One of the biggest ASTM A213 TP304l Tube supplier in India

The dimensional accuracy and surface finish of UNS S30400 Welded Tubes and Cold redrawn SS 304l Tubes are important factors to consider when evaluating their price and quality.

How to cut Stainless steel 304l tube?

There are multiple methods by which we can cut SS 304L Tubing

- Tube Cutter : Its best for Thin-walled, small-diameter tubing

- Cold Saw : This method is used for larger OD or thicker wall tubes

- Band Saw : Its used for general cutting

- Orbital Tube Cutter : This method is mainly used in sanitary or pharma applications

Table of content

- Specification of Stainless Steel 304L Tube

- SS 304L Tube Price list

- Different types of ASME SA 213 TP 304L Tube

- Size chart of 304L SS Erw tubing

- Stock list of SS 304l tube

- SS 304L Cold Drawn Tube dimensions

- Testing of ASTM A213 TP 304L Polished Tube

- Advantages of AISI 304L Seamless Tubing

- ASME SA213 TP304L Stainless Steel Tubing Properties and Charecteristics

- SA 213 Gr 304L Tubes Applications

- What does “L” stands for in SS 304L Tubing

- WNR 1.4306 ERW Tube Heat treatment

- 304L Stainless Steel Tubes Max internal pressure

- Corrosion resistance of UNS S30403 High Pressure Tubes in Nitric Acid

- Stress Corrosion Cracking test of ASME SA 213 TP304L Straight Tubing

- Cleaning of SUS 304L Sanitary Tubing

- Why buy Stainless Steel 304L Tube from Fit-Lok?

- ASTM A213 Grade 304L Round Tube chemical composition

- SS 304L Welded Tube Mechanical properties

- SA213 TP304L tubing Physical properties

- AISI 304L Tube Equivalent grade

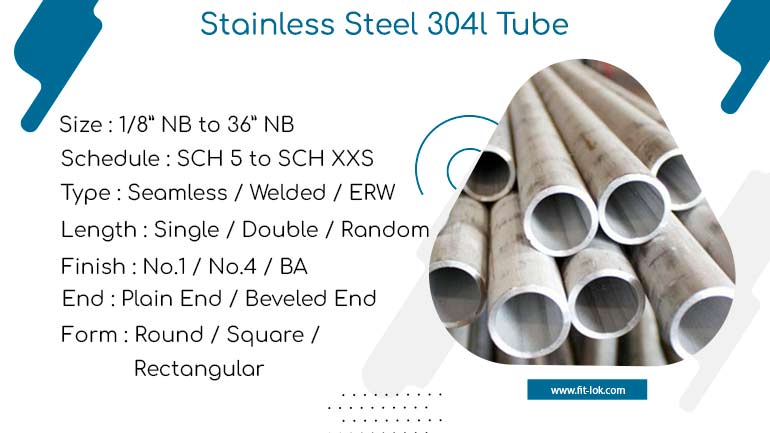

| Specification | ASTM A213/ ASME SA213 |

| Standard length | 6 metres |

| Surfaces |

|

| Manufacturing Type | Seamless / ERW / Welded |

| Delivery Condition | MF, Polished, Bright Annealed, Annealed and Pickled |

| Thickness Range | Sch 5 to Sch XXS |

| Surface Finish | 800G Mirror finish, BA, 500G, 2B, No.1, No.3, No.8, 8K, HL, No.4, 2D, 1D, 180G, 400G Satin/ Hairline, Mirror Polished, 400G, 320G, 600G |

| Value Added Services |

|

| Processing Service | Punching, Welding, Bending, Decoiling, Cutting, Moulding |

| END | Beveled End, Plain End, Treaded |

| Technique | Cold rolled, Cold drawn, Hot rolled, Extrusion Tubes |

| Tolerance |

| Product | Price in USD | Price in Dirham | Price in Euro |

|---|---|---|---|

| 304L Stainless Steel seamless tube OD 6,35 mm x 0,89 mm | US $19.21 per piece | 70.56 AED per piece | € 16.89 per piece |

| DIN 1.4306 Semaless Tube DN10 OD 15 mm x 1 mm, 100cm | US $27.79 per piece | 102.10 AED per piece | € 24.44 per piece |

| DN10 OD 15 mm x 3 mm AISI 304L Tube 100cm | US $46.25 per piece | 169.91 AED per piece | € 40.67 per piece |

| DN10 OD 19,05 mm x 2,77 mm 304L Stainless steel acid-resistant seamless tube | US $46.34 per piece | 170.24 AED per piece | € 40.75 per piece |

