 | 153 | 148 |

Specialized heat treatments can enhance the mechanical properties of SA 213 Gr 316 High Precision Tube and SS 316 Electropolished Tube

| Heat Resistance | In intermittent service upto 870 °C |

|---|---|

| Heat Treatment | 1010-1120 °C and cool rapidly |

| ASTM A249 TP 316 Electropolished Tubing | SS A249 TP316 Rectangular Tubes |

| Stainless Steel 1.4436 Square Tubing | 316 Stainless Steel Polished Tubes |

| 316 SS Tubing | Stainless Steel 316 Fabricated Tubes |

| SS A249 TP316 12mm Tubes | 316 SS Seamless Tubing |

| ASME SA249 TP 316 High Pressure Tubes | UNS S31600 Thin Wall Tubing |

| 316 Stainless Steel Electropolished Tubes | 316 SS Cold Drawn Seamless Tubes |

| Stainless Steel 316 Hydraulic Tubing | UNS S31600 Coiled Tubes |

| ASTM A249 TP 316 ERW Tube | ASME SA249 TP 316 Electropolished Tubes |

- Mill Test Certificate (EN 10204 Type 3.1 or 3.2)

- Hydrostatic Test Certificate

- Eddy Current Testing

- Ultrasonic Testing

- IGC Test Certificate

- Hardness Test

- Flattening Test

- PMI Testing

- Impact Testing

- Visual Inspection

- Flaring Testing

- Tensile Test

- Instrumentation Industry

- Oil & Gas Industry

- Pharmaceutical Industry

- Pulp & Paper Industry

- Chemical Processing

- Petrochemical

- Marine Applications

- Construction & Architecture

- Aerospace

- Cryogenic Applications

- Food Processing

| Grades | Feature |

|---|---|

| 316Ti | It has better resistance to temperature around 600-900 °C |

| 904L | Exhibit higher resistance even at elevated temperature even in chlorides condition |

| 317L | Higher resistance to chlorides compared to 316L |

| Duplex 2205 | It has higher strength than 316 material, also it has higher resistance in different media |

We are here to help you with any SA213 316 SS Rectangular Tube and SA 213 Gr 316 Hydraulic Tubing requirements to fulfil your project’s requirements

| Grade | Si | S | C | P | Cr | Ni | Mn | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| A213 TP316 | 1.0 max | 0.030 max | 0.08 max | 0.045 max | 16.00 – 18.00 | 11.00 – 14.00 | 2.0 max | 2.00 – 3.00 | 67.845 min |

| Melting Point | Density | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

|---|---|---|---|---|

| 1400 °C (2550 °F) | 8.0 g/cm3 | Psi – 30000 , MPa – 205 | Psi – 75000 , MPa – 515 | 0.35 |

| Property | Value |

|---|---|

| Electrical Resistivity | 0.74 x 10-6Ω.m |

| Modulus of Elasticity | 193 GPa |

| Thermal Expansion | 15.9 x 10-6/K |

| Thermal Conductivity | 16.3 W/m.K |

| STANDARD | UNS | WERKSTOFF NR. | JIS | BS | EN | AFNOR |

|---|---|---|---|---|---|---|

| SS 316 | S31600 | 1.4401 / 1.4436 | SUS 316 | 316S31 / 316S33 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | Z7CND17-11-02 |

| Product | Country |

|---|---|

| 14.6mm * 1mm * 3100 mm A213 TP316 bright annealed seamless tubes | Rotterdam, Netherlands |

| 1 inch * 0.065″ * 6096mm ASME SA213 TP316 Seamless Tube (bright annealed) | Algeciras, Spain |

| 19.05 * 1.651 * 3000 mm SS 316 Welded Tube (cold finished) | Manzanillo, Mexico |

| 12.7mm * 1.245mm * 6096mm ASTM A213 TP316 Tubing (Seamless) | Lagos, Nigeria |