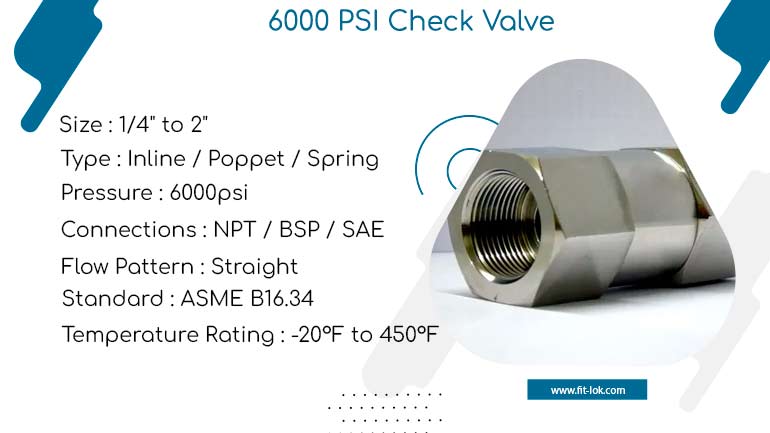

Reliable 400 Bar Inline Check Valve Manufacturer in India

We are trusted exporter and stockist of Male X Female 6000 psi Check Valve

Table of content

- 6000 PSI Check Valve Specification

- Types of 400 Bar Check Valve

- 6000 psi inline check valve price list

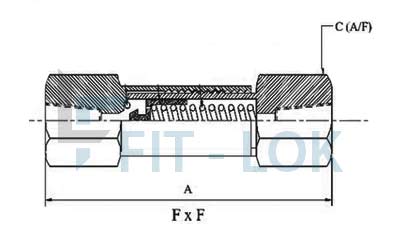

- Part of 6000 PSI Stainless Check Valve

- Working Temperature of 6000 Psi Water Check Valve

- Technical Data of 400 Bar Piston Check Valve

- Manufacturing standard of Check Valve 6000 Psi

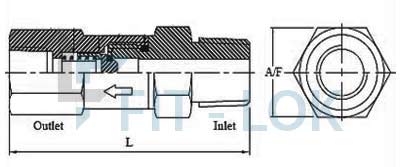

- Dimensions of 6000 psi Male X Female Check Valve

- Dimensions of 6000 psi Male X Male Check Valve

- Dimensions of 400 Bar Female X Female Check Valve

- Stock list of 6000 PSI Check Valve

- Application of Female X Female 6000 psi Check Valve

- Male X Female 6000 psi Check Valve Benefits

| Size Range |

|

| Connection |

|

| Threads |

|

| Body Shape | Hexagon |

| Pattern Flow | Straight |

| Orifice Size | 2 MM – 40 MM |

| Equivalent Brands |

|

| Pressure Rating |

|

| Cracking Pressure | 0.5 BAR |

| Type |

|

| Media |

|

| Body Type | Forged, Bar Stock |

| Packing Details |

|

400 Bar Check Valve

6000 psi inline check valve

6000 Psi Stainless Steel Water Check Valve

Female X Female 6000 psi Check Valve

Male X Female 6000 psi Check Valve

Male X Male 6000 psi Check Valve

Refer price list and sizes of 6000 psi inline check valve

Price of 6000 PSI check valve vary between 15$ to 150$ per piece based on size, material, pressure rating, design and flow rate. For updated price list of 400 Bar check valves you can contact us on sales@fit-lok.com

| Component | Material |

| Body | SS 316 |

| Seat Seal | Viton |

| Poppet | SS 316 |

| Spring Guide | SS 316 |

| Spring | SS 316 |

| Joint Seal | Viton |

| Stopper | SS 316 |

| Adaptor | SS 316 |

6000 PSI Stainless Check Valve can withstand temperature upto -40 up to +200 °C

| Working Temperature | -26°C to +190°C |

|---|

| Nominal Cracking Pressure | |

| Fixed | 1/3- 25 psi (0.02 – 1.07 bar) |

| Adjustable | 3 – 600 psi (0.21 – 41.04 bar) |

| Body Material | brass, 316 stainless steel |

| Seal Material | Buna N, Fluorocarbon FKM |

| Flow Coefficient | 0.010 – 4.07 |

Buy from a certified Male X Male 6000 psi Check Valve supplier in Mumbai

- ASME B16.34

- API 6D / API 598

- ASME B16.10

- MSS SP-25

- ASME B16.5

- MSS SP-55

- BS 1868

| PRESSURE RATING 100°F (37°C) PSIG | END CONNECTIONS | DIMENSIONS MM | Cv | ||

| INLET / OUT LET | L | A/F | |||

| 6000 | MALE x FEMALE NPT | 1/8″ | 60 | 19 | 0.82 |

| 6000 | 1/4″ | 68 | 22 | 1.40 | |

| 6000 | 3/8″ | 70 | 25 | 1.52 | |

| 6000 | 1/2″ | 82 | 27 | 1.70 | |

| 6000 | 3/4″ | 85 | 36 | 4.85 | |

| 6000 | 1″ | 92 | 45 | 8.30 | |

| PRESSURE RATING 100°F (37°C) PSIG | END CONNECTIONS | DIMENSIONS MM | Cv | ||

| INLET / OUT LET | L | A/F | |||

| 6000 | MALE x MALE NPT | 1/8″ | 60 | 19 | 0.82 |

| 6000 | 1/4″ | 68 | 22 | 1.40 | |

| 6000 | 3/8″ | 70 | 25 | 1.52 | |

| 6000 | 1/2″ | 82 | 27 | 1.70 | |

| 6000 | 3/4″ | 85 | 36 | 4.85 | |

| 6000 | 1″ | 92 | 45 | 8.30 | |

| PRESSURE RATING 100°F (37°C) PSIG | END CONNECTIONS | DIMENSIONS MM | Cv | ||

| INLET / OUT LET | L | A/F | |||

| 6000 | FEMALE x FEMALE NPT | 1/8″ | 55 | 19 | 0.78 |

| 6000 | 1/4″ | 58 | 22 | 1.31 | |

| 6000 | 3/8″ | 58 | 25 | 1.52 | |

| 6000 | 1/2″ | 65 | 27 | 1.68 | |

| 6000 | 3/4″ | 70 | 36 | 4.85 | |

| 6000 | 1″ | 82 | 45 | 8.30 | |

| 1/4″ STAINELSS STEEL CHECK VALVE 6000 PSI BSPT | 6000 Psi Stainless Steel Water Check Valve |

| Male X Male 6000 psi Check Valve | 3/8″ SS CHECK VALVE 6000 PSI BSPT |

| 6000 Psi Stainless Steel Water Check Valve | Male X Female 6000 psi Check Valve |

| 1/2″ AISI 304 CHECK VALVE 6000 PSI BSPT | 6000 psi inline check valve |

| 3/4″ Stainless steel 304L CHECK VALVE 6000 PSI BSPT | Female X Female 6000 psi Check Valve |

| 1″ STAINELSS STEEL 316 CHECK VALVE 6000 PSI BSPT | 400 Bar Check Valve |

- Oil and Gas Industry

- Hydraulic Systems

- Nuclear Power Plants

- High-Pressure Chemical Processing

- Offshore Industry

- Industrial Pressure Systems

- Firefighting Equipment

- Cryogenic Systems

- Increased Operational Efficiency

- Enhanced System Safety

- Protection of Equipment

- Durability Under High Pressure

- Corrosion and Wear Resistance

- Low operating Torques