304l Stainless Steel Tubing

WNR 1.4306 ERW Tube

UNS S30400 Welded Tubes

Cold redrawn SS 304l Tubes

SA213 304L SS Thin Wall Tubing

ASTM A213 Grade 304L Seamless Tube

| Wall Thickness, mm | Outside Diameter, mm | Weight, kg/m |

|---|---|---|

| 1 | 6 | 0,123 |

| 1 | 8 | 0,173 |

| 1 | 10 | 0,222 |

| 1 | 12 | 0,272 |

| 1 | 13 | 0,296 |

| 1 | 14 | 0,321 |

| 1 | 15 | 0,346 |

| 1 | 16 | 0,370 |

| 1 | 17,2 | 0,400 |

| 1 | 18 | 0,420 |

| 1 | 19,05 | 0,446 |

| 0,8 | 20 | 0,379 |

| 1 | 21,3 | 0,501 |

| 0,8 | 22 | 0,419 |

| 1,5 | 23 | 0,796 |

| 0,8 | 25 | 0,478 |

| 1 | 25,4 | 0,603 |

| 1,2 | 26,9 | 0,762 |

| 1 | 28 | 0,667 |

| 1,5 | 29 | 1,019 |

| 1 | 30 | 0,716 |

| 1 | 32 | 0,765 |

| 1,5 | 33 | 1,167 |

| 3,2 | 33,7 | 2,410 |

| 1 | 34 | 0,815 |

| 1 | 35 | 0,840 |

| 1 | 38,1 | 0,916 |

| 1 | 40 | 0,963 |

| 1,5 | 41 | 1,463 |

| 1,5 | 42 | 1,500 |

| 1,2 | 42,4 | 1,221 |

| 1,5 | 43 | 1,537 |

| 1,2 | 44,5 | 1,283 |

| 1,2 | 45 | 1,298 |

| 1,2 | 48,3 | 1,396 |

| 1 | 50 | 1,210 |

| 1 | 50,8 | 1,230 |

| 1 | 51 | 1,235 |

| 1 | 52 | 1,259 |

| 1,5 | 53 | 1,908 |

| 1,2 | 54 | 1,565 |

| 1,2 | 57 | 1,653 |

| 1,2 | 60,3 | 1,751 |

| 1,2 | 63,5 | 1,846 |

| 1,2 | 70 | 2,039 |

| ASTM A249 TP 304L Electropolished Tubing | 304L Stainless Steel Rectangular Tube |

| UNS S30403 Square Tubing | Stainless Steel 1.4306 Polished Tube |

| ASME SA249 TP 304L Tubing | Stainless Steel 304L Fabricated Tube |

| 304L Stainless Steel 12mm Tube | ASME SA249 TP 304L Seamless Tubing |

| SS A249 TP304L High Pressure Tube | 304L SS Thin Wall Tubing |

| Stainless Steel 1.4306 Electropolished Tubes | ASME SA249 TP 304L Cold Drawn Seamless Tube |

| Stainless Steel 304L Hydraulic Tubing | 304L SS Coiled Tube |

| ASTM A249 TP 304L ERW Tube | SS A249 TP304L Electropolished Tube |

| 304L Stainless Steel Rectangular Tubing | Stainless Steel 1.4306 CDW Tube |

| ASME SA249 TP 304L Electropolish Tube | UNS S30403 Capillary Tubing |

| B.W.G | Wall Thickness | Outside Diameter | ||||||||

| 2 | 1.75 | 1.5 | 1.25 | 1 | 0.875 | 0.75 | 0.625 | 0.5 | ||

| 10 | 3.404 | 43.992 | 31.292 | 24.942 | 21.767 | 18.592 | 15.417 | 12.242 | 9.067 | 5.892 |

| 11 | 3.048 | 44.704 | 32.004 | 25.654 | 22.479 | 19.304 | 16.129 | 12.954 | 9.779 | 6.604 |

| 12 | 2.769 | 45.262 | 32.562 | 26.212 | 23.037 | 19.862 | 16.687 | 13.512 | 10.337 | 7.162 |

| 13 | 2.413 | 45.974 | 33.274 | 26.924 | 23.749 | 20.574 | 17.399 | 14.224 | 11.049 | 7.874 |

| 14 | 2.108 | 46.584 | 33.884 | 27.534 | 24.359 | 21.184 | 18.009 | 14.834 | 11.659 | 8.484 |

| 15 | 1.829 | 47.142 | 34.442 | 28.092 | 24.917 | 21.742 | 18.567 | 15.392 | 12.217 | 9.042 |

| 16 | 1.651 | 47.498 | 34.798 | 28.448 | 25.273 | 22.098 | 18.923 | 15.748 | 12.573 | 9.398 |

| 17 | 1.473 | 47.854 | 35.154 | 28.804 | 25.629 | 22.454 | 19.279 | 16.104 | 12.929 | 9.754 |

| 18 | 1.245 | 48.31 | 35.61 | 29.26 | 26.085 | 22.91 | 19.735 | 16.56 | 13.385 | 10.21 |

