We are leading stainless steel seamless tube supplier in Mumbai

Find the right dimensions for your applications in our SS tube range.

Table of content

| Specification | ASTM A213/ ASME SA213 |

| Surfaces | |

| Standard length | 6 metres |

| Delivery Condition | MF, Bright Annealed, Polished, Annealed and Pickled, Cold Drawn |

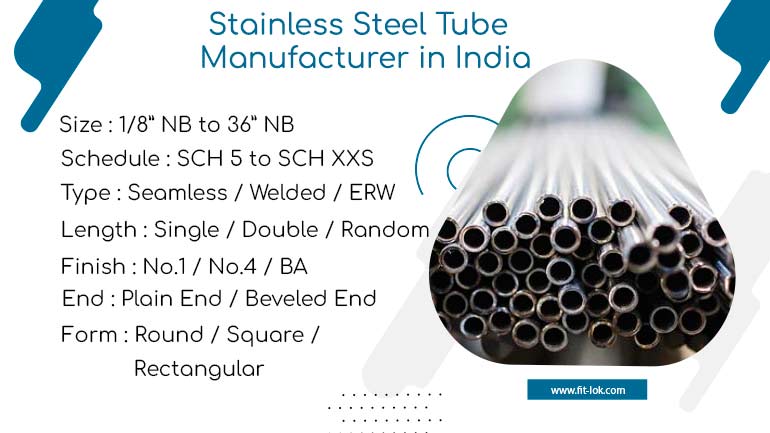

| Thickness Range | Schedule 5 to Schedule XXS |

| Manufacturing Type | CEW / Seamless / DOM / ERW / Fabricated / Welded / CDW / CDS / 100% X Ray Welded |

| Surface Finish | BA, 500G, 2B, No.1, No.3, No.8, 800G Mirror finish, 8K, HL, No.4, 2D, Mirror Polished, 1D, 180G, 400G Satin/ Hairline, 320G, 400G, 600G |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded Tubes |

| Processing Service | Welding, Decoiling, Bending, Punching, Cutting, Moulding |

| Technique | Cold drawn, Cold rolled, Hot rolled, Extrusion Tubes |

| Tolerance |

SS Electropolish Tube

ss seamless tube

Stainless Steel Seamless Tubing

SS Seamless Round Tubes

Seamless Stainless Steel Tubing

Heavy Wall Stainless Steel Tubing

Purchase cut to size SS Seamless Round Tubes online with the most recent price list

| Wall Thickness mm OD mm |

0.5 | 0.6 | 0.7 | 0.8 | 1.0 | 1.2 | 1.6 | 2.0 | 2.6 | 3.0 | 3.2 | 3.6 |

| 6.0 | 0.069 | 0.081 | 0.093 | 0.104 | 0.125 | 0.144 | 0.176 | – | – | – | – | – |

| 10.0 | 0.119 | 0.141 | 0.163 | 0.184 | 0.225 | 0.264 | 0.336 | – | – | – | – | – |

| 12.7 | 0.153 | 0.182 | 0.210 | 0.238 | 0.293 | 0.345 | 0.444 | – | – | – | – | – |

| 14.0 | 0.169 | 0.201 | 0.233 | 0.264 | 0.325 | 0.384 | 0.496 | – | – | – | – | – |

| 15.87 | 0.192 | 0.229 | 0.266 | 0.301 | 0.372 | 0.440 | 0.571 | 0.694 | – | – | – | – |

| 19.0 | 0.231 | 0.276 | 0.320 | 0.364 | 0.450 | 0.534 | 0.696 | 0.850 | 1.066 | 1.200 | 1.264 | – |

| 25.0 | 0.306 | 0.366 | 0.425 | 0.484 | 0.600 | 0.714 | 0.936 | 1.150 | 1.456 | 1.650 | 1.744 | 1.926 |

| 25.4 | 0.311 | 0.372 | 0.432 | 0.492 | 0.610 | 0.726 | 0.952 | 1.170 | 1.482 | 1.680 | 1.776 | 1.962 |

| 31.75 | – | – | – | – | – | 0.918 | 1.208 | 1.490 | 1.898 | 2.160 | 2.288 | 2.538 |

| 38.0 | – | – | – | – | – | 1.104 | 1.456 | 1.800 | 2.301 | 2.625 | 2.784 | 3.096 |

| 44.5 | – | – | – | – | – | 1.299 | 1.716 | 2.125 | 2.724 | 3.113 | 3.304 | 3.681 |

| 50.8 | – | – | – | – | – | – | 1.968 | 2.440 | 3.133 | 3.585 | 3.808 | 4.248 |

| 63.5 | – | – | – | – | – | – | 2.476 | 3.075 | 3.959 | 4.538 | 4.824 | 5.391 |

| 76.1 | – | – | – | – | – | – | 2.980 | 3.705 | 4.778 | 5.483 | 5.832 | 6.525 |

| 101.6 | – | – | – | – | – | – | 4.000 | 4.980 | 6.435 | 7.395 | 7.872 | 8.820 |

| 114.3 | – | – | – | – | – | – | 4.453 | 5.547 | 7.173 | 8.247 | 8.780 | 9.840 |

| 127 | – | – | – | – | – | – | 4.955 | 6.175 | 7.989 | 9.188 | 9.785 | 10.980 |

| 152.4 | – | – | – | – | – | – | 5.960 | 7.429 | 9.620 | 11.070 | 11.792 | 13.231 |

| STANDARD | AFNOR | UNS | EN | JIS | BS | WNR | GOST |

|---|---|---|---|---|---|---|---|

| SA213 TP304 | Z7CN18‐09 | S30400 | X5CrNi18-10 | SUS 304 | 304S31 | 1.4301 | 08Х18Н10 |

| SA213 TP304L | Z3CN18‐10 | S30403 | X2CrNi18-9 / X2CrNi19-11 | SUS 304L | 3304S11 | 1.4306 / 1.4307 | 03Х18Н11 |

| SA213 TP304H | – | S30409 | – | – | – | 1.4301 | – |

| SA213 TP310 | – | S31000 | X15CrNi25-20 | SUS 310 | 310S24 | 1.4841 | 20Ch25N20S2 |

| SA213 TP310S | – | S31008 | X8CrNi25-21 | SUS 310S | 310S16 | 1.4845 | 20Ch23N18 |

| SA213 TP310H | – | S31009 | – | – | – | – | – |

| SA213 TP316 | Z7CND17‐11‐02 | S31600 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | SUS 316 | 316S31 / 316S33 | 1.4401 / 1.4436 | – |

| SA213 TP316L | Z3CND17‐11‐02 / Z3CND18‐14‐03 | S31603 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 | SUS 316L | 316S11 / 316S13 | 1.4404 / 1.4435 | 03Ch17N14M3 / 03Ch17N14M2 |

| SA213 TP316H | – | S31609 | – | – | – | 1.4401 | – |

| SA213 TP316Ti | Z6CNDT17‐123 | S31635 | X6CrNiMoTi17-12-2 | SUS 316Ti | 320S31 | 1.4571 | 08Ch17N13M2T |

| SA213 TP317 | – | S31700 | – | SUS 317 | – | 1.4449 | – |

| SA213 TP317L | – | S31703 | X2CrNiMo18-15-4 | SUS 317L | – | 1.4438 | – |

| SA213 TP321 | – | S32100 | X6CrNiTi18-10 | SUS 321 | – | 1.4541 | – |

| SA213 TP321H | – | S32109 | X12CrNiTi18-9 | SUS 321H | – | 1.4878 | – |

| SA213 TP347 | – | S34700 | X6CrNiNb18-10 | SUS 347 | – | 1.4550 | 08Ch18N12B |

| SA213 TP347H | – | S34709 | X6CrNiNb18-12 | SUS 347H | – | 1.4961 | – |

| SA213 TP904L | Z2 NCDU 25-20 | N08904 | X1NiCrMoCu25-20-5 | SUS 904L | 904S13 | 1.4539 | STS 317J5L |

Cold drawn process enhances the dimensional accuracy of Seamless Stainless Steel Tubing.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Ti | Fe | |

| SA213 TP304 | min. | 18.0 | 8.0 | |||||||||

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | 0.10 | ||||

| SA213 TP304L | min. | 18.0 | 8.0 | |||||||||

| max. | 0.030 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 12.0 | 0.10 | ||||

| 304H | min. | 0.04 | 18.0 | 8.0 | ||||||||

| max. | 0.010 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | |||||

| SA213 TP316 | min. | 16.0 | 2.03.0 | 10.0 | ||||||||

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| SA213 TP316L | min. | 16.0 | 2.0 – 3.0 | 10.0 | ||||||||

| max. | 0.035 | 2.0 | 0.75 | 0.045 | 0.030 | 18.0 | 14.0 | |||||

| SA213 TP316Ti | 0.08 max | 10.00 14.00 | 2.0 max | 0.045 max | 0.030 max | 16.00 18.00 | 0.75 max | 2.00 3.00 | ||||