| 19 | 1.067 | 48.666 | 35.966 | 29.616 | 26.441 | 23.266 | 20.091 | 16.916 | 13.741 | 10.566 |

| 20 | 0.889 | 49.022 | 36.322 | 29.972 | 26.797 | 23.622 | 20.447 | 17.272 | 14.097 | 10.922 |

| 21 | 0.813 | 49.174 | 36.474 | 30.124 | 26.949 | 23.774 | 20.599 | 17.424 | 14.249 | 11.074 |

| 22 | 0.711 | 49.378 | 36.678 | 30.328 | 27.153 | 23.978 | 20.803 | 17.628 | 14.453 | 11.278 |

| 23 | 0.635 | 49.53 | 36.83 | 30.48 | 27.305 | 24.13 | 20.955 | 17.78 | 14.605 | 11.43 |

| 24 | 0.559 | 49.682 | 36.982 | 30.632 | 27.457 | 24.282 | 21.107 | 17.932 | 14.757 | 11.582 |

| Test | Standard Method |

|---|---|

| Chemical Composition Test | ASTM E1086 |

| Tensile Test | ASTM E8 / E8M |

| Hardness Test | ASTM E18 |

| Flattening Test | ASTM A213 |

| Flaring Test | ASTM A213 |

| Hydrostatic Test | ASTM E213 |

| Grain Size Test | ASTM E112 |

| Intergranular Corrosion Test | ASTM A262 |

- Can be used in corrosive condition

- Clean internal and external surface

- Excellent straightness

- Lower cost compared to higher grades

- High Temperature Strength

- Easy Fabrication

| Properties | Character |

|---|---|

| Corrosion Resistance | Excellent resistance to oxidation and pitting in chloride environments |

| Low Carbon Content | Max 0.03% carbon |

| High Temperature Performance | up to 816°C (1,500°F) |

| Non Magnetic | Austenitic structure |

| Formability & Weldability | Good ductility and compatibility |

L in 304L stands for lower carbon content upto 0.035% carbon, It often have slightly lower strength and they are resistant to sensitization in heat treatments.

| Heat treatment | 1900 [1040]F water or other rapid cool |

| Outside Diameter | Wall Thickness | Pressure Bar | ||||||

| mm | mm | 100°F | 200°F | 300°F | 400°F | 500°F | 600°F | 700°F |

| 15.88 | 1.245 | 171 | 171 | 171 | 161 | 151 | 143 | 138 |

| 15.88 | 1.651 | 232 | 232 | 232 | 218 | 206 | 195 | 188 |

| 19.05 | 1.651 | 191 | 191 | 191 | 179 | 169 | 160 | 154 |

| 19.05 | 2.11 | 249 | 249 | 249 | 234 | 221 | 209 | 201 |

| 25.4 | 1.651 | 141 | 141 | 141 | 132 | 125 | 118 | 114 |

| 25.4 | 2.11 | 183 | 183 | 183 | 172 | 162 | 153 | 148 |

| % Nitric Acid | Temperature ° F (°C) |

Corrosion Rate Mils/Yr (mm/a) |

| 10 | 300 (149) | 5.0 (0.13) |

| 20 | 300 (149) | 10.1 (0.25) |

| 30 | 300 (149) | 17.0 (0.43) |

| Halide (Chloride Stress Corrosion Tests) | ||

| Test | U-Bend (Highly Stressed) Samples | |

| 304L | ||

| 33% Lithium Chloride, Boiling |

Base Metal Welded |

Cracked, 14 to 96 hours

Cracked, 18 to 90 hours |

| 26% Sodium Chloride, Boiling |

Base Metal Welded |

Cracked, 142 to 1004 hours

Cracked, 300 to 500 hours |

Cleaning is important to remove any residual like oil, grease or debris. In pharma and food industry to prevent bacterial growth cleaning of SS 304L sanitary tube is required.

Check the Type of cleaning agents we can use to clean these tubes.

| Type | Products |

|---|---|

| Alkaline | Enzol, NaOH |

| Acidic | Nitric, citric acid |

| Solvent | IPA, acetone |

| Biocidal | Peracetic acid |

- Competitive Pricing

- Established Manufacturing Base

- Quality Compliance & Certifications

- Customization

- Efficient Export Logistics

- Reliable Supply Chain

- Comprehensive Product Range

- Durable Material

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 304l | min. | – | – | – | – | – | 18.0 | – | 8.00 | – |

| max. | 0.030 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 12.00 | 0.10 | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 304l | 485 | 170 | 40 | 92 | 201 |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 304L | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | GOST | ||

|---|---|---|---|---|---|---|---|---|

| BS | En | No | Name | |||||

| 304l | S30403 | 304S31 | 58E | 1.4306 / 1.4307 | X5CrNi18-10 | 2332 | SUS 304L | 03Х18Н11 |