| SA213 TP317 | 0.08 max | 2 max | 1 max | 0.045 max | 0.030 max | 18.00 20.00 | 3.00 4.00 | 57.845 min | ||||

| SA213 TP317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 20.00 | 3.00 4.00 | 11.00 15.00 | 57.89 min | |||

| SA213 TP321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 19.00 | 9.00 12.00 | 0.10 max | 5(C+N) 0.70 max | |||

| SS 321H | 0.04 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 19.00 | 9.00 12.00 | 0.10 max | 4(C+N) 0.70 max | |||

| SA213 TP347 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 20.00 | 9.0013.00 | |||||

| SA213 TP410 | min. | 11.5 | ||||||||||

| max. | 0.15 | 1.0 | 1.00 | 0.040 | 0.030 | 13.5 | 0.75 | |||||

| 446 | min. | 23.0 | 0.10 | |||||||||

| max. | 0.2 | 1.5 | 0.75 | 0.040 | 0.030 | 30.0 | 0.50 | 0.25 | ||||

| SA213 TP904L | min. | 19.0 | 4.00 | 23.00 | 0.10 | |||||||

| max. | 0.20 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 5.00 | 28.00 | 0.25 | |||

| Grade | Elongation | Density | Yield Strength (0.2%Offset) | Melting Point | Tensile Strength |

| SA213 TP304 / SA213 TP304L | 35 % | 8.0 g/cm3 | Psi 30000 , MPa 205 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 |

| 304H | 40 % | 8.0 g/cm3 | Psi 30000 , MPa 205 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 |

| SA213 TP310 | 40 % | 7.9 g/cm3 | Psi 30000 , MPa 205 | 1402 °C (2555 °F) | Psi 75000 , MPa 515 |

| SA213 TP316 / 316H | 35 % | 8.0 g/cm3 | Psi 30000 , MPa 205 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 |

| SA213 TP316L | 35 % | 8.0 g/cm3 | Psi 30000 , MPa 205 | 1399 °C (2550 °F) | Psi 75000 , MPa 515 |

| SA213 TP317 | 35 % | 7.9 g/cm3 | Psi 30000 , MPa 205 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 |

| SA213 TP321 | 35 % | 8.0 g/cm3 | Psi 30000 , MPa 205 | 1457 °C (2650 °F) | Psi 75000 , MPa 515 |

| SA213 TP347 | 35 % | 8.0 g/cm3 | Psi 30000 , MPa 205 | 1454 °C (2650 °F) | Psi 75000 , MPa 515 |

| SA213 TP904L | 35 % | 7.95 g/cm3 | Psi 32000 , MPa 220 | 1350 °C (2460 °F) | Psi 71000 , MPa 490 |

We keep stock of Heavy Wall Stainless Steel Tubing in many standards and finishes

- Mill Finish

- Polished Finish

- Brushed Finish

- Mirror Finish

- Embossed Finish

- Colored Finish

- Flattening Test

- Micro and MacroTest

- Hardness Test

- Testing

- Pitting Resistance Test

- Chemical Analysis

- Intergranular Corrosion Test

- Positive Material Identification

- Flaring Test

Application of Stainless steel tubing

- Sea Water Equipment

- Pulp and Paper Industry

- Power Generation

- Specialty Chemicals

- Chemical Equipment

- Petrochemicals

- Gas Processing

- Pharmaceutical Equipment

Packaging of SS tube

SS tube undergo packaging procedures to guarantee their safety and prevent any damage while being transported. When dealing with exports, standard export packaging is utilized, which involves the use of wooden cases. Each elbow fitting is clearly marked with essential information such as Grade, Lot Number, Size, Degree, and our trademark. Additionally, upon specific requests, we can provide custom markings on our products.

Frequently asked questions

Available sizes and thickness of ss tubes

Size Range: 1/2″ to 4″

Thickness: SCH 10 to SCH XXS

Does wall thickness affects pressure rating of stainless steel seamless tubes

Yes, Wall thickness affects the pressure rating of tubes. Higher the wall thickness larger the pressure SS seamless tubes can withstand.

In which finishes stainless steel tubing are available?

- Mill Finish

- No. 1 Finish

- No. 2D Finish

- BA Finish

- Temper Rolled Finish

- Bright Finish

What is permissible temperature range of Heavy Wall Stainless Steel Tubing?

It is upto 870°C (1600°F) for continuous exposure.

Different welding techniques recommended for Seamless Stainless Steel Tubing

- TIG Welding

- MIG Welding

- SMAW Welding

- Flux-Cored Arc Welding